Projects:2019s1-119 360˚ Camera Dolly/Rig

Contents

Project team

Project members

- Chai Chang Zing

- Silin Wang

- Zeyu Zhang

- Yuhao Zhang

Supervisors

- Dr Said al-Sarawi

- Dr Hong Gunn Chew

Project Sponsors Adelaide Nursing School

- Dr Paul McLiesh

- Mr Christopher Kastelein

Background

Aim

To build a remotely controlled dolly/rig that can carry 360 camera and gimbal at varying heights.

Motivation

Allow students to use specific VR headsets to see the video from their perspective without seeing someone carrying the camera by hand.

Requirements

- Remotely controlled from a range

- Rotate on spot

- Accommodate a range of terrain types at variable speeds (walking speed)

- Accommodate variable height settings or mounted camera (0.8m-1.8m)

- Size of the device should limit outside the view of the device from the camera

- Easily transported and operated by a layperson

- Safety for people to use

Methods

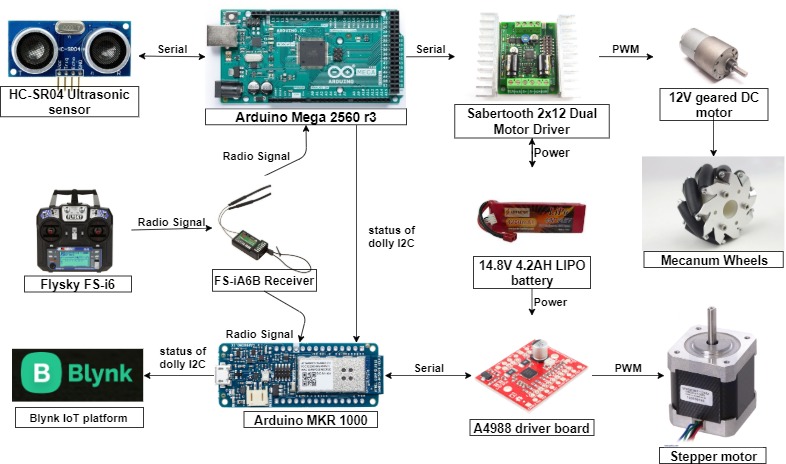

Wireless Control

- Using Radio Signal Wave (RC) to control the 360 camera dolly

- 2.4 GHz

- RC controller and receiver

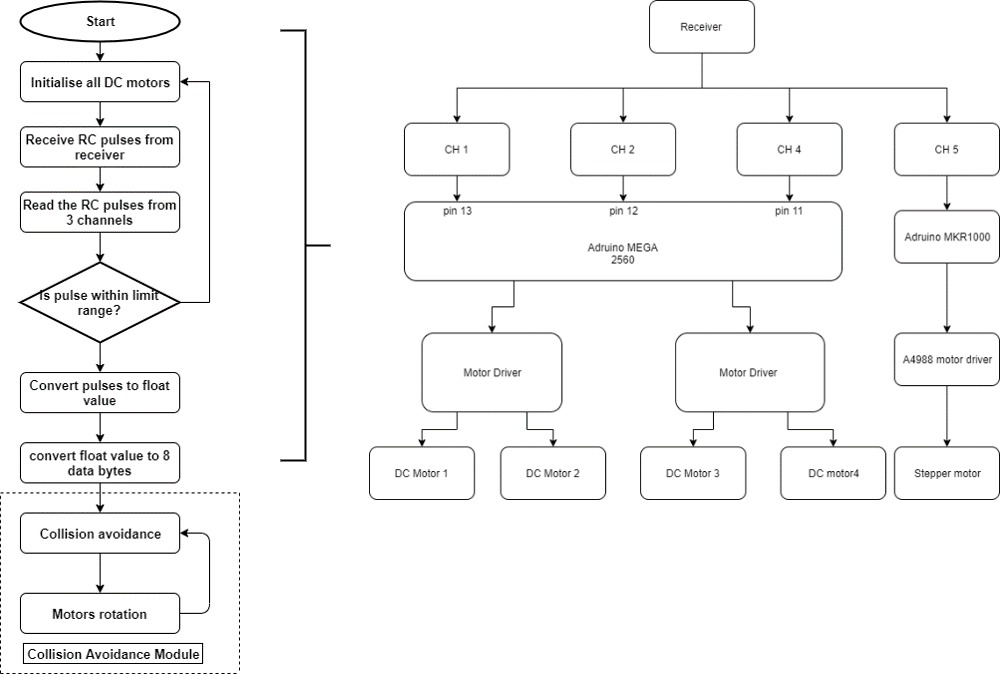

The RC controller transmit signal pulses and the Micro-controller receive and process the signal pulses.

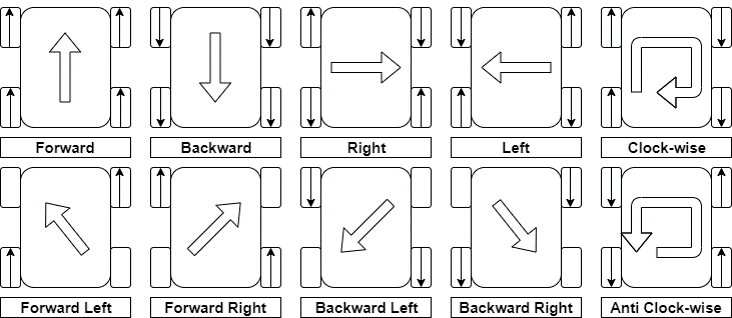

Movement Control

- 4 x 50:1 12V geared DC motor

- 2 x Sabertooth 2x12 dual regenerative motor driver

- Arduino Mega 2560 r3 - Micro-controller

There are 6 available modes in the Sabertooth motor driver. Packet-serial mode is selected to control the DC motors. The RF signal pulses received is converted into float value and then to bytes ranging from -127 to 127. The bytes from 0 to 127 indicates the speed of rotation of a motor while the positive and negative sign of the bytes indicates the direction of the rotation.

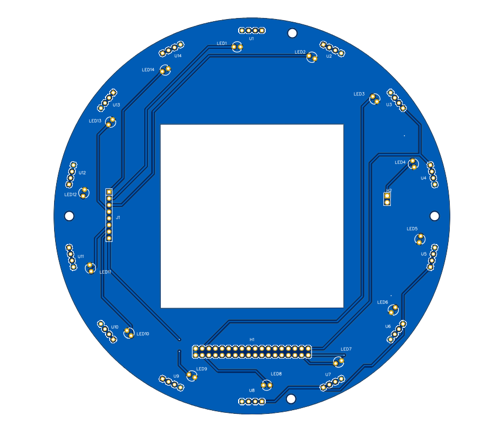

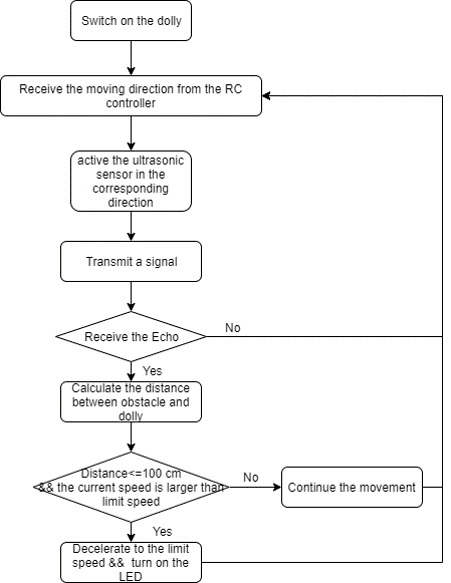

Collision Avoidance System

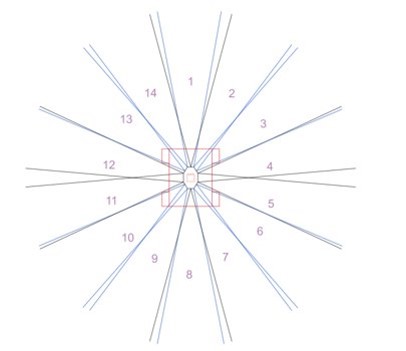

- Ultrasonic sensors - HC-SR04

- 14 Ultrasonic sensors for 360-degree coverage

- Each sensor can detect an object from 0.2 m to 4 m

The ultrasonic sensor can detect the distance of an object by calculating the time taken for an echo pulse from the object. The distance obtained is used in decelerating system of the dolly to reduce the effect of collision between the dolly and the obstacles. The deceleration distance is set at 0.8 m and the maximum speed of the dolly will be reduced according to the detected distance.

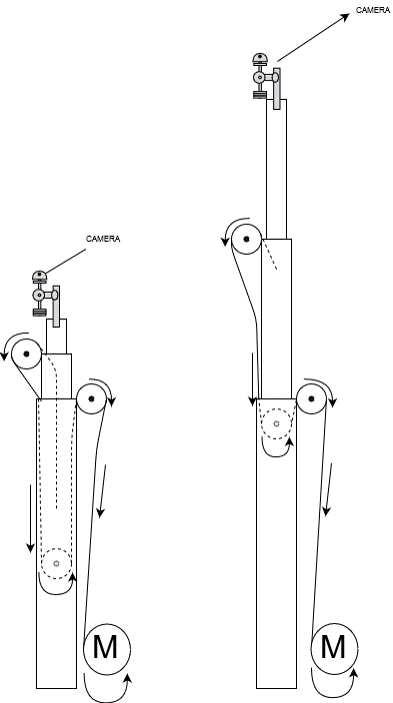

Telescopic Mast

- RC or Wi-Fi control

- Adjustable height from 0.8 m to 1.8 m

- 12V Stepper motor

- A4988 motor driver

- Arduino MKR 1000

Internet of Things (IoT)

Use the Arduino IoT (MKR1000) to display the status of 360 camera dolly which include speed, direction, distance and height of telescope mast.

Prototype

Hardware

Movement Control System

- Three channel used to control movement of dolly

- Each channel control two motion of DC motors

- The speed varies according to how much the joystick is pushed

- Movement control will be interrupt by the collision avoidance system

Collision Avoidance System

- Detecting angle of a sensor ~ 30°

- In order to achieve 360-degree detection, 14 sensors were used

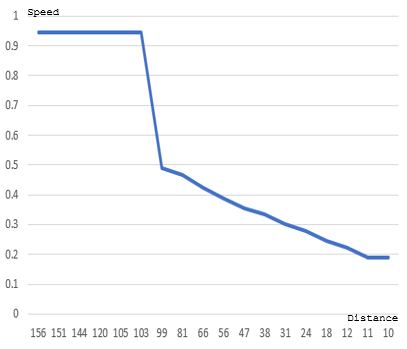

Speed control of Collision avoidance system

- Maximum Speed : 0.945 m/s

- Minimum Speed: 0.261 m/s

- The dolly starts to decelerate when the detected distance is smaller than 1 meter.

- It will reach the minimum speed when the obstacle is 0.1 meter away from the dolly.

Electric Telescopic Mast

- Using the pulse width signal to control the A4988 driver board to control the stepper motor rotate anticlockwise or clockwise.

- Stepper motor mounted with a spool that can release or collect rope.

- Using pulley system to implement the mast go up and down.