Projects:2015s1-72 Wind Turbine Control Simulator

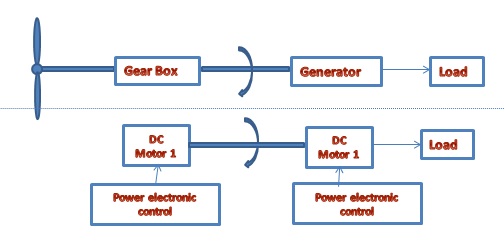

This project aims to build a wind turbine simulator consisting of two small DC machines coupled together and the associated power electronics and control circuitry. The first DC machine acts a motor which produces an output torque versus speed characteristic which simulates the mechanical output of a wind turbine. For a fixed wind speed, under no-load conditions the DC motor will operate at the no-load speed of the wind turbine it is simulating. As the load torque on the wind turbine is increased, the DC motor reduces its speed until it reaches the turbine stall torque at zero speed. The second DC machine acts a generator which simulates the electric generator connected to a wind turbine. This generator is controlled to try to maximize the electrical power output for a given wind speed.

Contents

Supervisors

Wen Soong

Nesimi Ertugrul

Group Members

Bingyang Lu

Hui Zhou

Yubo Xiu

Project scope

The wind turbine simulator project includes design, simulating, constructing and testing of a wind turbine power generation simulation system. The system is constructed by two parts, a wind turbine simulator and a maximum power point tracking system. Each part consists of a DC motor and some power electronic controllers.

Figure 1-1. System scope overview

The first DC motor will act as a fixed pitch control wind turbine. It would produce the same torque versus rotation speed characteristic under a specific or varies wind speed. This motor will be controlled by a Matlab based wind turbine model. The second DC motor acts as the generator of the wind power system. Some maximum power tracking algorithms will also be applied to this motor by Matlab.

Background

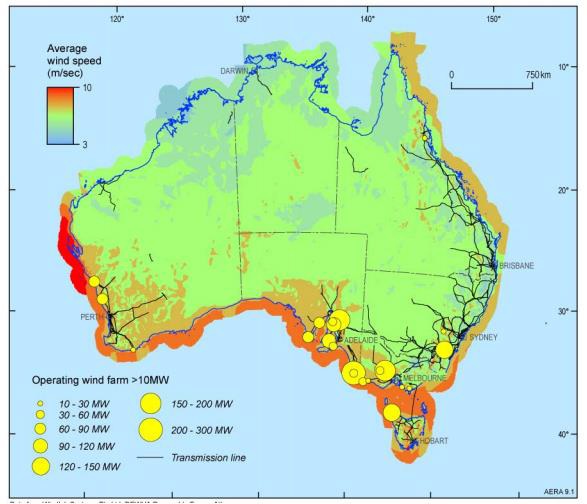

The wind market has developed rapidly these years. A new report from Navigant Research covers developments in the wind energy sector during 2014, including an analysis of the important changes in the industry over the last three years and global market forecasts through 2019. It says that fueled by the policy-driven acceleration of installations in three key countries—China, Germany and United States,--the global wind industry staged a remarkable comeback in 2014. Wind power is predicted to provide 5% of the world‘s energy in 2020. In Australian, the southern coastline lies in the roaring forties and hundreds of sites have average wind speed above eight and even night m/s at 50m above ground. Nowadays, there are 68 wind farm of greater than 100kw capacity operating in Australian. The biggest wind farm is in Victoria Macarthur wind farm, which has capacity of 420MW. Also, the government of Australia is aiming to produce 20% entire electricity supply from renewable energy sources by 2020.

Figure 1-2 Australian wind resource

Motivation

One of the most significant motivations of this project is the increasing demand of laboratory purpose wind turbine simulators. Wind energy had a fast development for the last two decades because of its cleanness. Wind energy is one of the renewable fuel which make it possible to control he energy injected into the network and to produce not polluting fuel usable in the buildings and thus to diversity the energy markets. Due to wide applications and limited economic constraints, the conversion chain of this energy must be robust and reliable. Also, a better efficiency and be realized at low cost are pursued at the same time. For these reasons, it is necessary to extract the maximum power from wind turbine. Our project is aiming to develop a small scale wind turbine simulator by a DC motor and a DC generator with appropriate control to maximize its output power.

Requirements

5.1.The first DC motor should simulate the behavior of a specific wind turbine, provide the same output torque and rotation speed under the same wind speed and load condition; Instead of using the real wind turbine, this project will use a DC motor to simulate the blades. A DC motor is to drive to generate the torque and pass the energy to the second DC motor. The speed of the first motor is accordance to the wind speed in the real situation. 5.2.The second DC motor should always acts as a generator; The second DC motor is going to be driven by the first DC motor and pass the mechanical power into the electrical power and deliver to the grid. Thus, it is important the second DC motor should operate as a generator, otherwise it will be abstract the power from the grid. 5.3.The 2nd motor should maximize the output power of the 1st motor by appropriate power electronic control; By using the appropriate electronic circuit, different output power could be achieved. In this project, H-bride will be used to make motors possible to operate in four quadrants. 5.4.Generator MPPT control algorithms should be able to work on both situations that the wind speed is known and unknown; 5.5.4 quadrants control should be applied; In this part, H-bride is planed to be used to make the DC motor operate in the four quadrants. This electronic circuit will be used before the DC motors and control the current flow into the motors. 5.6.Wind profile data should be very similar to the real wind data; Wind profile data should accordance with the real wind data. All experimental research should compared with real data from the wind farm. 5.7.All procedures should be simulated in Simulink before testing;