Difference between revisions of "Projects:2018s1-175 Split-ring resonators for measuring spatially-distributed complex permittivity at microwave frequencies"

(→BackGround) |

(→Project Design) |

||

| Line 46: | Line 46: | ||

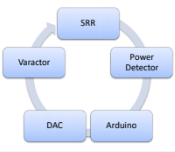

| − | The cycle shows how the overview of the project structure. Starting with SRR as a sensing device to test with different MUT. SRR were | + | The cycle shows how the overview of the project structure. Starting with SRR as a sensing device to test with different MUT. Then, the system continue with the power detector getting the measurement of the power signal produced by the SRR. This power signal then analysed by the arduino board which had been coded to pass the reading of the power signal to the Digital Analog Converter. This reading were then received by the varactor to produce the result of frequency shift made by the SRR. |

== Method == | == Method == | ||

Revision as of 14:13, 18 October 2018

Contents

Introduction

Split Ring Resonator (SRR) is an electromagnetic metamaterial which can be used as a sensing device. This project are developed to produce a 2D permittivity mapping for different types of material under test (MUT). A device which using SRR as a sensing device were produced with a varactor to load the DC voltage replacing VNA and 3 dimension testing of scanning system.

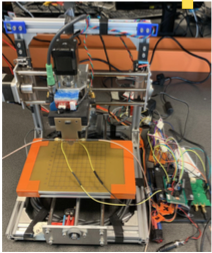

The figure shows how the system that had been build from last year project. This year this project changing the system so that it will be more effective. The varactor had been put into the SRR to replace the VNA and new system which can provide 3D scanning also been added replacing the 2D system made by last year project.

Project Group Members

1. Izatul Natasha Zulkefli

2. Liang Cheng

3. Ziyuan Wang

Project Supervisors

1. Dr. Withawat Withayachumnankul

2. Professor Christophe Fumeaux

Project Aims and Approached

The aims of this project is to make the SRR sensing device produced by the last year group to be give high sensitivity in scanning the MUT.

There is three approached that been explore to increase the sensitivity of the sensing device using SRR.

1. Designing different design of SRR

Designing the SRR is the main part of the project for increasing the sensitivity. This designing process had considered many types of factor so that the SRR can works well when tested with different types of MUT. The shape of SRR had been maintained from the previous shape which is in triangle shape as this shape can give better resolution . As for the design, the microstrip had been change to match with the 50 ohm characteristic impedance for impedance matching with the port. The SRR also were designed with almost no thickness so that it can give better resolution besides can made the varactor being soldiered easily on the SRR. Two inductance line were made to supply dc voltage and stopping the RF signal.

2. Load Varactor on the SRR

Varactor is a diode that can vary its capacitance by loading the dc voltage. This special characteristic made varactor suitable to replaced the VNA . VNA were used by the previous group to produced the resonance shift change when MUT are placed under the SRR. This function were replaced by varactor which vary the dc voltage to get the reading of the frequency shift.

3. 3 Dimension Sensing

The permittivity mapping are done by 2 dimension mapping by last year project. As to increase the permittivity mapping function, a system which allow 3 dimension mapping (x,y and z axis) were produced.

Project Design

The cycle shows how the overview of the project structure. Starting with SRR as a sensing device to test with different MUT. Then, the system continue with the power detector getting the measurement of the power signal produced by the SRR. This power signal then analysed by the arduino board which had been coded to pass the reading of the power signal to the Digital Analog Converter. This reading were then received by the varactor to produce the result of frequency shift made by the SRR.

Method

Increase Resolution of SRR The objective of this method is to develop sensing device which has better resolution by fabricate the SRR more precisely. This can be achieved by using the Ansys HFSS software by designing the SRR in the simulation and after successfully getting result, the SRR will be fabricated. At the end, this SRR can be tested with Interface of LabVIEW, VNA and Microcontroller. There are a few requirement and challenge to do this method. Some requirement to design SRR is 1. Responsive to frequency shift 2.Quality factor increase with practical limits 3.Design must exploit the fringing effect 4.Design must be manufacturable And the challenge to this design is 1. Scanning height and resolution as the height and resolution is inversely proportional relation. 2.Challenge to maintain the size of SRR and the resonant frequency. 3. VNA limit the resonant frequency to 3GHz