Projects:2015s1-61 Computer Aided Measurement and Analysis of Equal Efficiency Characteristics of Electrical Machines

Contents

Project Group 61 information

Topic

Computer Aided Measurement and Analysis of Equal Efficiency Characteristics of Electrical Machines

Team

Student

Ka Kit Poon

Zeyu Chen

Kejie Huang

Supervisor

A. Prof. Nesimi Ertugrul A. Prof. Wen Soong

Aim

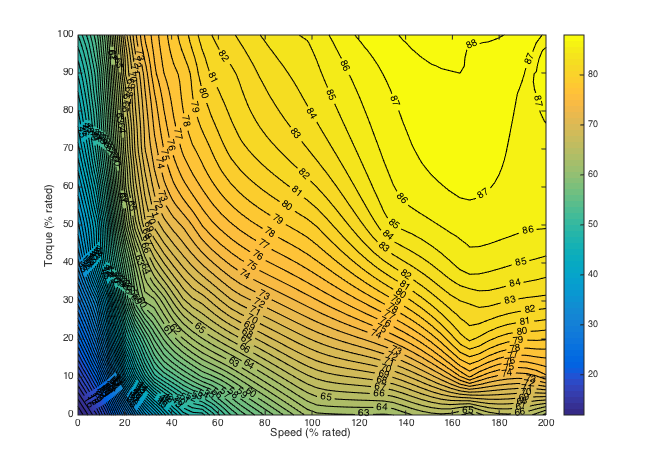

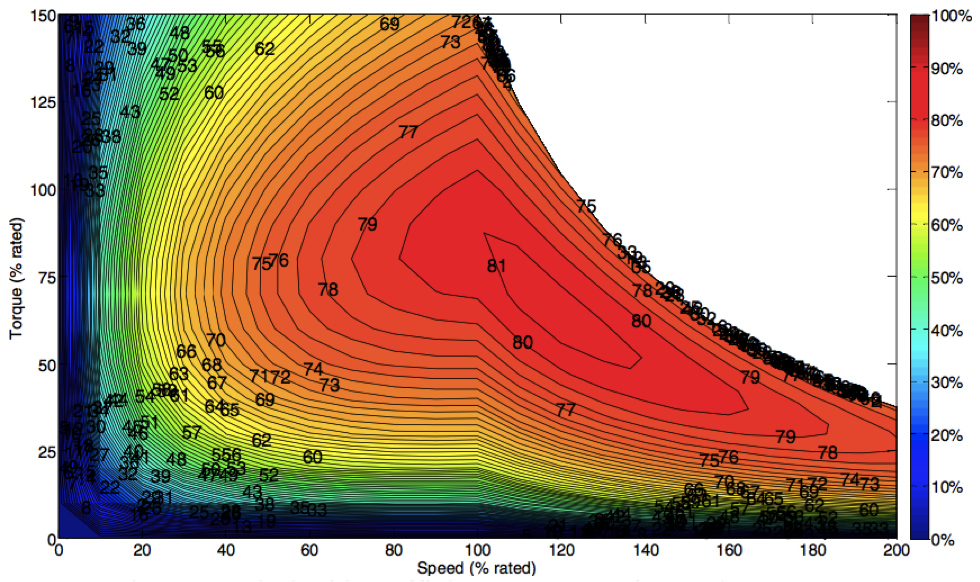

The main goals of the project is to explore the iso-efficiency map for a variety of electric machines, including brushed DC machines, switched reluctance machines (SRM) and squirrel cage induction machines (SC IM), compare and analysis the iso-efficiency maps of different types of electrical machine and try to predict the energy consumption for applications which require time-varying torque-speed operation. Iso-efficiency map is a new concept to describe the efficiency at each operating point in the operating region. The process involves machine testing, system setup, data acquisition to obtain the resulted iso-efficiency map to form a comprehensive view of electrical machine efficiency characteristics. The expected iso-efficiency map for electrical machine is similar with K. Stockman’s work [1], this is a typical iso-efficiency map for an induction machine.

Motivation

Iso-efficiency map describes the efficiency of each operating point on the torque-speed operating region. With the iso-efficiency map of each type of electrical machines, industry could predict the energy consumption in particular application and select the most efficient electrical machine, thus energy could be saved. In this project, the team carry out computer aided measurement and plotting of iso-efficiency map. It provided brief image about the efficient operating region of different machine.

Background

Proposed Approach

All electric machine will be tested in the Dynamometer system. One of the PHD student, Gabriel, has built the dynamometer system in the power laboratory at the University of Adelaide. The Machines will be integrated into the system. The development of computer interface for DC and Switched Reluctance Machine is one of major task in the integration. As the DC and SWR machine do not have a software-based interface, an interface board is required to built to allow computer control the drive. The USB DAQ 6009 is selected by the team and supervisor. It is I/O device that can transmit and receive digital and analogue signal.

DC Machine

Switched Reluctance Machine

Squirrel Cage Induction Machine

The SC IM is a 2.2 kW Baldor machine. The induction machine is widely used in the industry. The drive used is Motiflex e100. It has a user-friendly interface and facilitate software configuration via "Mint WorkBench". As the manufacture has designed computer interface between drive and computer, the integration into the system does not take much time compared with DC and SWR Machine.

Dynamometer System

Electric Machine is integrated into the dynamometer system. The system facilitate accurate measurement of efficiency. The Dyno machine acts as load and H2 drive controls the torque systemically. The function of computer is to send command to the drives and received data from measurement equipment. The control system monitor measured value and compare with reference value. The computer send speed and torque command to drive until certain condition is achieved.

Reasult - Iso-efficiency Map of SC IM

The Squirrel Cage Induction Machine is integrated and tested in the Dynomometer system. The 10x10 speed amd torque value is measured. The iso-efficiency map has been plotted in MATLAB. The result shows that the machine operate efficiently at relatively high speed and low torque rather than rated value. The lowest efficiency is at low speed. It is found that the efficiency is increasing when higher torque is added to the test machine. One of the limitation is overload operating region. As the machine can only run overload for short time, the data set above rated torque is missing.

Reference

[1] D. Vanhooydonck et al., “Calculating Energy Consumption of Motor Systems with Varying Load using Iso Efficiency Contours”, in XIX Int. Conf. Elect. Mach., Rome, 2010.

[2] W. Deprez et al., “Iso efficiency contours as a concept to characterize variable speed drive efficiency,” in 2010 XIX Int. Conf. on Elect. Mach. (ICEM), Sep. 2010, pp. 1-6.

[3] K. Stockman et al., “Iso efficiency contour measurement results for variable drives,” in 2010 XIX Int. Conf. on Elect. Mach. (ICEM), Sep. 2010. pp. 1-6.