Difference between revisions of "Projects:2014S1-01 Development of Fully Automated Educational and Training Tool for Wind and Solar Energy using National Instruments’ ELVIS Based System"

(→System Architecture) |

|||

| Line 17: | Line 17: | ||

[[File:Bigger-Block-Diagram(2).png| 700px]] | [[File:Bigger-Block-Diagram(2).png| 700px]] | ||

| − | |||

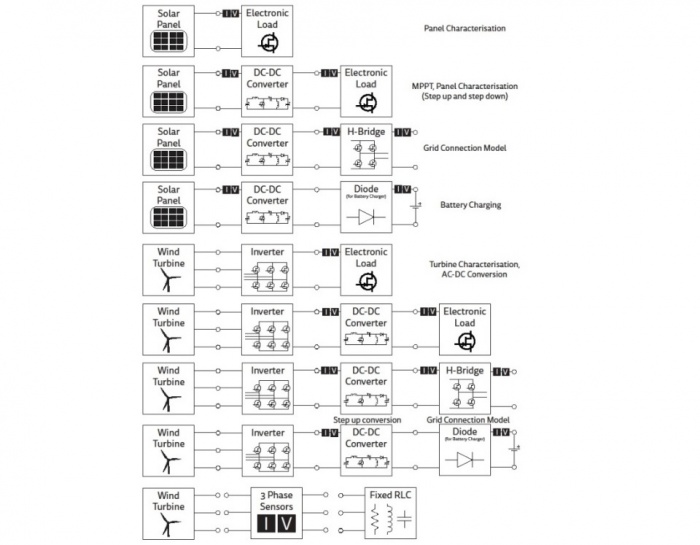

=== Functional Block Diagram of the Wind and Solar System === | === Functional Block Diagram of the Wind and Solar System === | ||

[[File:mosfetLoad.png | frame | left | 150px | This provides a variable resistance or constant voltage load for testing. ]] | [[File:mosfetLoad.png | frame | left | 150px | This provides a variable resistance or constant voltage load for testing. ]] | ||

Revision as of 16:10, 26 October 2014

Contents

Project Information

Project Introduction

The main aim of this project is to develop an automated education and training tool for wind and solar energy using National Instruments’ ELVIS platform, initially for use in student practicals. The current distributed generation practicals can be difficult to perform, both in wiring correctly and getting accurate measurements. Commercially available alternatives are prohibitively expensive and have limited features.

Using the wind and solar generation systems provided, a plug in board for the NI ELVIS platform was developed. The project started with an assessment of the hardware developed in previous projects, to determine what could be reused or improved. Following this, the new board was developed with a number of circuits which allow the characterisation of both wind and solar generators with load and different power electronic converters. Measurements are automatically carried out by integrated sensors which communicate with LabVIEW via the ELVIS platform, reducing the complexity of generator characterisation.

This project also sought to improve the external sensors utilised to measure environmental conditions. External microcontrollers were added to digitise sensor signals at the source and improve accuracy. Additional humidity and temperature sensors were calibrated for the wind setup. At this point in the project the microcontroller boards have been successfully produced and tested, the main board has been constructed and sensors have been calibrated, and the accompanying LabVIEW software to provide demonstrations has been developed.

System Architecture

The Solar External Hardware block includes: a PV panel; a stepper motor; a lamp box; sensors; and the mechanical structure that holds these components together. The stepper motor controls the angle of the PV panel. The lamp box will simulate the sun and consists of down lights, down light transformers and a dimmer. Sensors include a temperature sensor and a light intensity sensor.

The Wind External Hardware block includes: a wind tunnel; wind turbine and generator; and sensors. The generator is a hobby BLDC motor. The sensors include wind speed, temperature and humidity sensors.

One main PCB and several sub PCBs will be designed and constructed in this project. The main PCB will provide circuitry and data acquisition capability required to find the characteristics of the PV panel and the wind turbine. Two fixed load PCBs will provide a platform of the RL and RC tests for the wind system. A microcontroller PCB will control the buck/boost converter, 3 phase inverter and 1 phase H-bridge inverter. External microcontroller PCBs will also control and receive data from the wind speed sensor, temperature sensors and the humidity sensor.

The desktop computer will run an educational LabVIEW program that will be developed in this project. The LabVIEW program will guide students through experiments, and allow students to control on-board and external hardware, take measurements from on-board and external sensors, and analyse those measurements.

Functional Block Diagram of the Wind and Solar System

Team Management

Team Members

- Mr Matthew Schmidt

- Mr Benjamin Young

- Mr Yichen Huo

Supervisors

- A/Prof Nesimi Ertugrul

- Dr Hong Gunn Chew

Team Member Responsibilities

Group 1 has three members and the responsibilities have been allocated as follows:

- Matt is responsible for the solar experiment, solar external hardware, and solar part of experiment PCB.

- Yichen is responsible for the wind experiment, wind hardware, and the wind part of experiment PCB.

- Ben is responsible for the LabVIEW software and the motherboard PCB.

Resources

- Power Lab Benches

- ELVIS Board

- Computer

- Oscilloscope

- DC Power Supply

- Signal Generator

- Humidity Meter

- Hot Air Anemometer