Difference between revisions of "Projects:2015s2-206 Solar Aquaponics"

(→Reference) |

(→Practical Ratio) |

||

| Line 76: | Line 76: | ||

=='''Use of Model'''== | =='''Use of Model'''== | ||

==='''Practical Ratio'''=== | ==='''Practical Ratio'''=== | ||

| − | The ratio for planting area and system water volume are roughly 1/ | + | The ratio for planting area and system water volume are roughly 1/145, based on studies of University of Virgin Island commercial aquaponics (with 214 m2 planting area and 31200L fish tank volume). A practical sizing calculator developed by Dr Wilson Lennard is used as reference in the model. [http://www.aquaponic.com.au/calculators.htm] When changing the input parameter based on the ratio, the fish and plants output (kg), daily water consumption (L) and energy consumption are changing proportionally. The TAN and nitrate nitrogen concentration are roughly the same. |

==='''Significance & Verification'''=== | ==='''Significance & Verification'''=== | ||

Revision as of 19:55, 30 May 2016

Contents

Project Team

Supervisors

Dr Rastko Zivanovic

Dr Said Al-Sarawi

Group Members

Haokun Wang

Mengna Xu

Project Introduction

Background

Aquaponics combines aquaculture and hydroponics, which integrates raising fish and growing plants in one symbiotic system, where water in fish tanks that is rich in nutrients is used for plant growth. As an promising food production system, Recirculating Aquaculture Systems(RAS) has experienced rapid development in Europe and US in the early 20th and it’s gaining popularity within Australia where drought has making it very appealing as it uses 90 percent less water than conventional cultivation method(Diver, 2000). RAS provides better opportunity for recirculating water and management of waste processing and nutrient recycling. The key to success of aquaponics system relies on the symbiosis of fish, microorganisms and plants. Plants and fish species and ratio, hydroponic effluent water flow rate, solid removal efficiency (mechanical filter performance), nitrification efficiency (bio-filter performance), daily feed to fish, food conversion ratio (FCR), water and medium environment etc. are all of key concerns in establishing a complete aquaponics system.

Motivation

Besides human labor, energy consumption can be the largest cost factor in RAS. The electricity consumption mainly comes from water pumps and air pumps running continuously or periodically for circulating water and aeration; resistive heaters to maintain water temperature for fish during winter; growing light for grow beds; infrastructure facilities such as box fans and computers for data monitoring. The energy consumption can be huge in commercial aquaponics. The project investigated a practical way of solar system design and energy supply to a scalable aquaponics system aims at optimising the conventional power supply by power grid.

Project Scope

Our project dedicating in investigation of solar energy supply in aquaponics system instead of connecting to conventional power grid. Power input and consumption in system, water circulation within RAS, fish and plants growing dynamics and nitrification cycle are modelled and monitored by AnyLogic stock and flow diagram and are integrated within one dynamic system. pH sensor for water, ammonia sensor for growing medium and pyranometer for solar radiation measurement are applied in the real model. Data are recorded through wireless link to devices.

The project consists of two major stages: establishing aquaponics system modelled by AnyLogic; and building a practical media-based aquaponics system. The software system is divided into 5 major subsystems: Solar energy; Water circulation; Fish raising; Plant growing and Nitric-cycle (Nitrification Process); Major components toward system production and environment indicators are monitored by model with changeable system input (planting area and system water volume). The second stage is implementation of a practical model with solar energy supply. A media-based system with 22L water volume and 0.1m2 is built for 5 gold fish and bean sprouts. pH and ammonia level are monitored via sensors as verifications of system well being and function.

Software Development & Model Simulation

Mainboard Design

The aquaponics system together with solar supply consists of five subsystems: fish, plants, water cycle, nitric and energy. Key parameters such as daily fish feed, daily water assumption and pump power act as correlations between each subsystem. (See Figure 2.) Fish feeding to recirculating aquaponics system (RAS) and daily adding water are two major system input to aquaponics system. The fish feed and system water volume influence the concentration of TAN (total ammonia of nitrogen) and nitrate nitrogen, which is essential for plants growth. The system input parameters are system water volume (L) and planting area (m2), the system can be further enriched with other fish/plants species and feed type.

Subsystem & Simulation

Energy

The solar system simulates the total electricity generated and the consumed within aquaponics system by pumps, lights, heaters, fans etc. The energy balance in between is the floating energy which is chosen as a stock. The floating energy is various and floating within a certain range; the power generated by solar modules is of the same shape with solar irradiant; the electricity consumed by aquaponics system is fairly constant when the system scale is defined.

Fish

Fish in aquaponics system will produce fish waste, which will be pumped into bio-filter and plant growing bed with water. The amount of waste product will affect the nutrient assimilation and hence the plant biomass and harvest weight. The waste product acts as the connection bridge between fish system and nitric-cycle system. To simplify the nutrient cycling, we consider the major component in fish waste product, that’s Total Ammonia of Nitrogen, or TAN(Martins et al., 2010). It’s affected by the daily feed to RAS (usually 1%~3% of fish current weight) and protein amount in fish feed (usually 20%~30%).

The model simulates the dynamic weight change in RAS, with certain amount of fingerling input and fish harvest each month. The weight of fish input and output and RAS shall be in dynamic balance as long as the system is operating. The TAN and RAS curves shall be saw tooth curve floating among a certain weight range. The curve for fish input and output are idealised to be pulse curve which happens every 30 days.

Plants

The model is designed to reflect the plant weight change in growing bed and plant harvest weight under the influence of nitrate concentration from nitric cycle; also, the curve for daily adding water will reflect as water consumption will affect the water circulating system. The water needs to be adding daily mainly due to evaporation and water leakage when circulating. The relationship between nitrate concentration and plant growth are fairly complicated, as there are no scientific formulas to describe this

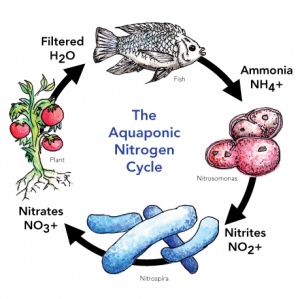

Nitric Cycle

We connect the fish part and nitric cycle part with daily feed to RAS as it is the only source of nitrogen atom in the cycle. The total nitrogen converts to nitrate () are influenced by four factors: the daily feed to RAS, feed utilisation, feed becoming TAN and feed protein level. The output nitrate () are assumed all taken up by the plants. The nitrate concentration (mg/L) is monitored by plot curve as indicator of biofilter performance.

Water Circulation

The circulation of water in fish tank and planting bed remain constant in an idealized condition. The daily adding water influence the input and output water in the system.

Use of Model

Practical Ratio

The ratio for planting area and system water volume are roughly 1/145, based on studies of University of Virgin Island commercial aquaponics (with 214 m2 planting area and 31200L fish tank volume). A practical sizing calculator developed by Dr Wilson Lennard is used as reference in the model. [1] When changing the input parameter based on the ratio, the fish and plants output (kg), daily water consumption (L) and energy consumption are changing proportionally. The TAN and nitrate nitrogen concentration are roughly the same.

Significance & Verification

Verification of model

The model reflects the dynamic changes of aqua-farming processes as well as energy consumption. Various system input shows system performance under different scales. The system output such as battery energy indicates the energy storage capacity. The concentration of TAN and nitrate nitrogen can be used to find out the optimum planting ratio. Different ratio of planting area and water volume results to the value change of system outputs. Example for battery energy and fish weight in RAS are given in figure 8. Stable ratio of planting area and water volume results to proportional change of system outputs, verified the stability of model.

UVI Verification

Compared with TAN concentration level and nitrate nitrogen (𝑁𝑂3−) level with studies from UVI system, obtained similar trend and value.

System Implementation

The model has a grow bed of 4 gallons of media (with expanded clay pebbles) and a fish tank of 8.1 gallons. Green bean sprouts and garlic are cultivated as well as 5 gold fish in the tank. The system is monitored with pH and ammonia sensors as well as testing kit. A 12V DC pump is the only load in the system powered by solar panel and backup battery. The pump is activated 5 minutes, 10 times daily with a programmable timer. The bell siphon in the grow bed enables automatic flood and drain processes periodically which ensures the efficient removal of fish waste and continuity of nutrient recycle. To ensure the safety of fish and make the system more reliable for food production, we added a mechanical filter to help remove the solid waste in cycling water with changeable wool and sponge. The materials for construction mainly obtained from IKEA SA and local aquarium shop (Seaview Aquarium Centre); the equipment for solar design comes from Jaycar Electronics and eBay online.

System Construction

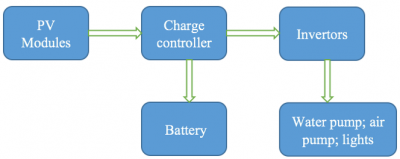

Solar System

The solar panels are connected to charge controller to prevent reverse current and overcharge of battery banks. The battery banks balance the power generated by panel and function as power source during cloudy days and nights. In larger scale aquaponics system with AC loads such as heaters or lights needs inverter to convert DC power to AC, it will also act as a switch to protect battery from over discharging. A timer for flood and drain system is attached to the inverter for controlling the running hours for pumps. Our small home yard system is a 12V DC system with battery backup power. We included a 12V 3W brushless DC pump as the only load for the initial stage of system. The solar system in our aquaponics system consists of 10W solar panel, 12V charge controller, 12Ah backup battery and 12V 3W brushless DC pump with a timer. The timer controls the switch of pump to ensure proper water influent to grow bed which matches the bell siphon’s performance. The solar panel is oriented to the true north, fixed to a stand (made in workshop) with a changeable tilting angle.

Aquaponics System

The fish tank has a dimension of 39*28*28(cm) which can hold 22L of water. The media bed has a dimension of 39*28*14(cm) with planting area of 0.11m2 and media volume of 4.03 gallon (Figure 12). We establish our system scale according to general experience of aqua-farming: approximately 1-2 of growing area matches for 10 gallons of fish tank water (Chalmers, 2004).

Test & Monitoring

pH

The pH is decreasing from 7.18 to 7.11 during 4-day monitor. The pH in fish tank decreases daily due to acid produced during nitrification processes. The optimal pH for gold fish is 7.2. In practical, calcium and potassium hydroxide are added several times a week to maintain pH level constant in aquaponics system (Rakocy et al., 2011). The monitor of pH can keep us informed of the living environment of fish and conduct water treatment accordingly.

Ammonia

We collected data for ammonia concentration in fish tank with and without hydroponics treatment. With hydroponics treatment, the ammonia level floats between 0.8 mg/L and 1.2 mg/L, up to 38% more ammonia removal than without hydroponics tank, which the ammonia level increases from 1.25 mg/L to 1.45 mg/L during the experiment. The results indicate a good ammonia removal ability by aquaponics system and an efficient control to keep ammonia concentration within acceptable range.

Conclusion

During the two major stages: software model and system implementation, the major functions of the model is basically achieved. The model is scalable with different ratios of input (water volume and planting area) with reasonable output parameter. The results from modelling of UVI commercial aquaponics shown similar results from previous studies: with nutrient concentration level revolving around reasonable range and similar curve trends. With stocking density of 77 fish/m3, the ammonia level revolving around 1.39--2.02 mg/L; the nitrate nitrogen level fluctuates between 45.25--55.92mg/L; the RAS stocking fish changes proportionally with initial size of planting bed and water volume. The pH and ammonia concentration monitored via sensor shows the waste removal ability of aquaponics system with up to 38% less ammonia concentration. Operating small aquaponics system can be an excellent hobby. The system can be as small as an aquarium with a tray of plants covering the top.Aquaponics is ideal for areas with limited resources such as land and water. The system is highly productive with intensive use of system input (fish feed, water and microelement supplement). The removal of nutrients by plants prolongs water use and minimize discharge. Aquaponics system requires less monitoring for water quality than conventional hydroponics or aquaculture production, and usually have a wider safety margin for ensuring good water quality.

Reference

[1]C. David, P. Jillian, G. Laura, S. Elizabeth, S. J. Adam, L. Ximin, S. Ken, “An International Survey of Aquaponics Practitioners,” PLOS ONE, vol. 9, no. 7, pp. 1-10, 2014.

[2] C. David, P. F. Jillian, L. Ximin, S. H. Elizabeth, G. Laura, S. Ken, E. T. Richard, “Commercial aquaponics production and profitability: Findings from an international survey,” Aquaculture, vol. 435, pp. 67–74, 2015 aquaponic system,” Bioresource Technology, vol. 101, pp. 1511–1517, 2010.

[3] C. David, S. U. Michael, G. Laura, “Energy and water use of a small-scale raft aquaponics system in Baltimore, Maryland, United States,” Aquacultural Engineering , vol. 68, pp. 19–27, 2015.[4] G. Andreas, J. Ranka, “Aquaponic Systems: Nutrient recycling from fish wastewater by vegetable production,” Desalination, vol. 246, pp. 147-156, 2009.

[5] E. Aziza, A. Jusoh, N. Ali, W.B. Wan Nik, A. Hassan, “A study on the optimal hydraulic loading rate and plant ratios in recirculation

[6] G. Simon, D. Boris, M. Utra, V. R. Kristin, J. Haissam and T. Ragnheidur, “Challenges of Sustainable and Commercial Aquaponics,” sustainability, pp. 4199–4224, 2015.

[7] M. B. Karen, L. Lian-Shin, “Scaling aquaponic systems: Balancing plant uptake with fish output,” Aquacultural Engineering , vol. 63, pp. 39-44, 2014.

[8] S. Klein, E. Rubin, “Life cycle assessment of greenhouse gas emissions, water and land use for concentrated solar power plants with differentenergy backup systems,” Energy Policy, vol. 63, pp. 935-950, 2013.

[9] T. L. Matthew, V. Vilayanur, R. S. Venkat, “Balancing autonomy and utilization of solar power and battery storage for demand based microgrids,” Journal of Power Sources, vol. 279, pp. 645-655, 2015.

[10]Amoah, Y. T., Thorarensen, H., & Sigurgeirrson, M. O. EFFECT OF DIETARY PROTEIN LEVELS ON GROWTH AND PROTEIN UTILIZATION IN JUVENILE ARCTIC CHAR (Salvelinus alpinus).

[11]Bailey, D. S., Rakocy, J. E., Cole, W. M., Shultz, K. A., & St Croix, U. (1997). Economic analysis of a commercial-scale aquaponic system for the production of tilapia and lettuce. Paper presented at the Tilapia Aquaculture: Proceedings of the Fourth International Symposium on Tilapia in Aquaculture, Orlando, Florida.

[12]Buzby, K. M., & Lin, L.-S. (2014). Scaling aquaponic systems: Balancing plant uptake with fish output. Aquacultural Engineering, 63, 39-44. doi:http://dx.doi.org/10.1016/j.aquaeng.2014.09.002 Chalmers, G. A. (2004). ″Aquaponics and Food Safety ″. Lethbridge, Alberta April.

[13]Chowdhury, D. K. (2011). Optimal feeding rate for Nile tilapia (Oreochromis niloticus).

[14]Diver, S. (2000). Aquaponics-Integration of hydroponics with aquaculture: Attra.

[15]Endut, A., Jusoh, A., & Ali, N. a. (2014). Nitrogen budget and effluent nitrogen components in aquaponics recirculation system. Desalination and Water Treatment, 52(4-6), 744-752.

[16]Fox, B. K., Howerton, R., & Tamaru, C. S. (2010). Construction of automatic bell siphons for backyard aquaponic systems: [Cooperative Extension Service], College of Tropical Agriculture and Human Resources, University of Hawaiʻi at Mānoa.