Difference between revisions of "Projects:2016s2-245 RFID in a Light Bulb"

(→background) |

|||

| Line 39: | Line 39: | ||

As an important part of energy harvester, the electret is the core component of electrostatic energy harvester. It is a dielectric material, which has dipole polarisation or a permanent electric charge. It is similar like magnets that are dipoles. Many materials can be made into electret, most of them are made from synthetic polymers. It can be considered as stable direct current voltage source because there is a huge voltage potential in electret, which is an ideal alternative to DC voltage. However, the potential of electret is difficult to measure precisely at current stage, and it will decrease a lot in large time. | As an important part of energy harvester, the electret is the core component of electrostatic energy harvester. It is a dielectric material, which has dipole polarisation or a permanent electric charge. It is similar like magnets that are dipoles. Many materials can be made into electret, most of them are made from synthetic polymers. It can be considered as stable direct current voltage source because there is a huge voltage potential in electret, which is an ideal alternative to DC voltage. However, the potential of electret is difficult to measure precisely at current stage, and it will decrease a lot in large time. | ||

The structure of energy harvester, the permittivity of insulating material and the voltage potential of electret are the most important three factors which affect the energy generation. Therefore, this paper will put emphasis on these three factors. | The structure of energy harvester, the permittivity of insulating material and the voltage potential of electret are the most important three factors which affect the energy generation. Therefore, this paper will put emphasis on these three factors. | ||

| + | |||

| + | == '''Theory ''' == | ||

| + | |||

| + | Firstly, comparing to the mechanical motion, the demand of this project is the feature of unpredictable vibrations and in a relatively low frequency range. The piezoelectric devices and electromagnetic devices has high destination for frequency. Therefore, the electrostatic is suitable for meeting this requirement. At the same time, the unpredictable vibration dimension need to be considered. Even though the capacitance can be changed with varying the distance between two plates from relative motion of plates, the weakness is obvious in unpredictable dimensional vibration in random directions. Therefore, the liquid-based electrostatic energy harvester is adopted to solve above problem and improve sensitivity of device. | ||

| + | |||

| + | The structure of energy harvester is a capacitor in factor. According to the capacitance determination equation, C= εS/4πkd, which ε stands for permittivity, S stands for the area over the top and bottom plates, k stands for electrostatic force constant and the d stands for the distance between the top and bottom plates. Therefore, the capacitance can be changed by altering the permittivity of capacitor material, controlling the areas over two plates and adjusting the distance between two plates. This is the fundamental used in this paper to construct the energy harvester. | ||

| + | Moreover, according to the capacitance definition equation, C= (Q)/(U), which Q stands for the quantity of electric charge in plate and U stands for voltage between two plates. Therefore, with the changing of capacitance, and the quantity of electric charge in plate is constant, the voltage between two plates will be changed. Consequently, there is an alternative voltage generated over these two plates, which becomes a power supply to generate power to drive circuit. Hence, it is very important to find an effective way to change the capacitance significantly. The ratio of maximum over minimum is the key factor to affect the output energy power. The larger ratio is, the more power is generated, with the initial voltage unchanging. | ||

| + | |||

| + | The approach that putting sensitive conductive liquid in capacitor is effective to change the distance between two electrode plates. Furthermore, it can change the inner structure in the capacitor. Apart from the distance, the contacting area of the liquid and top plate is changed as well, as shown in Fig.2, obviously, the capacitor is changed from in series to in parallel. It can bring a larger capacitance when the conductive liquid moves from horizontal direction to vertical direction contacting with the top plates. | ||

| + | |||

| + | |||

| + | Besides the distance between two plates and contacting area of inner structure, the relative permittivity of material of each component is important as well. The components involve in this capacitor respectively are electret and insulating layer. The relative permittivity of material should be as larger as possible. The standard of choosing the material of insulating layer and side wall, there are some characteristic should be taken into consideration, such as, friction coefficient, adhesiveness, electrical insulating property, toxicity, corrosion resistance. In particularly, the low friction coefficient and low adhesiveness is essential for the sensitivity of capacitor and that is one of key factors to ensure feasibility of capacitor in low frequency range. | ||

| + | |||

| + | Secondly, the electret is used in this project to replace traditional voltage source. Electret cannot be removed from current like battery, however, it can provide a stable voltage, and it is therefore a good dc voltage source. In order to improve the portability of energy harvester, the simpler structure is necessary. The initial voltage could be provided by electret instead of external power supply. | ||

| + | |||

| + | The electret is made from some insulating material. It is like magnets to some extent and it has a permanent electric charge and can generate electrostatic field. However, there is an issue about the utility of electret that is the static electricity over the surface will discharge and result in the disappearance of surface potential at the same time. To be detailed, when the conducting liquid contacts directly with electret, it can discharge and cause the lifespan of energy harvester shorten significantly. Therefore, the polymer barrier layer is deposited between conducting liquid and electret surface can effectively protect the discharge conduction, and increase the lifespan to guarantee the charge storage stability and the performance of energy harvester. | ||

| + | |||

| + | Because of the uncertainty and uncontrollability during the charging process of the electret, the characteristic of electret cannot be specified. Under this situation, the outcome of experimental is instable. Therefore, the effect of instability should be taken into consideration. | ||

| + | |||

| + | Finally, the choice of conductive liquid is gallium (Ga). It is one kind of liquid metal that the melting point is under 29.8℃, the others are mercury that is the only liquid metal under room temperature and pressure and caesium that the melting point is under 28.4℃. even though the melting point of gallium is highest among these metals, the mercury and caesium are both toxic. Therefore, the gallium is the safest choice. | ||

Revision as of 20:48, 29 May 2017

Contents

project team

Academic Supevisors

Dr. Said Al-Sarawi

Dr. Damith Ranasinghe

team members

ZEYU WANG RAN YE

Introduction

the development of a permanent power source for self-sustainable wireless sensor networks is essential in order to reduce the maintenance costs and increase the operational time of sensor nodes. Accordingly,over the past decade researchers have actively studied various energy harvesters that generate power form sources such as ambient light, heat, motion, electromagnetic waves and other unused sources of energy. One energy harvester driven by ambient vibrations has attracted special attention because it can easily gain energy form sources of movement such as human physical motion. This project states a liquid-based electrostatic energy harvester that converts the mechanical energy of human-motion-induced vibrations to electrical energy.

Aims

This paper presents a kinetic energy electrostatic harvester with electret as voltage source and liquid-based structure, which converts the mechanical energy in a low working frequency vibration to electrical energy. Moreover, it addresses the discharge issue of electret to improving charge storage stability of electrets in liquid-based environment. Extending from the theoretical research, the prototype of energy harvester is fabricated in proposed structure and is tested its performance in desirable low frequency range. In addition, the high efficiency circuit is necessary in energy conversion that is as important as the capacitor part.

Motivation and Significance

Energy harvesting technologies present a developing self-sustainable power source to replace conventional batteries in portable and low consumable application such as autonomous wireless sensor nodes, low power consumption electronic devices, and implantable medical equipment. As an emerging inexhaustible power source, there is significant developing potential in energy harvesting from ambient energy sources. It is different from piezoelectric harvesters and electromagnetic harvesters, which are mostly designed in a resonant mode and are driven in a relatively high frequency range. For instance, the spring structures are used in energy harvester should overcome their natural frequency to excite the system operation. Therefore, it is difficult to use in a low frequency range. Additionally, the electrets discharge reason limit their usage when it contacts with liquid. The polymer barrier layer is proposed to solve its discharge issue.

Comparing to conventional energy source, energy harvester provides sustainable and clean energy source. Comparing to piezoelectric energy harvester and electromagnetic energy harvester, electrostatic energy harvester has high output voltages; their components are built in low-cost parts, is easy to adjust the coupling coefficient and reaches high coupling coefficients, and increases capacitances through the reduction of size. These advantages are significant in small-scale energy harvester and in low frequency range operation.

The energy harvester needs an initial voltage. The conventional power supply is external power source such as battery and DC power supply, which are inconvenient in portable application, and it will affect the volume of entire energy harvester. And at the same time, the electret replaces these conventional power supply as initial voltage is a crucial part of this energy harvester.

background

Initially, the principle of energy harvester is capacitor. The components of liquid-based energy harvester are composed of two electrodes, which is top and bottom metal plates; a cavity is to store liquid; a Polytetrafluoroethylene (PTFE) film layer is coated on the bottom of cavity. A barrier layer is used to solve electret discharge issue. The electret is used to provide the initial voltage for energy harvester. And the conducting liquid plays a role in changing the way that the arrangement mode of inner capacitors.

In this capacitor, the electret and the covered film are considered as insulating layer. Through changing the liquid state, the inside structure of capacitor is changed when there is an external vibration. When the liquid occasionally contacts with the top insulating layer, the capacitance becomes large due to the air gap is eliminated. To be detailed, the inside structure of capacitor is changed from series capacitance to parallel capacitance. The value of capacitance is expressed as:

Capacitance initial is the minimum capacitance, capacitance excited is the maximum capacitance. ε1 is the permittivity of PTFE electret, ε2 is the permittivity of air, ε_3 is the permittivity of Cellulose Acetate tape. The d1 is the thickness of PTFE, d2 is the thickness of air gap, d3 is the height of liquid, d4 is the thickness of Cellulose Acetate tape. S is the overlay area of the top and bottom plates, Sliquid is the contact area of the conducting liquid and the insulating layer.

As this formula expressed, the electrical energy generation is determined by the capacitance ratio, the maximum capacitance and the electret voltage. As an important part of energy harvester, the electret is the core component of electrostatic energy harvester. It is a dielectric material, which has dipole polarisation or a permanent electric charge. It is similar like magnets that are dipoles. Many materials can be made into electret, most of them are made from synthetic polymers. It can be considered as stable direct current voltage source because there is a huge voltage potential in electret, which is an ideal alternative to DC voltage. However, the potential of electret is difficult to measure precisely at current stage, and it will decrease a lot in large time. The structure of energy harvester, the permittivity of insulating material and the voltage potential of electret are the most important three factors which affect the energy generation. Therefore, this paper will put emphasis on these three factors.

Theory

Firstly, comparing to the mechanical motion, the demand of this project is the feature of unpredictable vibrations and in a relatively low frequency range. The piezoelectric devices and electromagnetic devices has high destination for frequency. Therefore, the electrostatic is suitable for meeting this requirement. At the same time, the unpredictable vibration dimension need to be considered. Even though the capacitance can be changed with varying the distance between two plates from relative motion of plates, the weakness is obvious in unpredictable dimensional vibration in random directions. Therefore, the liquid-based electrostatic energy harvester is adopted to solve above problem and improve sensitivity of device.

The structure of energy harvester is a capacitor in factor. According to the capacitance determination equation, C= εS/4πkd, which ε stands for permittivity, S stands for the area over the top and bottom plates, k stands for electrostatic force constant and the d stands for the distance between the top and bottom plates. Therefore, the capacitance can be changed by altering the permittivity of capacitor material, controlling the areas over two plates and adjusting the distance between two plates. This is the fundamental used in this paper to construct the energy harvester. Moreover, according to the capacitance definition equation, C= (Q)/(U), which Q stands for the quantity of electric charge in plate and U stands for voltage between two plates. Therefore, with the changing of capacitance, and the quantity of electric charge in plate is constant, the voltage between two plates will be changed. Consequently, there is an alternative voltage generated over these two plates, which becomes a power supply to generate power to drive circuit. Hence, it is very important to find an effective way to change the capacitance significantly. The ratio of maximum over minimum is the key factor to affect the output energy power. The larger ratio is, the more power is generated, with the initial voltage unchanging.

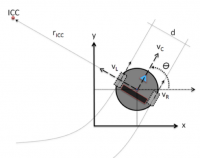

The approach that putting sensitive conductive liquid in capacitor is effective to change the distance between two electrode plates. Furthermore, it can change the inner structure in the capacitor. Apart from the distance, the contacting area of the liquid and top plate is changed as well, as shown in Fig.2, obviously, the capacitor is changed from in series to in parallel. It can bring a larger capacitance when the conductive liquid moves from horizontal direction to vertical direction contacting with the top plates.

Besides the distance between two plates and contacting area of inner structure, the relative permittivity of material of each component is important as well. The components involve in this capacitor respectively are electret and insulating layer. The relative permittivity of material should be as larger as possible. The standard of choosing the material of insulating layer and side wall, there are some characteristic should be taken into consideration, such as, friction coefficient, adhesiveness, electrical insulating property, toxicity, corrosion resistance. In particularly, the low friction coefficient and low adhesiveness is essential for the sensitivity of capacitor and that is one of key factors to ensure feasibility of capacitor in low frequency range.

Secondly, the electret is used in this project to replace traditional voltage source. Electret cannot be removed from current like battery, however, it can provide a stable voltage, and it is therefore a good dc voltage source. In order to improve the portability of energy harvester, the simpler structure is necessary. The initial voltage could be provided by electret instead of external power supply.

The electret is made from some insulating material. It is like magnets to some extent and it has a permanent electric charge and can generate electrostatic field. However, there is an issue about the utility of electret that is the static electricity over the surface will discharge and result in the disappearance of surface potential at the same time. To be detailed, when the conducting liquid contacts directly with electret, it can discharge and cause the lifespan of energy harvester shorten significantly. Therefore, the polymer barrier layer is deposited between conducting liquid and electret surface can effectively protect the discharge conduction, and increase the lifespan to guarantee the charge storage stability and the performance of energy harvester.

Because of the uncertainty and uncontrollability during the charging process of the electret, the characteristic of electret cannot be specified. Under this situation, the outcome of experimental is instable. Therefore, the effect of instability should be taken into consideration.

Finally, the choice of conductive liquid is gallium (Ga). It is one kind of liquid metal that the melting point is under 29.8℃, the others are mercury that is the only liquid metal under room temperature and pressure and caesium that the melting point is under 28.4℃. even though the melting point of gallium is highest among these metals, the mercury and caesium are both toxic. Therefore, the gallium is the safest choice.