Difference between revisions of "Projects:2019s2-20001 Using Machine Learning to Determine Deposit Height and Defects for Wire + Arc Additive Manufacture (3D printing)"

(→Machine Learning) |

|||

| Line 60: | Line 60: | ||

</ul></div> | </ul></div> | ||

=== Machine Learning === | === Machine Learning === | ||

| − | + | Machine learning (or statistical learning) refer to a set of tools to give data scientists an insight into the data and make better decisions based on those information. | |

==== Support Vector Machine ==== | ==== Support Vector Machine ==== | ||

Revision as of 14:32, 6 October 2019

Abstract here

Introduction

3D printing is an emerging technology that has the potential to significantly reduce material usage through the production of near net-shape parts. Many of the systems for 3D printing are based on lasers and powders; however the deposition rate with such systems is very low making the production of large-scale parts difficult. AML Technologies specialises in the use of Wire + Arc Additive Manufacture (WAAM) where deposition is based on arc welding processes and the deposition rates are an order of magnitude greater. When building 3D printed parts, even a relatively small layer height error of only 0.1 mm can produce large build height errors when multiplied across the many layers of a typical build. This can make path planning difficult, so in-process layer height measurement is an essential building block of any production 3D printing system. A variety of techniques can be used for monitoring the layer height including laser scanners, and arc monitoring. It is the latter technique that will be explored in this project due to its robustness, and low cost of implementation – it only requires the measurement of arc current and voltage. Furthermore, it can potentially be used to detect defects by identifying waveform irregularities.

Project team

Project students

- Anh Tran

- Nhat Nguyen

Supervisors

- Dr. Brian Ng

- Dr. Paul Colegrove (AML3D)

Objectives

The objective of this project is to increase the efficiency of the manufacture process at AML3D. In order to do so, the team will investigate into the possibility of automating and optimising the quality control processes. The two quality control processes that are currently being implemented at AML3D are measuring layer height using laser sensors, and human supervision for detecting defects. These processes add overhead into production time and usage of human resource, which is not desired. To achieve the goal, it is expected that machine learning methods will be used extensively to analyse the electrical signatures of the weld process.

Background

Wire Arc Additive Manufacturing

Wire and Arc Additive Manufacturing (WAAM) is a type of additive manufacturing that uses electric arc as the heat source and material wire to feed the manufacture process [1]. WAAM has been investigated since the 1990s [1], but only recently that it received more attention from the manufacture world.

Its significant comes from the ability to manufacture complex model with less time and less material. Figure 1a and 1b show real parts that was manufactured by AML3D. Such custom made parts might takes months before be ready to be shipped, but with WAAM, the production time can reduce down to weeks. Currently, the industries that benefit the most from WAAM are maritime and aerospace.

Similar to other additive manufacture methods, WAAM achieves such results by sliding the models into multiple layers, and then build the model layer by layer. The movement control is normally handled by a robotic arm (AML3D uses ABB's Arc Welder robot), and the welding path is generated by a Computer Aid Manufacture (CAM) software.

Currently at AML3D, the manufacture process for a part can take anywhere from days to weeks. However, the contact tip (where the welding gun deposits the wire) needs replacement every couple of hours. A worn contact tip such as figure 3 will lead to unstable weld and the this effect will propagate and accumulate through multiple layers. Such defects in the manufacture process will no doubt be financially taxing for AML3D. Apart from constant human supervision, another quality control process implemented at AML3D is height measurement of each layer, after the layer is built. This process is implemented to ensure the height of each layer is in the acceptable range (1-2mm). As mentioned before, these quality control processes are costing AML3D in term of time and finance. Our project will focus on replace them with a less time consuming, more automating process.

Gas metal arc welding

-

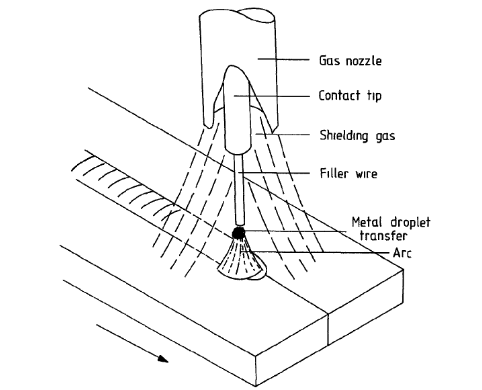

Figure 5: GMAW welding process [2]

Figure 5: GMAW welding process [2]

Gas metal arc welding (GMAW), or also known as metal inert gas (MIG), is the welding process used at AML3D for WAAM. Due to its high deposition rate and economic benefits, GMAW has became more popular. We will explore two variants of GMAW, which are Pulse Multi Control and Cold Metal Transfer. Both processes are developed by Fronius, an Austrian welding company. Note that it is not required to understand the welding physics to follow this wiki. The next two following sections' purpose is to highlight the high variability, high dynamic nature in welding.

Pulse Multi Control

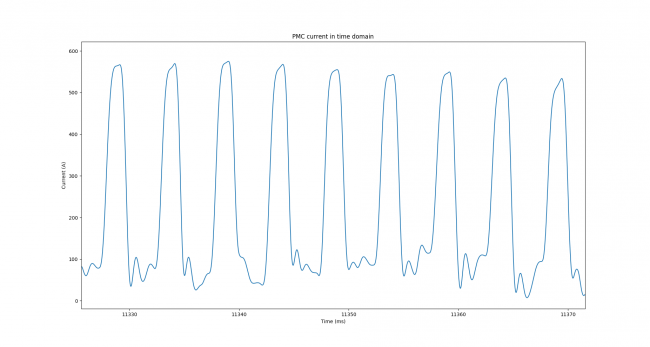

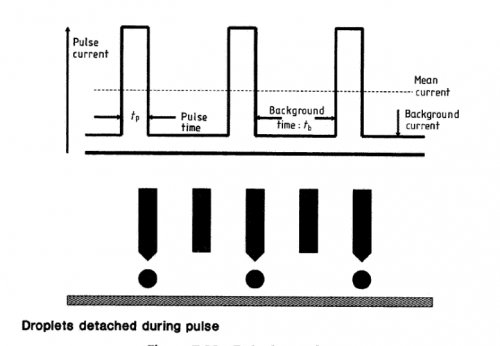

Pulse Multi Control (PMC) welding is Fronius' modified Pulsed GMAW. The advantage of Pulsed GMAW is the ability to control the metal droplet transfer in welding. Note that from figure 7, the metal droplet is characterised by a downward slope of the current pulse. Figure 8 shows the current signal captured from experiments conducted at AML3D (PMC is used).

-

Figure 7: Relationship between pulse current and droplet transfer[2]

Figure 7: Relationship between pulse current and droplet transfer[2]

Cold Metal Transfer

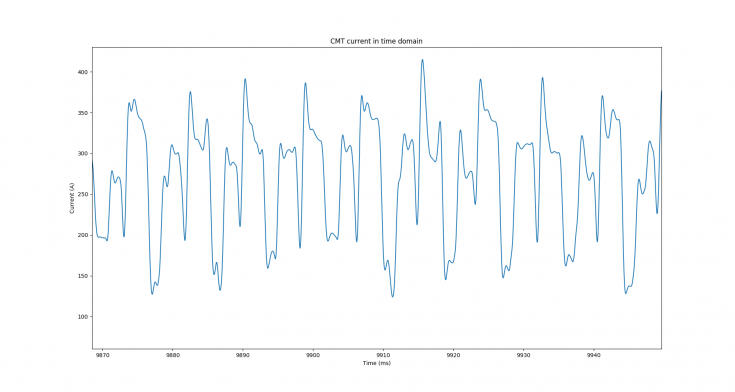

Cold Metal Transfer (CMT) is a complex welding process, also developed by Fronius. By detecting a short circuit (mode C and D in figure 9), CMT can make adjustment such as retracting the welding material to cool down, and therefore create a smoother, more stable weld. The complexity of CMT can be seen in the current signal of the process (figure 10). Compare to PMC, CMT's signal has more variation during one signal period.

Machine Learning

Machine learning (or statistical learning) refer to a set of tools to give data scientists an insight into the data and make better decisions based on those information.