Projects:2018s1-195 Novel Flexible Materials for Wearable Antennas

Contents

Project Team

Donald Dong Zhang

Dennis David Kimtai

Supervisors

Professor Christophe Fumeaux

Dr Shengjian (Jammy) Chen

Introduction

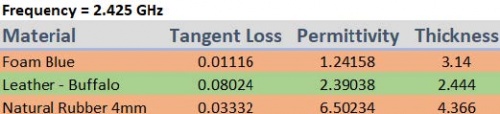

Natural Rubber, Buffalo Leather and Blue Foam are used as substrates for the realization of wearable antennas integrated into clothing.

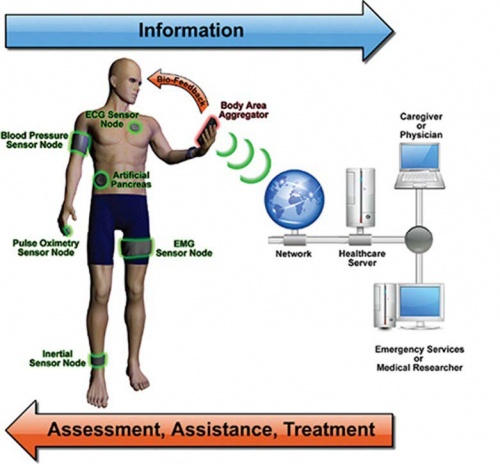

Background and Motivation

The reliability of wearable communication systems can benefit from high performance antennas integrated into clothing. Emerging wearable communications systems will increasingly require flexible antennas which can be integrated into clothing and are able to adapt their shape to various movement of the body. This will allow exploiting the area of clothing to create efficient antennas in critical applications such as communications and tracking for defence or safety personnel, or monitoring of patients in a hospital.

Aims and Objectives

This project considers the use of widely available flexible materials as substrates for the realization of wearable antennas. The project focuses on material characterization and related design aspects. It involves antenna theory and computer-assisted design with state of the art electromagnetic simulations tools.

Material Characterization

The substrates materials should be lightweight, small size, flexible and robust to achieve good communication characteristics without much variation in performance.

Design Aspect

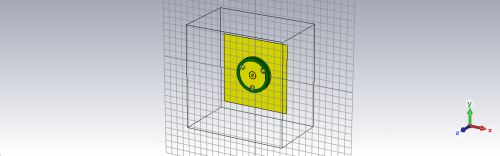

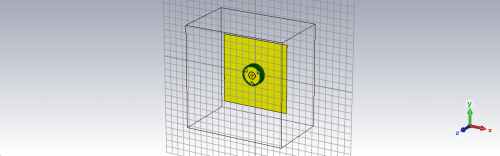

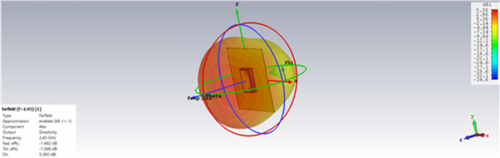

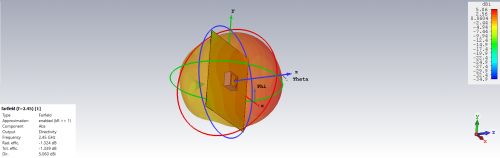

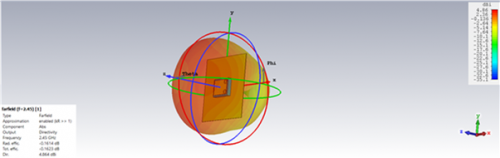

In this project antenna theory and computer simulation software (CST) was used to evaluate the use of different materials for two different types of wearable antennas:

- Monopole Antenna

- Planar Inverted-F Antenna (PIFA)

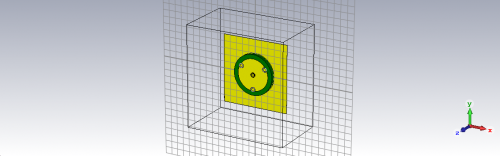

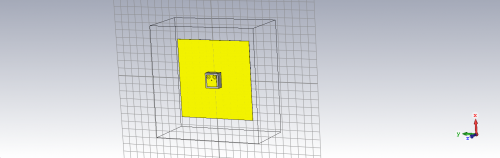

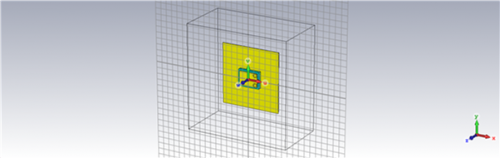

Monopole Antenna

Planar Inverted-F Antenna (PIFA)

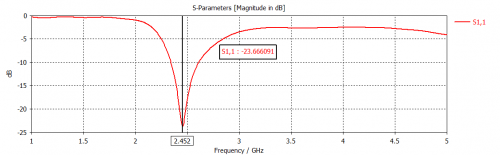

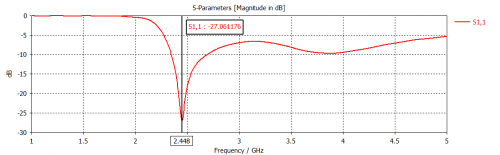

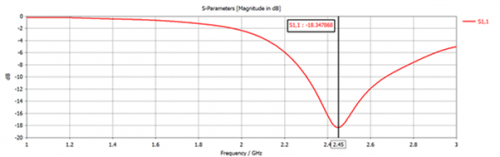

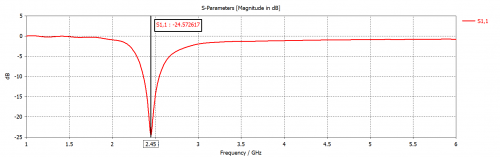

Simulation Results

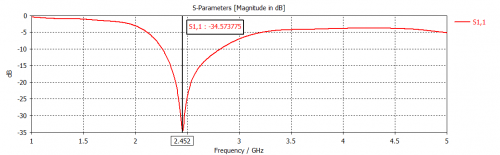

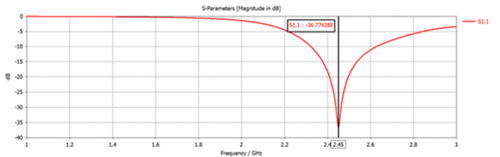

Reflection Coefficient

Monopole

PIFA

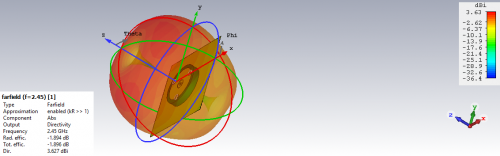

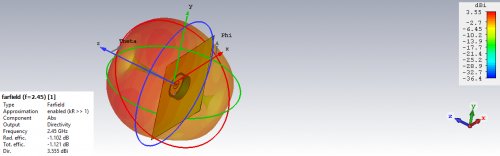

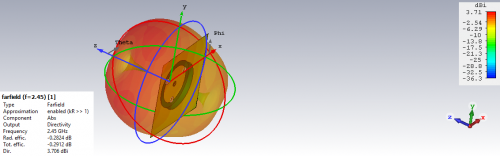

Directivity and Efficiency

Monopole

PIFA

E field distribution

Fabrication

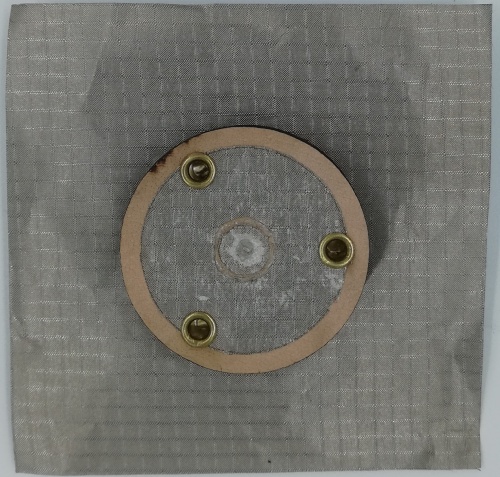

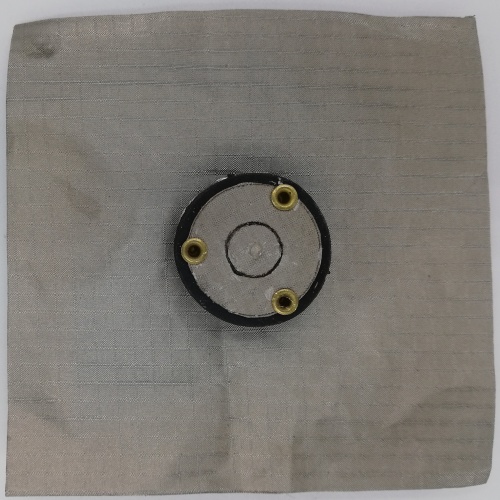

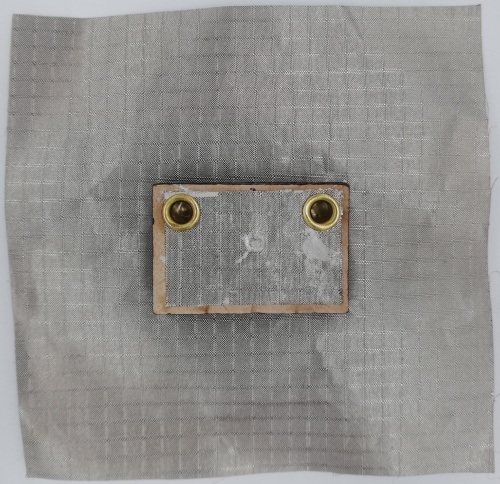

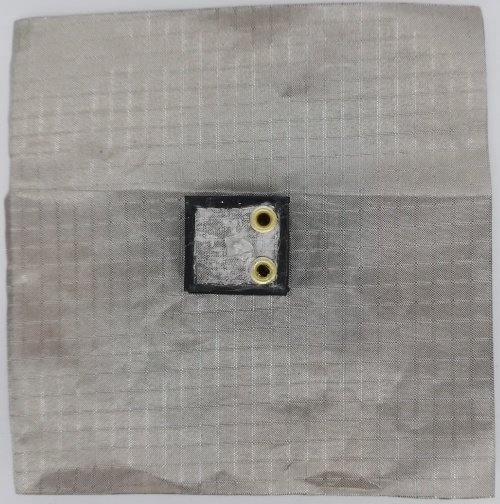

Monopole Antenna

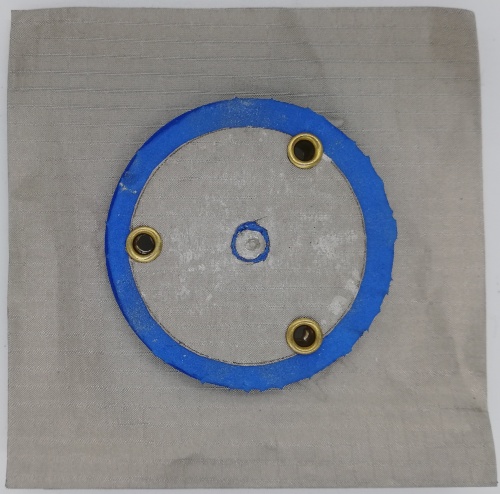

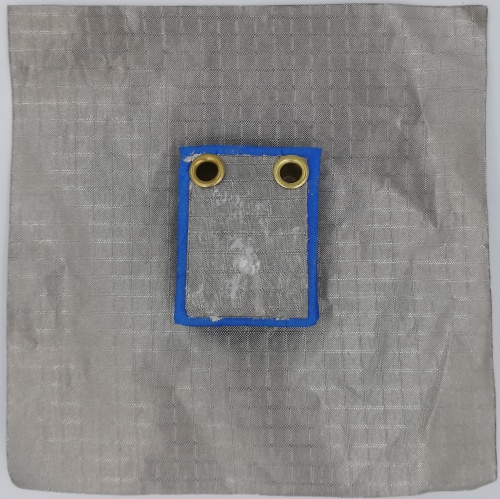

PIFA (Rubber Substrate)

Achievements

Fabrication results are expected to match the results from simulation.