Difference between revisions of "Projects:2014S1-01 Development of Fully Automated Educational and Training Tool for Wind and Solar Energy using National Instruments’ ELVIS Based System"

(→Power System Architecture) |

|||

| (67 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

| − | == Project | + | == Project Overview == |

| + | === Project Motivation === | ||

| + | Renewable energy is a fast growing industry. Training systems which are simple to operate, relatively easy to understand and cost effective will be vital in teaching those who move into this industry. | ||

| + | |||

| + | The current Distributed Generation Technologies (DGT) practical can be difficult to set up, and requires at least two multimeters and an oscilloscope to take measurements. It also only uses non-illuminated tests of the solar panel, which are not as accurate as illuminated characteristics. The experiment does not incorporate accurate sensor values to identify the relationship between environmental conditions and the characteristics of the generator. Commercially available options, such as the EMONA HELEX board [1], are very expensive and offer limited functionality. The university is in possession of an ELVIS system that allows for the development of circuit boards that can be directly connected to a 16 channel ADC and other useful digital and analogue outputs and inputs. An improved version of the EMONA board would be a great way to utilise this equipment to improve student learning through practical experience. | ||

| + | |||

=== Project Introduction === | === Project Introduction === | ||

| − | The aim of this project is to develop an | + | The main aim of this project is to develop an automated education and training tool for wind and solar energy using National Instruments’ ELVIS platform, initially for use in student practicals. The current distributed generation practicals can be difficult to perform, both in wiring correctly and getting accurate measurements. Commercially available alternatives are prohibitively expensive and have limited features. |

| − | === | + | |

| − | + | Using the wind and solar generation systems provided, a plug in board for the NI ELVIS platform was developed. The project started with an assessment of the hardware developed in previous projects, to determine what could be reused or improved. Following this, the new board was developed with a number of circuits which allow the characterisation of both wind and solar generators with load and different power electronic converters. Measurements are automatically carried out by integrated sensors which communicate with LabVIEW via the ELVIS platform, reducing the complexity of generator characterisation. | |

| − | The | + | |

| − | + | This project also sought to improve the external sensors utilised to measure environmental conditions. External microcontrollers were added to digitise sensor signals at the source and improve accuracy. Additional humidity and temperature sensors were calibrated for the wind setup. | |

| − | The | + | At this point in the project the microcontroller boards have been successfully produced and tested, the main board has been constructed and sensors have been calibrated, and the accompanying LabVIEW software to provide demonstrations has been developed. |

| + | === Previous Studies === | ||

| + | Previous work has been carried out on this project, which will be built upon. Students in previous years have developed the major parts of hardware which we will use for this project. This includes a solar panel system, containing a solar panel with an attached temperature sensor, a controlled light source and stepper motor to tilt the panel. There is also a wind tunnel containing a fan to generate wind, a three phase generator, and temperature and wind sensors. | ||

| + | === Objectives of the project === | ||

| + | The major aim of this project is to develop a printed circuit board (PCB) to plug into the ELVIS system which can be utilised using LabVIEW software to carry out renewable energy experiments. | ||

| + | |||

| + | This will involve: | ||

| + | |||

| + | • Developing sufficient circuitry to trace basic generator characteristics | ||

| + | |||

| + | • Developing circuitry to demonstrate principles of Maximum Power Point Tracking (MPPT) utilising power electronic converters | ||

| + | |||

| + | • Developing LabVIEW software to control experiments and measure and display values | ||

| + | |||

| + | == Hardware == | ||

| + | === Power System Architecture === | ||

| + | |||

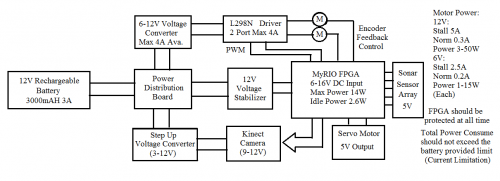

| + | As an essential requirement of electronic device, power must be provided in order to support all the internal components function well. Without power all the electronics would not be able to run, hence power is indispensible and the fundamental attributes of all the robots. For this specific autonomous robot system, power source should be portable and powerful enough to supply the main energy consumption from robot’s motion system, as well as supporting all the other components in various situations. When considered about power system design, it could generally be developed into three sessions: overall power system design, selection of power source and detail design of the power circuits. | ||

| + | |||

| + | [[File:Robot Power System Design2.png|500px|thumb|right|Robot Power System Design]] | ||

| + | |||

| + | The diagram above illustrates the architecture of our robot power system. In order to satisfy the mobile and portable requirements of the autonomous robot, we would be using DC battery as the main power source. The battery output connects into a power distribution board, which then separates into multiple channels, for our distribution board we have implemented 5 different channels for future applications.there are only three main channels presented in the diagram. | ||

| + | |||

| + | One channel is designed for the locomotion system only as it's the largest power consumption system of our robot.The gear motor would have the potentials of drawing very high current at stall situations, so we consider the worst condition that if both of the motor is stalling at maximum speed operations, which would draw up to 5Amps current and the distribution board should be able to sustain without causing any damages or instabilities. | ||

| + | |||

| + | The second channel is dedicated for the MyRIO device only, as it's the most important yet vulnerable components of the entire robot system, so we designed it to be isolated from the other channels which would be able to minimize the interferences from other channels, as well as protecting from instantaneous surge current causing by the motors and other components. | ||

| + | |||

| + | The third channel is allocated to the Kinect camera (sensor), since its small voltage range support we have discussed before, even though it's a well integrated module and robust for power variation, it still needs stable power condition to operate properly. | ||

| + | |||

| + | === Wind System === | ||

| + | The wind system includes the electric fan, fan controller, wind external micro-controller, wind speed sensor, humidity sensors and temperature sensors. | ||

| + | |||

| + | the wind tunnel provides the uniform wind for testing. The electric fan is on top of the wind tunnel. The electric fan is controlled by LabVIEW through external wind micro-controller. The electric fan can provide the wind power to the wind turbine. | ||

| + | |||

| + | [[File:Wind_Tunnel.jpg|400px]] | ||

| + | |||

| + | '''Wind Tunnel''' | ||

| + | |||

| + | |||

| + | A variable pitch propeller and motor set is used for the generator initially. The set used for the test is a 1600KV motor and a 10-inch diameter propeller. It generates power at 1600rpm/V. The wind turbine is controlled by LabVIEW and the three phase AC power signal will be sent to the main board for further test. | ||

| + | |||

| + | The wind power generated by the wind turbine can be calculated from the equation P=1/2 ρAC_p v^3, where P represents the power generated by the wind power; ρ represents the air density; C_p represents the efficiency of the wind turbine; A represents the swept area of blades and v represents the wind speed. Humidity and temperature affect the value of air density. Therefore, wind speed sensor, humidity sensor and temperature sensor are required for the wind system to calculate the efficiency of the wind turbine and take further tests. The wind speed sensor is located at the exit of the wind tunnel, right in front of the wind turbine, to get accurate wind speed near the wind turbine. The temperature and humidity sensor are located on top of the exit of the wind tunnel. | ||

| + | |||

| + | |||

| + | [[File:Sensors.jpg|400px]] | ||

| + | |||

| + | '''Sensors for Wind System''' | ||

| + | |||

| + | |||

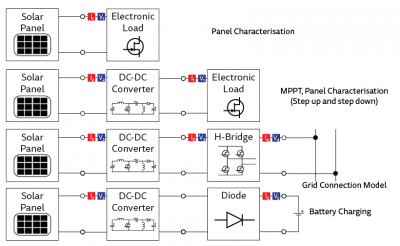

| + | === Experiments using the Board === | ||

| + | |||

| + | {| | ||

| + | | '''Solar''' | ||

| + | |- | ||

| + | |[[File:SOLAR.png|400px|thumb|left]] | ||

| + | |- | ||

| + | | '''Wind''' | ||

| + | |- | ||

| + | |[[File:WIND.png|400px|thumb|left]] | ||

| + | |} | ||

| + | <gallery widths=150px heights=150px caption="Circuits"> { | ||

| + | mosfetLoad.png | A variable resistance load which can also be controlled as a constant voltage or constant current load. | ||

| + | Dc-dc.png | A buck-boost dc-dc converter allows a DC input voltage to be stepped up and down. | ||

| + | Fixed-load.png | The fixed load section allows PCBs with different R, RL and RC loads to be connected to investigate current and voltage characteristics. | ||

| + | Battery-charger.png | This section provides a DC output from the board, measured by current and voltage sensors. A diode protects the board from the reverse flow of current. | ||

| + | 3ph.png | A three phase sensor block measures the line voltages using differential amplifiers and the line currents using current shunt monitors. | ||

| + | Inverter.png | A MOSFET based inverter topology is used on our PCB as a controlled three-phase rectifier, allowing the wind turbine output to be used with the DC-DC converter and MOSFET load. | ||

| + | H-bridge.png | The H-bridge circuit allows AC to be generated from the DC output of the solar panel or rectifier, modelling grid connection. | ||

| + | |} | ||

| + | </gallery> | ||

| + | |||

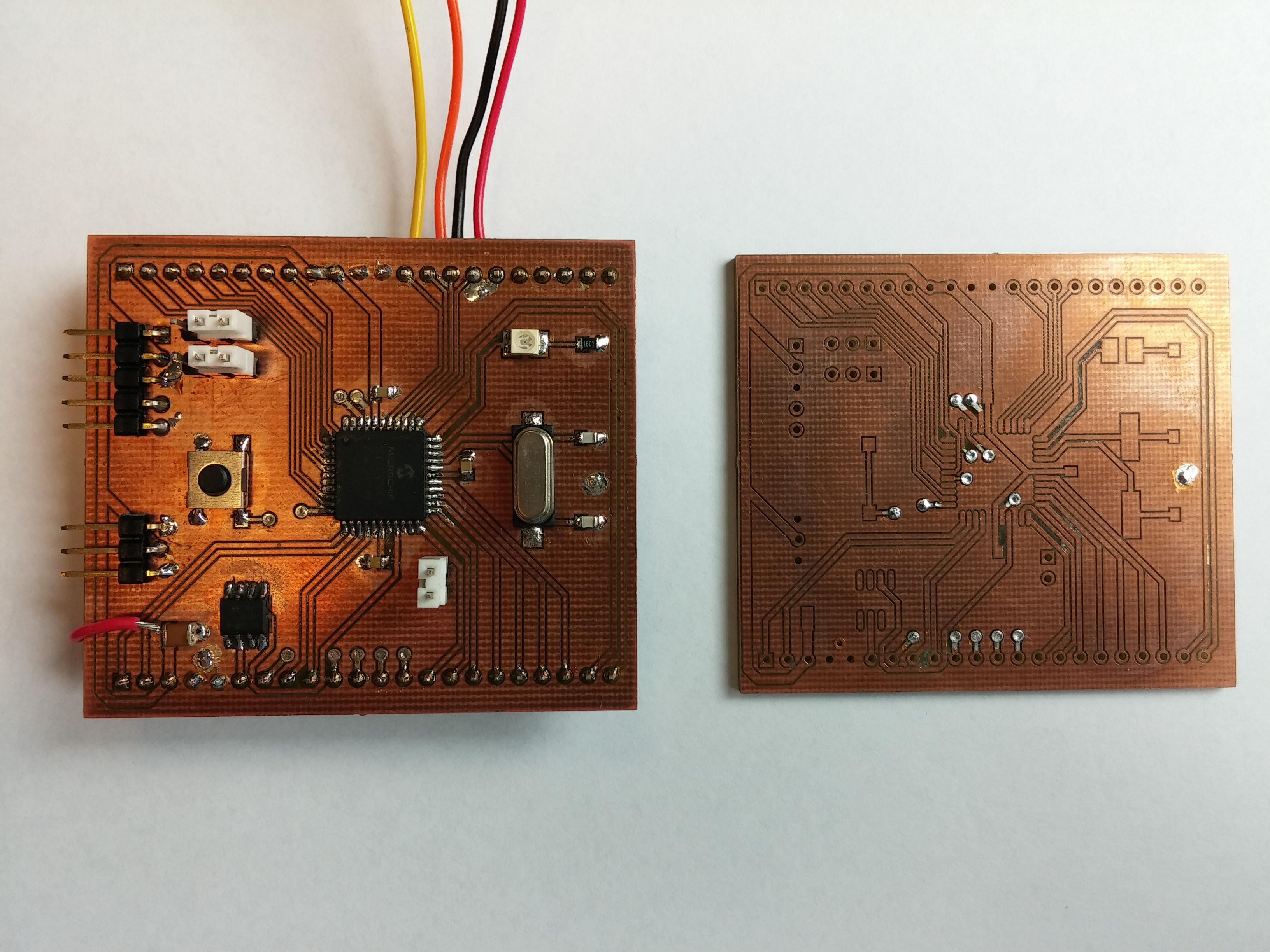

| + | === Microcontroller Boards === | ||

| + | ==== Plug-In Microcontroller Board ==== | ||

| + | The purpose of the plug-in microcontroller board is to provide the control signals for the modules on the main board. It was designed as a separate board so that it could be easily interchanged with different microcontroller boards. Also this allowed for easier testing and replacement. The PIC24FV16KM204 was chosen as the microcontroller for the plug-in board. Commands from LabVIEW are sent over SPI. | ||

| + | |||

| + | The plug-in board has sixteen analogue inputs, to sense all the main board voltages and currents. It has ten outputs for controlling the circuits on the main board. | ||

| + | |||

| + | [[File:Group_01_-_Plug_In_Boards.jpg | frame | centre | x300px | Plug-in Microcontroller Board ]] | ||

| + | |||

| + | |||

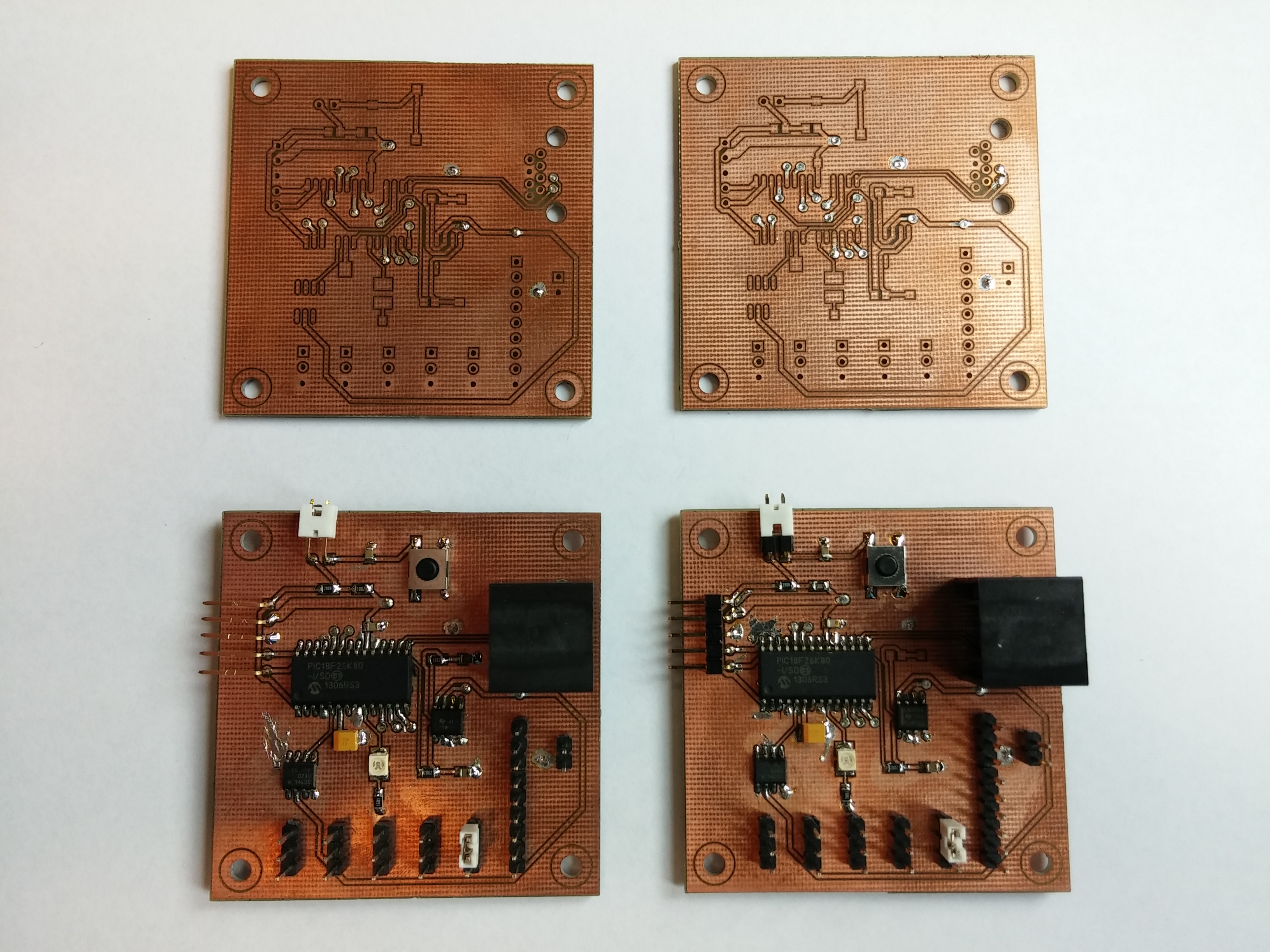

| + | ==== External Microcontroller Board ==== | ||

| + | The purpose of the external microcontroller boards is to perform analogue-to-digital functions on the external sensors (e.g. wind speed sensor), control the external parameters of each system (e.g. solar panel angle). Commands from LabVIEW are sent over SPI. The sensor values are sent back to LabVIEW over SPI. A generic external board was designed, so that it could be used with both the wind and solar system. The PIC18F26K80 was chosen as the microcontroller for the external boards. | ||

| + | |||

| + | The board has five sensor inputs and external pins. Each of these has a ground pin, +5V supply pin and an input signal pin. A +5V voltage reference IC is powered from +15V to provide a reference for analogue-to-digital conversions. The board has an analogue output with a gain that can be set with an on-board operational amplifier. The board also has general purpose input/output pins. | ||

| + | |||

| + | [[File:Group_01_-_External_Boards.jpg | frame | centre | x300px | External Microcontroller Boards ]] | ||

| + | |||

| + | == LabVIEW Software == | ||

| + | === Quiz === | ||

| + | <p>A quiz program was developed to be integrated into the main program. It will test students’ knowledge of basic concepts before the experiment.</p> | ||

| + | |||

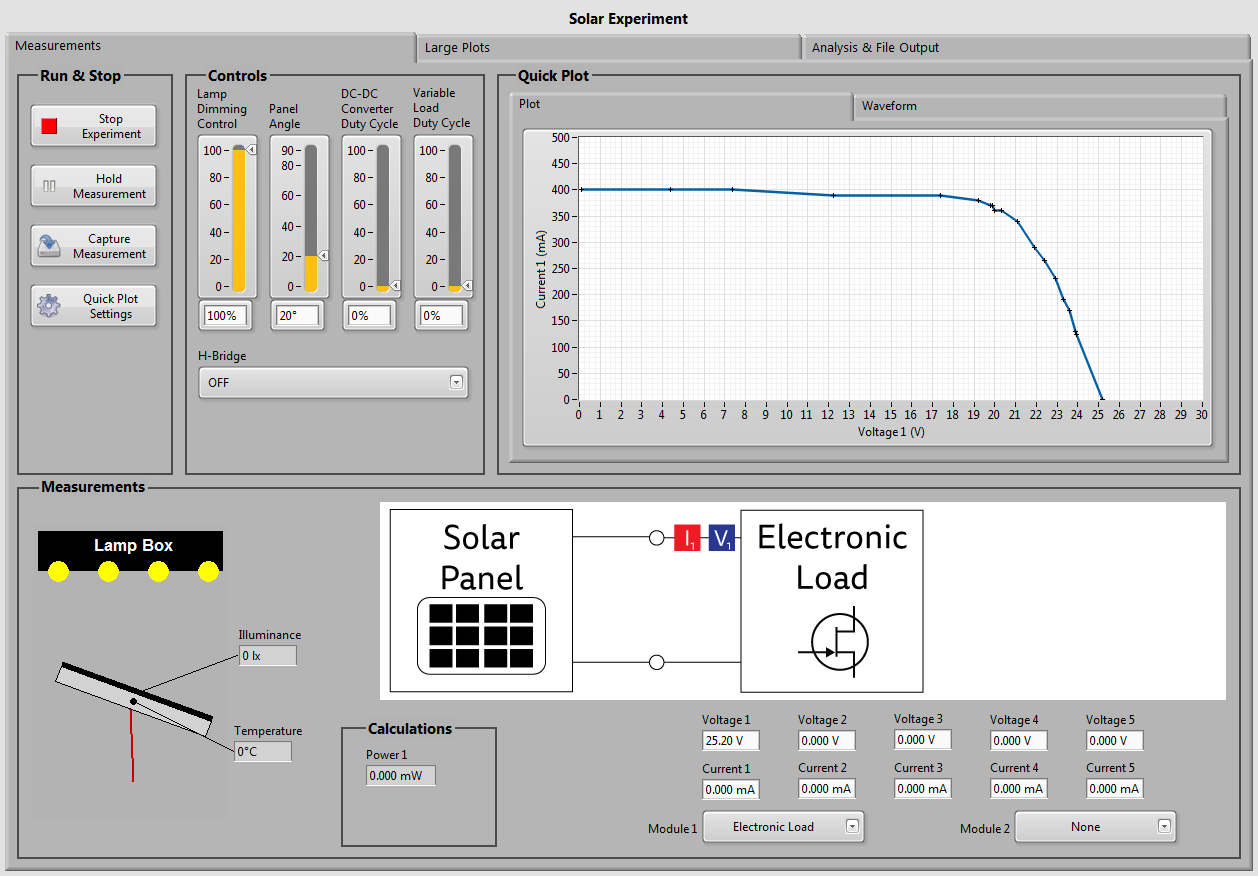

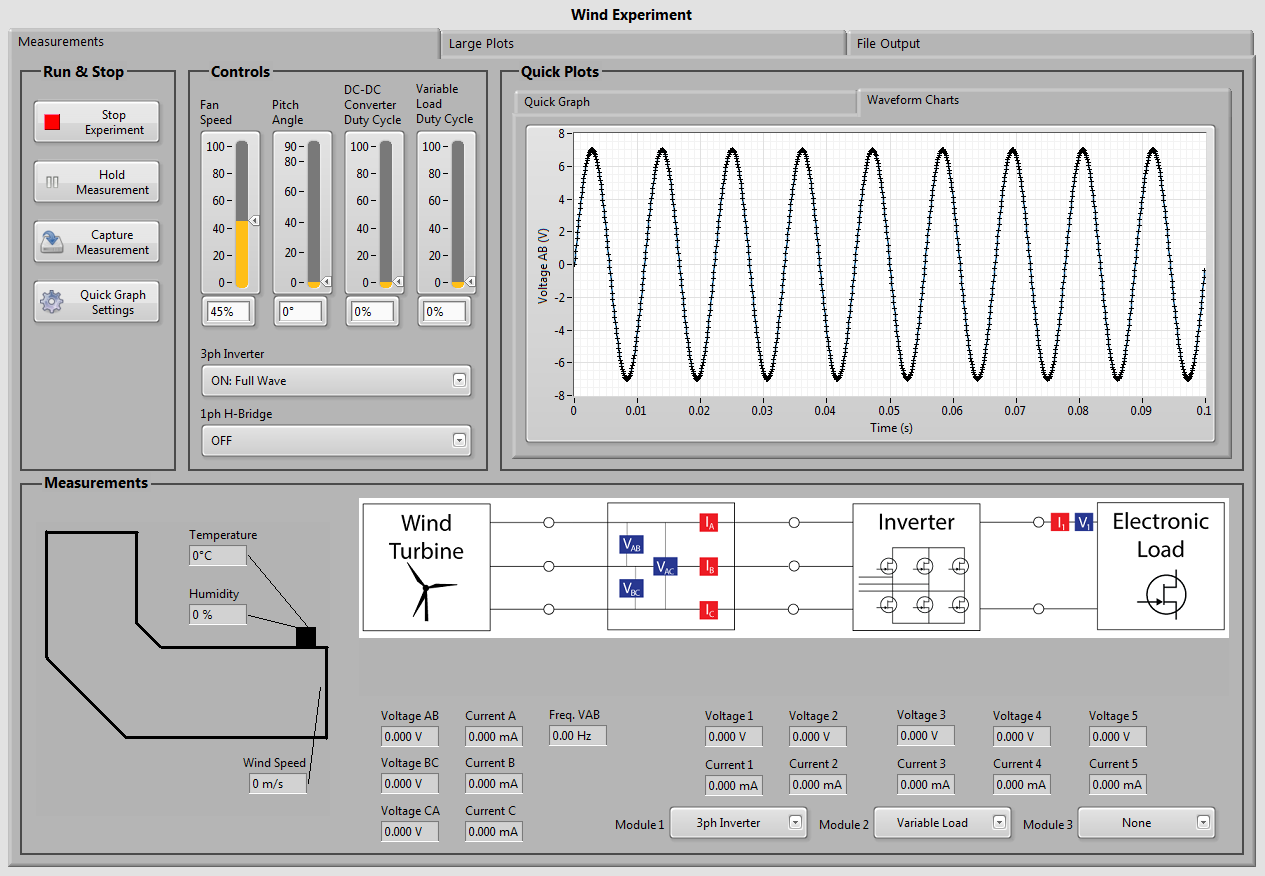

| + | === Experimental Panels === | ||

| + | |||

| + | <p>Experimental panels provide the user with controls for the various parameters of the solar system, wind system and main board. Data acquisition gets data from the sensors and this is displayed real-time on the screen. The “Capture Measurement” button allows users to capture all measurements simultaneously. Waveforms and captured data are displayed in plots for visualisation. File output features allow users to save their captured data to a spreadsheet. Students can then do post processing and generate graphs for reports.</p> | ||

| + | [[File:Experimental_Panel_-_Solar_01.png | frame | centre | x400px | Solar Experimental Panel ]] | ||

| + | [[File:Experimental_Panel_-_Wind_01.png | frame | centre | x400px | Wind Experimental Panel ]] | ||

| + | |||

| + | == Future Work == | ||

| + | The output voltage of the wind turbine is lower as required. Therefore, we need to replace a lower cogging torque wind turbine for the future test and use the DC-DC converter on the main board to improve the output voltage. The wind speed, temperature and humidity sensors need to be recalibrated by using the external microcontroller so as to improve the accuracy. Further functional/operational test on the main PCB should be carried out in the future, especially on the functional/operational test of the DC-DC converter, three phase sensors, inverter and H-bridge. Additionally, the main PCB needs to be improved from the prototype version to correct mistakes such non-plated via hole pads. An informative silk screen with circuit’s representation for students also needs to be developed. The LabVIEW software will also need to be completed, tested and debugged to ensure it is reliable for students. In addition, the integration test needs to be completed so as to examine if the whole system can work together as designed. | ||

| + | |||

| + | Further than this work, it is possible that the system could easily be redeveloped in the future to work completely free of the ELVIS platform, if cost became a concern. | ||

| + | |||

| + | == Team Management == | ||

| + | === Team Members === | ||

| + | * Mr Matthew Schmidt | ||

| + | * Mr Benjamin Young | ||

| + | * Mr Yichen Huo | ||

| + | === Supervisors === | ||

| + | * A/Prof Nesimi Ertugrul | ||

| + | * Dr Hong Gunn Chew | ||

| + | === Team Member Responsibilities === | ||

| + | Group 1 has three members and the responsibilities have been allocated as follows: | ||

| + | *Matt is responsible for the solar experiment, solar external hardware, and solar part of experiment PCB. | ||

| + | *Yichen is responsible for the wind experiment, wind hardware, and the wind part of experiment PCB. | ||

| + | *Ben is responsible for LabVIEW software, plug-in microcontroller PCB and external microcontroller PCBs. | ||

| + | |||

| + | == Resources == | ||

| + | * Power Lab Benches | ||

| + | * ELVIS Board | ||

| + | * Computer | ||

| + | * Oscilloscope | ||

| + | * DC Power Supply | ||

| + | * Signal Generator | ||

| + | * Humidity Meter | ||

| + | * Hot Air Anemometer | ||

Latest revision as of 20:37, 3 June 2015

Contents

Project Overview

Project Motivation

Renewable energy is a fast growing industry. Training systems which are simple to operate, relatively easy to understand and cost effective will be vital in teaching those who move into this industry.

The current Distributed Generation Technologies (DGT) practical can be difficult to set up, and requires at least two multimeters and an oscilloscope to take measurements. It also only uses non-illuminated tests of the solar panel, which are not as accurate as illuminated characteristics. The experiment does not incorporate accurate sensor values to identify the relationship between environmental conditions and the characteristics of the generator. Commercially available options, such as the EMONA HELEX board [1], are very expensive and offer limited functionality. The university is in possession of an ELVIS system that allows for the development of circuit boards that can be directly connected to a 16 channel ADC and other useful digital and analogue outputs and inputs. An improved version of the EMONA board would be a great way to utilise this equipment to improve student learning through practical experience.

Project Introduction

The main aim of this project is to develop an automated education and training tool for wind and solar energy using National Instruments’ ELVIS platform, initially for use in student practicals. The current distributed generation practicals can be difficult to perform, both in wiring correctly and getting accurate measurements. Commercially available alternatives are prohibitively expensive and have limited features.

Using the wind and solar generation systems provided, a plug in board for the NI ELVIS platform was developed. The project started with an assessment of the hardware developed in previous projects, to determine what could be reused or improved. Following this, the new board was developed with a number of circuits which allow the characterisation of both wind and solar generators with load and different power electronic converters. Measurements are automatically carried out by integrated sensors which communicate with LabVIEW via the ELVIS platform, reducing the complexity of generator characterisation.

This project also sought to improve the external sensors utilised to measure environmental conditions. External microcontrollers were added to digitise sensor signals at the source and improve accuracy. Additional humidity and temperature sensors were calibrated for the wind setup. At this point in the project the microcontroller boards have been successfully produced and tested, the main board has been constructed and sensors have been calibrated, and the accompanying LabVIEW software to provide demonstrations has been developed.

Previous Studies

Previous work has been carried out on this project, which will be built upon. Students in previous years have developed the major parts of hardware which we will use for this project. This includes a solar panel system, containing a solar panel with an attached temperature sensor, a controlled light source and stepper motor to tilt the panel. There is also a wind tunnel containing a fan to generate wind, a three phase generator, and temperature and wind sensors.

Objectives of the project

The major aim of this project is to develop a printed circuit board (PCB) to plug into the ELVIS system which can be utilised using LabVIEW software to carry out renewable energy experiments.

This will involve:

• Developing sufficient circuitry to trace basic generator characteristics

• Developing circuitry to demonstrate principles of Maximum Power Point Tracking (MPPT) utilising power electronic converters

• Developing LabVIEW software to control experiments and measure and display values

Hardware

Power System Architecture

As an essential requirement of electronic device, power must be provided in order to support all the internal components function well. Without power all the electronics would not be able to run, hence power is indispensible and the fundamental attributes of all the robots. For this specific autonomous robot system, power source should be portable and powerful enough to supply the main energy consumption from robot’s motion system, as well as supporting all the other components in various situations. When considered about power system design, it could generally be developed into three sessions: overall power system design, selection of power source and detail design of the power circuits.

The diagram above illustrates the architecture of our robot power system. In order to satisfy the mobile and portable requirements of the autonomous robot, we would be using DC battery as the main power source. The battery output connects into a power distribution board, which then separates into multiple channels, for our distribution board we have implemented 5 different channels for future applications.there are only three main channels presented in the diagram.

One channel is designed for the locomotion system only as it's the largest power consumption system of our robot.The gear motor would have the potentials of drawing very high current at stall situations, so we consider the worst condition that if both of the motor is stalling at maximum speed operations, which would draw up to 5Amps current and the distribution board should be able to sustain without causing any damages or instabilities.

The second channel is dedicated for the MyRIO device only, as it's the most important yet vulnerable components of the entire robot system, so we designed it to be isolated from the other channels which would be able to minimize the interferences from other channels, as well as protecting from instantaneous surge current causing by the motors and other components.

The third channel is allocated to the Kinect camera (sensor), since its small voltage range support we have discussed before, even though it's a well integrated module and robust for power variation, it still needs stable power condition to operate properly.

Wind System

The wind system includes the electric fan, fan controller, wind external micro-controller, wind speed sensor, humidity sensors and temperature sensors.

the wind tunnel provides the uniform wind for testing. The electric fan is on top of the wind tunnel. The electric fan is controlled by LabVIEW through external wind micro-controller. The electric fan can provide the wind power to the wind turbine.

Wind Tunnel

A variable pitch propeller and motor set is used for the generator initially. The set used for the test is a 1600KV motor and a 10-inch diameter propeller. It generates power at 1600rpm/V. The wind turbine is controlled by LabVIEW and the three phase AC power signal will be sent to the main board for further test.

The wind power generated by the wind turbine can be calculated from the equation P=1/2 ρAC_p v^3, where P represents the power generated by the wind power; ρ represents the air density; C_p represents the efficiency of the wind turbine; A represents the swept area of blades and v represents the wind speed. Humidity and temperature affect the value of air density. Therefore, wind speed sensor, humidity sensor and temperature sensor are required for the wind system to calculate the efficiency of the wind turbine and take further tests. The wind speed sensor is located at the exit of the wind tunnel, right in front of the wind turbine, to get accurate wind speed near the wind turbine. The temperature and humidity sensor are located on top of the exit of the wind tunnel.

Sensors for Wind System

Experiments using the Board

| Solar |

| Wind |

- Circuits

Microcontroller Boards

Plug-In Microcontroller Board

The purpose of the plug-in microcontroller board is to provide the control signals for the modules on the main board. It was designed as a separate board so that it could be easily interchanged with different microcontroller boards. Also this allowed for easier testing and replacement. The PIC24FV16KM204 was chosen as the microcontroller for the plug-in board. Commands from LabVIEW are sent over SPI.

The plug-in board has sixteen analogue inputs, to sense all the main board voltages and currents. It has ten outputs for controlling the circuits on the main board.

External Microcontroller Board

The purpose of the external microcontroller boards is to perform analogue-to-digital functions on the external sensors (e.g. wind speed sensor), control the external parameters of each system (e.g. solar panel angle). Commands from LabVIEW are sent over SPI. The sensor values are sent back to LabVIEW over SPI. A generic external board was designed, so that it could be used with both the wind and solar system. The PIC18F26K80 was chosen as the microcontroller for the external boards.

The board has five sensor inputs and external pins. Each of these has a ground pin, +5V supply pin and an input signal pin. A +5V voltage reference IC is powered from +15V to provide a reference for analogue-to-digital conversions. The board has an analogue output with a gain that can be set with an on-board operational amplifier. The board also has general purpose input/output pins.

LabVIEW Software

Quiz

A quiz program was developed to be integrated into the main program. It will test students’ knowledge of basic concepts before the experiment.

Experimental Panels

Experimental panels provide the user with controls for the various parameters of the solar system, wind system and main board. Data acquisition gets data from the sensors and this is displayed real-time on the screen. The “Capture Measurement” button allows users to capture all measurements simultaneously. Waveforms and captured data are displayed in plots for visualisation. File output features allow users to save their captured data to a spreadsheet. Students can then do post processing and generate graphs for reports.

Future Work

The output voltage of the wind turbine is lower as required. Therefore, we need to replace a lower cogging torque wind turbine for the future test and use the DC-DC converter on the main board to improve the output voltage. The wind speed, temperature and humidity sensors need to be recalibrated by using the external microcontroller so as to improve the accuracy. Further functional/operational test on the main PCB should be carried out in the future, especially on the functional/operational test of the DC-DC converter, three phase sensors, inverter and H-bridge. Additionally, the main PCB needs to be improved from the prototype version to correct mistakes such non-plated via hole pads. An informative silk screen with circuit’s representation for students also needs to be developed. The LabVIEW software will also need to be completed, tested and debugged to ensure it is reliable for students. In addition, the integration test needs to be completed so as to examine if the whole system can work together as designed.

Further than this work, it is possible that the system could easily be redeveloped in the future to work completely free of the ELVIS platform, if cost became a concern.

Team Management

Team Members

- Mr Matthew Schmidt

- Mr Benjamin Young

- Mr Yichen Huo

Supervisors

- A/Prof Nesimi Ertugrul

- Dr Hong Gunn Chew

Team Member Responsibilities

Group 1 has three members and the responsibilities have been allocated as follows:

- Matt is responsible for the solar experiment, solar external hardware, and solar part of experiment PCB.

- Yichen is responsible for the wind experiment, wind hardware, and the wind part of experiment PCB.

- Ben is responsible for LabVIEW software, plug-in microcontroller PCB and external microcontroller PCBs.

Resources

- Power Lab Benches

- ELVIS Board

- Computer

- Oscilloscope

- DC Power Supply

- Signal Generator

- Humidity Meter

- Hot Air Anemometer