Difference between revisions of "Projects:2018s1-111 IoT Connectivity Investigation"

(→System Overview) |

(→About Ultrasonic Cleaning) |

||

| Line 31: | Line 31: | ||

The operation of Ultrasonic cleaners is not relevant to the rest of this project, except as context for why Soniclean seeks to measure and report the particular parameters on their machines. | The operation of Ultrasonic cleaners is not relevant to the rest of this project, except as context for why Soniclean seeks to measure and report the particular parameters on their machines. | ||

| − | In ultrasonic cleaning, items to be cleaned are placed in a solvent bath of mildly alkaline water. Transducers then blast sound waves through this bath at frequencies above human hearing, hence ultrasonic cleaning. These high frequency, high intensity sound waves cause cavitation- at the trough of the sound wave, there is a region of low pressure, which causes the solution to boil, forming a bubble. As the wave moves on, to it causes this bubble to compress with great force- over 20,000 PSI. This forcefully removes any contaminants from the surface of the objects being cleaned on a microscopic level | + | In ultrasonic cleaning, items to be cleaned are placed in a solvent bath of mildly alkaline water. Transducers then blast sound waves through this bath at frequencies above human hearing, hence ultrasonic cleaning. These high frequency, high intensity sound waves cause cavitation- at the trough of the sound wave, there is a region of low pressure, which causes the solution to boil, forming a bubble. As the wave moves on, to it causes this bubble to compress with great force- over 20,000 PSI. This forcefully removes any contaminants from the surface of the objects being cleaned on a microscopic level.[http://www.soniclean.com.au/uploads/web/20060406-clean_then_sterilise.pdf] |

==System Design == | ==System Design == | ||

Revision as of 18:50, 23 August 2018

Contents

Project Team

Sponsor

Soniclean

Honours Students

Edward Gray

Jack Mansfield

Supervisor

Andrew Allison

Introduction

As computers and network connectivity has become cheaper, more and more devices have been connected to the internet for a wide variety of purposes. These devices which are not used by a human in the way a traditional computer is are known as the "Internet of Things" (IoT.)

This project is sponsored by Soniclean Pty Ltd. "Soniclean® is amongst the world's foremost manufacturers of innovative medical grade ultrasonic cleaners, with over two decades of leadership experience in the ultrasonic industry. Soniclean® ultrasonic cleaners provide a faster, safer alternative to conventional cleaning methods and, using Soniclean's unique Pulse Swept Power® technology, give a superior cleaning performance."[1]

This project seeks to add IoT capability to Soniclean’s ultrasonic cleaning machines to enable new monitoring and auditing functionality. The project aims to develop a system to enable Soniclean's ultrasonic cleaning machines to report their operational status back to a central server. While there are IoT solutions commercially available on the market, Soniclean has determined that they need at least a partially custom solution as they have a unique set of requirements.

Abstract

To meet requirements outlined by Soniclean, we develop a prototype device on top of the existing and widely available Raspberry Pi hardware platform and the MQTT IoT data transmission protocol that will collect data from sensors embedded within Soniclean’s ultrasonic cleaners all over the world and send that data to a central server operated by Soniclean. This will enable Soniclean to offer new auditing and monitoring services for their products and thus grow their business.

We do not implement sensor or back end server systems, that being the responsibility of Soniclean. We only develop a means to collect sensor data and transmit that data back to Soniclean.

Background

About Ultrasonic Cleaning

The operation of Ultrasonic cleaners is not relevant to the rest of this project, except as context for why Soniclean seeks to measure and report the particular parameters on their machines.

In ultrasonic cleaning, items to be cleaned are placed in a solvent bath of mildly alkaline water. Transducers then blast sound waves through this bath at frequencies above human hearing, hence ultrasonic cleaning. These high frequency, high intensity sound waves cause cavitation- at the trough of the sound wave, there is a region of low pressure, which causes the solution to boil, forming a bubble. As the wave moves on, to it causes this bubble to compress with great force- over 20,000 PSI. This forcefully removes any contaminants from the surface of the objects being cleaned on a microscopic level.[2]

System Design

System Overview

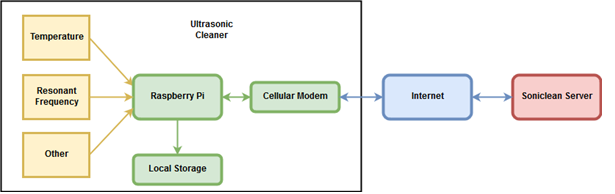

A high level overview of the system is shown below. Sensors (yellow) collect data on the performance of the Ultrasonic cleaner. The compute system (green) collects that data, performs any required processing and saves that data locally. It then sends the data off across the Internet (blue) to the Soniclean server (red.)