Difference between revisions of "Projects:2015s2-206 Solar Aquaponics"

(→Energy) |

(→Subsystem & Simulation) |

||

| Line 52: | Line 52: | ||

The solar system simulates the total electricity generated and the consumed within aquaponics system by pumps, lights, heaters, fans etc. The energy balance in between is the floating energy which is chosen as a stock. The floating energy is various and floating within a certain range; the power generated by solar modules is of the same shape with solar irradiant; the electricity consumed by aquaponics system is fairly constant when the system scale is defined. | The solar system simulates the total electricity generated and the consumed within aquaponics system by pumps, lights, heaters, fans etc. The energy balance in between is the floating energy which is chosen as a stock. The floating energy is various and floating within a certain range; the power generated by solar modules is of the same shape with solar irradiant; the electricity consumed by aquaponics system is fairly constant when the system scale is defined. | ||

| − | [[File:Energy simulation.png | | + | [[File:Energy simulation.png | 600px | thumb | center | Solar Energy Simulation]] |

=='''Use of Model'''== | =='''Use of Model'''== | ||

Revision as of 22:07, 28 May 2016

Contents

Project Team

Supervisors

Dr Rastko Zivanovic

Dr Said Al-Sarawi

Group Members

Haokun Wang

Mengna Xu

Project Introduction

Background

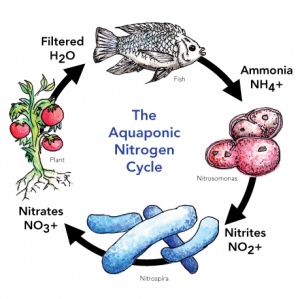

Aquaponics combines aquaculture and hydroponics, which integrates raising fish and growing plants in one symbiotic system, where water in fish tanks that is rich in nutrients is used for plant growth. As an promising food production system, Recirculating Aquaculture Systems(RAS) has experienced rapid development in Europe and US in the early 20th and it’s gaining popularity within Australia where drought has making it very appealing as it uses 90 percent less water than conventional cultivation method(Diver, 2000). RAS provides better opportunity for recirculating water and management of waste processing and nutrient recycling. The key to success of aquaponics system relies on the symbiosis of fish, microorganisms and plants. Plants and fish species and ratio, hydroponic effluent water flow rate, solid removal efficiency (mechanical filter performance), nitrification efficiency (bio-filter performance), daily feed to fish, food conversion ratio (FCR), water and medium environment etc. are all of key concerns in establishing a complete aquaponics system.

Motivation

Besides human labor, energy consumption can be the largest cost factor in RAS. The electricity consumption mainly comes from water pumps and air pumps running continuously or periodically for circulating water and aeration; resistive heaters to maintain water temperature for fish during winter; growing light for grow beds; infrastructure facilities such as box fans and computers for data monitoring. The energy consumption can be huge in commercial aquaponics. The project investigated a practical way of solar system design and energy supply to a scalable aquaponics system aims at optimising the conventional power supply by power grid.

Project Scope

Our project dedicating in investigation of solar energy supply in aquaponics system instead of connecting to conventional power grid. Power input and consumption in system, water circulation within RAS, fish and plants growing dynamics and nitrification cycle are modelled and monitored by AnyLogic stock and flow diagram and are integrated within one dynamic system. pH sensor for water, ammonia sensor for growing medium and pyranometer for solar radiation measurement are applied in the real model. Data are recorded through wireless link to devices.

The project consists of two major stages: establishing aquaponics system modelled by AnyLogic; and building a practical media-based aquaponics system. The software system is divided into 5 major subsystems: Solar energy; Water circulation; Fish raising; Plant growing and Nitric-cycle (Nitrification Process); Major components toward system production and environment indicators are monitored by model with changeable system input (planting area and system water volume). The second stage is implementation of a practical model with solar energy supply. A media-based system with 22L water volume and 0.1m2 is built for 5 gold fish and bean sprouts. pH and ammonia level are monitored via sensors as verifications of system well being and function.

Software Development & Model Simulation

Mainboard Design

The aquaponics system together with solar supply consists of five subsystems: fish, plants, water cycle, nitric and energy. Key parameters such as daily fish feed, daily water assumption and pump power act as correlations between each subsystem. (See Figure 2.) Fish feeding to recirculating aquaponics system (RAS) and daily adding water are two major system input to aquaponics system. The fish feed and system water volume influence the concentration of TAN (total ammonia of nitrogen) and nitrate nitrogen, which is essential for plants growth. The system input parameters are system water volume (L) and planting area (m2), the system can be further enriched with other fish/plants species and feed type.

Subsystem & Simulation

Energy

The solar system simulates the total electricity generated and the consumed within aquaponics system by pumps, lights, heaters, fans etc. The energy balance in between is the floating energy which is chosen as a stock. The floating energy is various and floating within a certain range; the power generated by solar modules is of the same shape with solar irradiant; the electricity consumed by aquaponics system is fairly constant when the system scale is defined.

Use of Model

System Implementation

System Construction

Plant & Fish

Test & Monitoring

Conclusion

Reference

Amoah, Y. T., Thorarensen, H., & Sigurgeirrson, M. O. EFFECT OF DIETARY PROTEIN LEVELS ON GROWTH AND PROTEIN UTILIZATION IN JUVENILE ARCTIC CHAR (Salvelinus alpinus).

Bailey, D. S., Rakocy, J. E., Cole, W. M., Shultz, K. A., & St Croix, U. (1997). Economic analysis of a commercial-scale aquaponic system for the production of tilapia and lettuce. Paper presented at the Tilapia Aquaculture: Proceedings of the Fourth International Symposium on Tilapia in Aquaculture, Orlando, Florida.

Buzby, K. M., & Lin, L.-S. (2014). Scaling aquaponic systems: Balancing plant uptake with fish output. Aquacultural Engineering, 63, 39-44. doi:http://dx.doi.org/10.1016/j.aquaeng.2014.09.002 Chalmers, G. A. (2004). ″Aquaponics and Food Safety ″. Lethbridge, Alberta April.

Chowdhury, D. K. (2011). Optimal feeding rate for Nile tilapia (Oreochromis niloticus).

Diver, S. (2000). Aquaponics-Integration of hydroponics with aquaculture: Attra.

Endut, A., Jusoh, A., & Ali, N. a. (2014). Nitrogen budget and effluent nitrogen components in aquaponics recirculation system. Desalination and Water Treatment, 52(4-6), 744-752.

Fox, B. K., Howerton, R., & Tamaru, C. S. (2010). Construction of automatic bell siphons for backyard aquaponic systems: [Cooperative Extension Service], College of Tropical Agriculture and Human Resources, University of Hawaiʻi at Mānoa.

Goddek, S., Delaide, B., Mankasingh, U., Ragnarsdottir, K. V., Jijakli, H., & Thorarinsdottir, R. (2015). Challenges of sustainable and commercial aquaponics. Sustainability, 7(4), 4199-4224.

Howell, J. R., Bannerot, R. B., & Vliet, G. C. (1982). Solar-thermal energy systems: analysis and design: Mcgraw-Hill College.

Love, D. C., Uhl, M. S., & Genello, L. (2015). Energy and water use of a small-scale raft aquaponics system in Baltimore, Maryland, United States. Aquacultural Engineering, 68, 19-27. doi:http://dx.doi.org/10.1016/j.aquaeng.2015.07.003

Martins, C. I. M., Eding, E. H., Verdegem, M. C. J., Heinsbroek, L. T. N., Schneider, O., Blancheton, J. P., . . . Verreth, J. A. J. (2010). New developments in recirculating aquaculture systems in Europe: A perspective on environmental sustainability. Aquacultural Engineering, 43(3), 83-93. doi:http://dx.doi.org/10.1016/j.aquaeng.2010.09.002

Masser, M. P., Rakocy, J., & Losordo, T. M. (1999). Recirculating aquaculture tank production systems. Management of recirculating systems. SRAC Publication, 452.

Morrison, G. L., & Litvak, A. Condensed solar radiation data base for Australia.

MOSS, J., CORAM, A., & BLASHKI, G. (2014). SOLAR ENERGY IN AUSTRALIA.

Nelson, R. L. (2008). Aquaponic Equipment The Bio Filter.

Ng, W.-k., Lu, K.-S., Hashim, R., & Ali, A. (2000). Effects of feeding rate on growth, feed utilizationand body composition of a tropical bagrid catfish. Aquaculture International, 8(1), 19-29.

Nunez, M. (1990). Solar energy statistics for Australian capital regions. Solar Energy, 44(6), 343-354. doi:http://dx.doi.org/10.1016/0038-092X(90)90138-3

Rakocy, J. E., Bailey, D. S., Shultz, R. C., & Danaher, J. J. (2011). A commercial-scale aquaponic system developed at the University of the Virgin Islands. Paper presented at the Proceedings of the 9th International Symposium on Tilapia in Aquaculture.

Rakocy, J. E., Bailey, D. S., Shultz, R. C., & Thoman, E. S. (2004). Update on tilapia and vegetable production in the UVI aquaponic system. Paper presented at the New Dimensions on Farmed Tilapia: Proceedings of the Sixth International Symposium on Tilapia in Aquaculture, Held September.

Rakocy, J. E., & Brunson, M. W. (1989). Tank culture of tilapia: Southern Regional Aquaculture Center College Station, Texas.

Riche, M., & Garling, D. (2003). Feeding tilapia in intensive recirculating systems.

Soong, W. (2008). Renewable Electric Energy Systems: Solar and Wind Principles. School of Electrical and Electronic Engineering University of Adelaide, Australia.

Timmons, D., Michael, B., & Goldstein, L. T. (2014). Quantification of root nitrification capacity of bibb lettuce plants for use in a recirculating aquaculture system (RAS).