Difference between revisions of "Projects:2018s1-122 NI Autonomous Robotics Competition"

| Line 15: | Line 15: | ||

== Project Description == | == Project Description == | ||

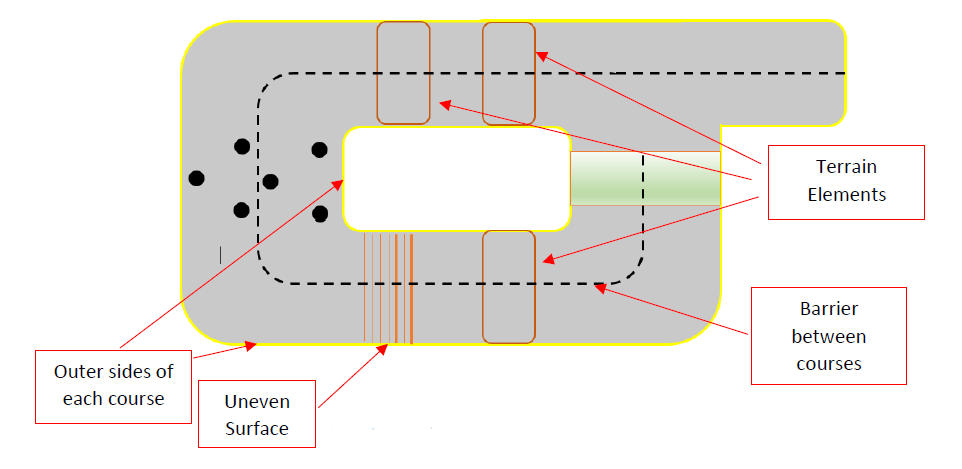

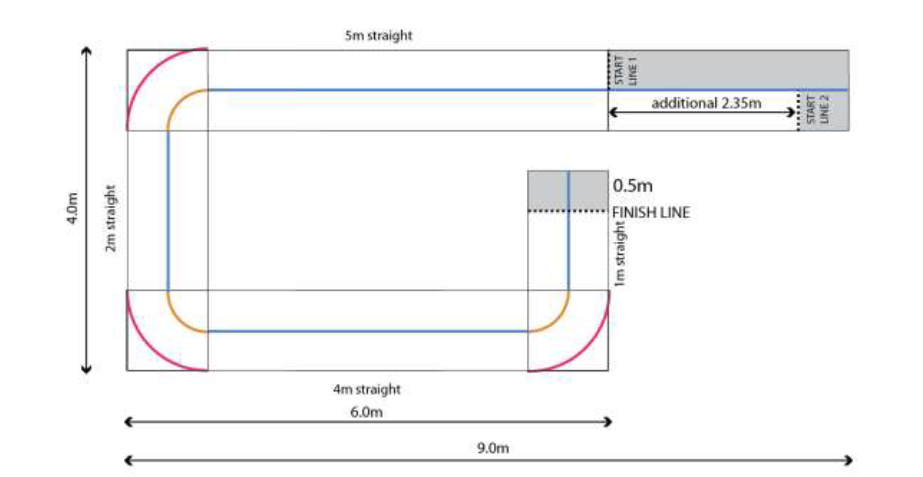

Each year, National Instruments (NI) sponsors a competition to showcase the robotics capabilities of students by | Each year, National Instruments (NI) sponsors a competition to showcase the robotics capabilities of students by | ||

| − | building autonomous robots using one of their | + | building autonomous robots using one of their reconfigurable processor and FPGA products. In 2018, the competition focuses |

| − | on the theme 'Fast Track to the Future' where | + | on the theme 'Fast Track to the Future' where robots must perform various tasks on a track that incorporates various hazardous terrain, and unforeseen obstacles to be avoided autonomously. |

| − | This project investigates the use of the NI MyRIO-1900 | + | This project investigates the use of the NI MyRIO-1900 platform to achieve autonomous localisation, path planning, and environmental awareness. The live final took place in September where university teams across Australia, New Zealand, and Asia competed against each other. |

| − | |||

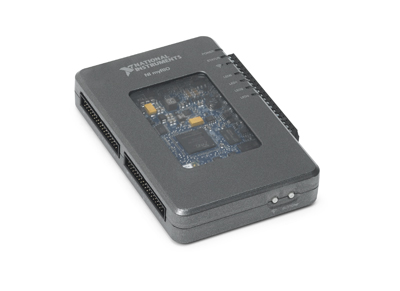

== Processing Platform == | == Processing Platform == | ||

| − | MyRIO - 1900 | + | MyRIO - 1900 containing a dual core ARM processor and Xilinx Zynq FPGA. |

| − | + | [[File:myrio.jpg]] | |

== Programming Environment == | == Programming Environment == | ||

| − | MyRIO | + | MyRIO processor and FPGA are programmed using LabVIEW graphical programming environment. |

== Robot Sensors == | == Robot Sensors == | ||

| Line 34: | Line 33: | ||

The sensors used: | The sensors used: | ||

| − | * Image sensor: | + | * Image sensor: Logitech C922 webcam |

| − | * Range sensors: ultrasonic | + | * Range sensors: ultrasonic & VL53LOX time of flight sensors |

| − | * Motor rotation sensors: motor encoders | + | * Motor rotation sensors: motor encoders package |

=== Image Sensor === | === Image Sensor === | ||

| Line 42: | Line 41: | ||

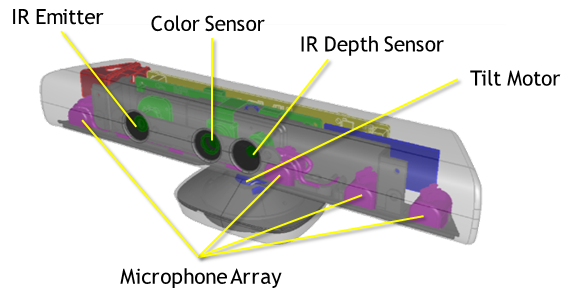

This camera produces two types of images: RGB images and depth (range) images. The RGB images consist of three channels: red, green, and blue. The depth images are represented with one channel, with each pixel value representing the distance from the camera to the first obstruction encountered. | This camera produces two types of images: RGB images and depth (range) images. The RGB images consist of three channels: red, green, and blue. The depth images are represented with one channel, with each pixel value representing the distance from the camera to the first obstruction encountered. | ||

| − | [[File:Kinect 01.jpg]] | + | [[File:Kinect 01.jpg]] <!-- Replace with Logitech webcam images--> |

[[File:Kinect.png]] | [[File:Kinect.png]] | ||

| Line 67: | Line 66: | ||

#Calculate equations of the lines that run through the edges | #Calculate equations of the lines that run through the edges | ||

| − | + | The produced line equations can be converted to obstacle locations referenced to the robot. Path planning can make decisions based on locations and the robot can avoid them just as it would avoid obstacles. | |

| − | |||

| − | |||

Revision as of 18:27, 17 October 2018

Contents

Supervisors

Dr Hong Gunn Chew

Dr Braden Phillips

Honours Students

Alexey Havrilenko

Bradley Thompson

Joseph Lawrie

Michael Prendergast

Project Description

Each year, National Instruments (NI) sponsors a competition to showcase the robotics capabilities of students by building autonomous robots using one of their reconfigurable processor and FPGA products. In 2018, the competition focuses on the theme 'Fast Track to the Future' where robots must perform various tasks on a track that incorporates various hazardous terrain, and unforeseen obstacles to be avoided autonomously. This project investigates the use of the NI MyRIO-1900 platform to achieve autonomous localisation, path planning, and environmental awareness. The live final took place in September where university teams across Australia, New Zealand, and Asia competed against each other.

Processing Platform

MyRIO - 1900 containing a dual core ARM processor and Xilinx Zynq FPGA.

Programming Environment

MyRIO processor and FPGA are programmed using LabVIEW graphical programming environment.

Robot Sensors

The robot requires a variety of sensors so that it may "see" track obstacles and boundaries, and so the robot may know its location within the track.

The sensors used:

- Image sensor: Logitech C922 webcam

- Range sensors: ultrasonic & VL53LOX time of flight sensors

- Motor rotation sensors: motor encoders package

Image Sensor

A camera is used as one of the various sensors for the purpose of determining accurate position and target location estimations. The Microsoft Xbox 360 Kinect Sensor USB 2.0 camera is an ideal candidate for the robot's vision because of it's capabilities, availability, and cost. This camera produces two types of images: RGB images and depth (range) images. The RGB images consist of three channels: red, green, and blue. The depth images are represented with one channel, with each pixel value representing the distance from the camera to the first obstruction encountered.

RGB Image Processing

The competition requires the robot to use the colour images for the following purposes:

- Identify boundaries on the floor that are marked with 50mm wide coloured tape

- Identify wall boundaries

Such processing will be taxing on the processor. Fortunately the myRIO contains an FPGA that can be used instead. This

The competition track boundaries are marked on the floor with 50mm wide coloured tape. The RGB images are processed to extract useful information. Before any image processing was attempted on the myRIO, the pipeline was determined using Matlab and its processing toolbox.

Determining Image Processing Pipeline in Matlab

An overview of the pipeline is as follows:

- Import/read captured RGB image

- Convert RGB (Red-Green-Blue) to HSV (Hue-Saturation-Value)

- The HSV representation of images allows us to easliy: isolate particular colours (Hue range), select colour intensity (Saturation range), and select brightness (Value range)

- Produce mask around desired colour

- Erode mask to reduce noise regions to nothing

- Dilate mask to return mask to original size

- Isolate edges of mask

- Calculate equations of the lines that run through the edges

The produced line equations can be converted to obstacle locations referenced to the robot. Path planning can make decisions based on locations and the robot can avoid them just as it would avoid obstacles.