Projects:2014S1-47 Robotic Arm for Trash Collecting Robot

This project will be working on an autonomous trash collecting robot. The focus of the group for this project will be on

the artificial intelligence and sensing aspects of the problem. A robotic platform already exists but the system will

need a robotic arm to pick up and items and place them in a bin.

Commercial arms are available, but a quick survey of what's available reveals that they are too small, not strong

enough or too expensive. The objective of this project is to either develop a custom arm for the purpose or to find a

commercial off-the-shelf arm and adapt it for the purpose, then to develop an interface for the trash collecting robot

to be agreed with the other group.

The arm may be used for other purposes including, for example, playing games or providing demonstrations at

University Open Days and exhibitions and a secondary objective is to develop an engaging demonstration of its

capabilities.

Contents

Introduction

This project will be on the artificial intelligence and sensing aspects of the problem. A robotic platform already exists but the system will need a robotic arm to pick up and items and place them in a bin. Commercial arms are available, but a quick survey of what's available reveals that they are too small, not strong enough or too expensive. The objective of this project is to either develop a custom arm for the purpose or to find a commercial off-the-shelf arm and adapt it for the purpose, then to develop an interface for the trash collecting robot to be agreed with the other group. The arm may be used for other purposes including, for example, playing games or providing demonstrations at University Open Days and exhibitions and a secondary objective is to develop an engaging demonstration of its capabilities.

Project Motivation & Previous Work

The robotic arm is one of the most useful pieces of technology to be introduced in the 20th century, and quickly became a cornerstone in many areas of manufacturing. It can be used for many different jobs and functions that may be too tedious, difficult or dangerous for a human to do. You might first think of the automobile industry when thinking about robotic arms, but they can be used for many other useful tasks besides welding and painting auto parts.

While working in a fashion similar to the human arm, robot arms can still have a much wider range of motion since their design can be purely up to the imagination of their creator. The joint that connects the segments of a robotic arm, for example, can rotate as well as moving like a hinge. The end of the robotic arm designed to actually do the work that it was designed for is known as the end effector, and can be designed for practically any task, for example gripping like a hand, painting, tightening screws and more. In our case it is design to pick up trash and place it in a bin.

There are few previous studies that have been done on trash collecting robot. Most of these studies are focusing on developing a trash-collecting robot for household where the robot navigates around the house and suck the dirt from the carpet or the floor. The TCR project however focuses on targeting general waste around the university.

Project Objectives

The project is aiming to develop a robotic arm that can be used for more than trash collection. A general interface also will be developed for the robotic arm enabling it to communicate with different platforms and performing different tasks. For this project to be considered a successful project the group has set a number of objectives to be achieved.

1. The robotic arm shall have at least 2 Degrees of Freedom (DoF).

2. The robotic arm shall be able to pick up trash weighting at least 370g.

3. The robotic arm shall have a total length of at least 50cm.

4. The gripper of the robotic arm shall be able to open at least as wide as a normal can.

5. The robotic arm shall give temperature, position, and load feedback to the agent.

6. The robotic arm shall be used for purposes other than trash collection such as playing games or demonstrations.

7. The robotic arm shall pose realistic movements (i.e. use IK to move in 3D space).

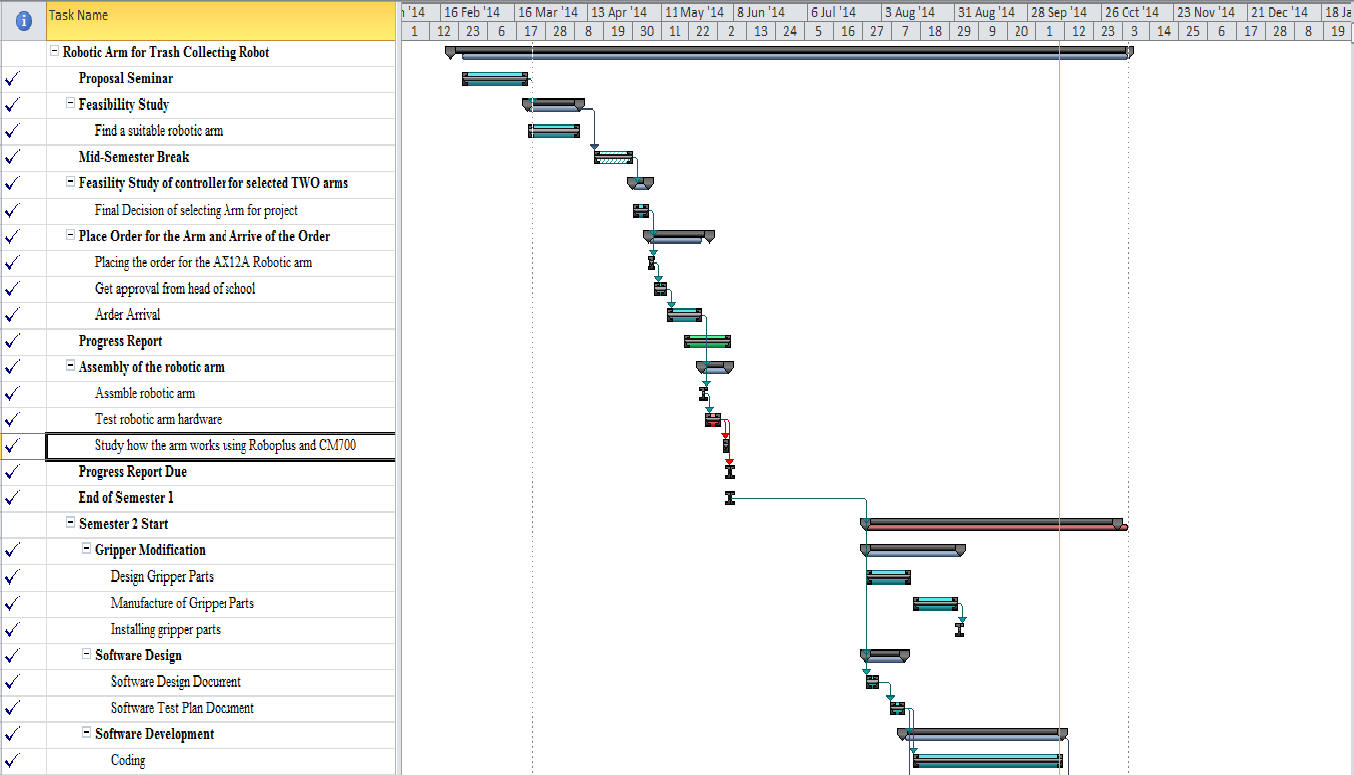

Project Plan

The project is developed base on the work of a team; the team includes two students, and two supervisors. A plan and life cycle of the project is established in the first two weeks. Additionally, every week, there is a meeting between students and supervisors; the content of the meeting is to report the progress of the project and future decision discussions. Individual tasking applied to the group members, include searching, individual planning, and documentations.

Hardware

The AX-12ACM700 Robotic Arm

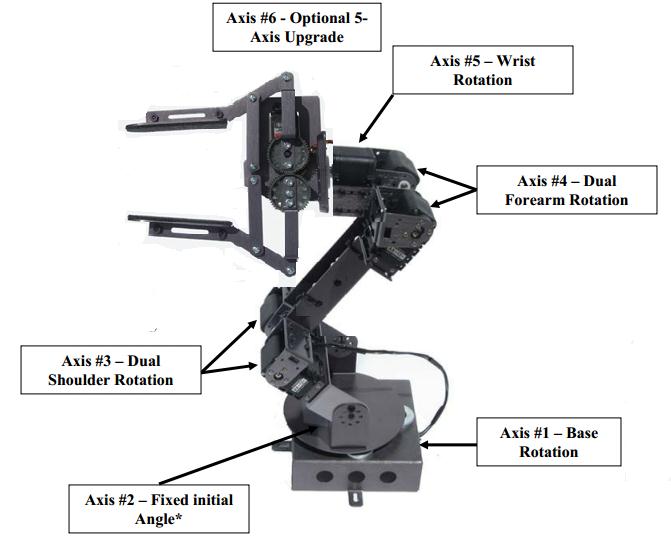

For the purpose of this project the group has decided to purchase an Off-The-Shelves robotic arm namely AX-12ACM700 shown in Figure 2. There are a number of reasons for why have the group chose the AX-12ACM700. The AX- 12ACM700 robotic arm is designed to be strong and rugged. It is constructed of anodized 0.063- gauge 5052 brushed finished aluminum components. It uses seven AX-12A actuators to provide 4 de- grees of freedom plus the gripper. Four of the AX-12As are paired up for the wrist and shoul- der joints, giving each of these joints up to 3 N- m of torque. The base, wrist rotate and grip- per joints use a single AX-12A with 1.5 N-m of torque. The gripper has a built-in adjustable sensor mount for installing cameras or other sensors [1].

Project Progress

The requirement for the robotic arm:

* Length approximately 50cm (Consider the size of a can and bin)

* A rotatable base that can be installed on any platform

* Arm and gripper should at least 4 degree of freedom

* Each joints and base element need to provides feedbacks

* Two finger gripper and sensor engineered

The concept of this arm allows the robotic arm to reach a point on the ground.

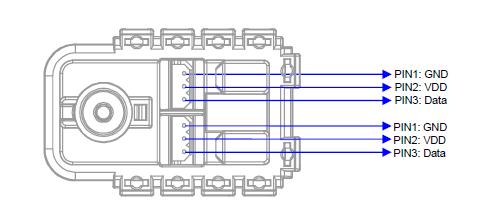

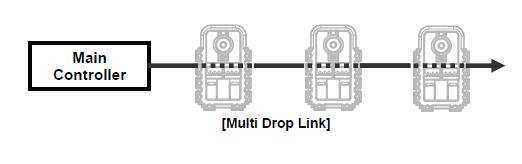

The robotic arm using the Dynamixel AX-12A servo, the servo has its compact size, it is a smart, modular actuator that incorporates a gear reducer, a precision DC motor , and a control circuitry with networking functions. It is made from high quality materials, can provides necessary strength and structural resistance to withstand large external forces.

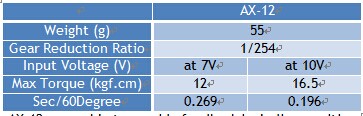

The table below summarized main specifications of AX-12 servo:

Additionally, AX-12 servo able to provide feedback including, position, Temperature, Load, input Voltage, etc.

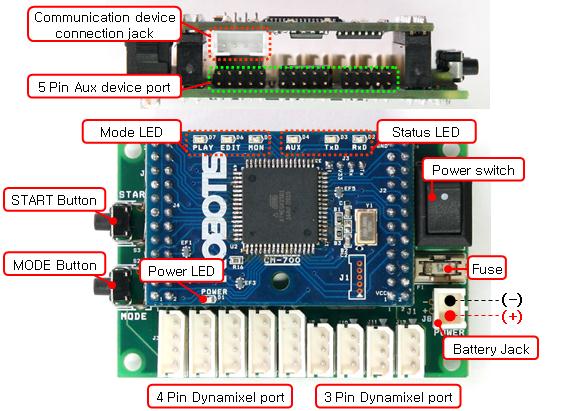

The controller used for the project is CM-700 which is a control module type controller with a CPU:

The controller require an external power supply from the user, when connecting the CM-700 and the SUB board the working voltage is between 7 and 35 volts.

When controller connected to AX-12 servo, the voltage range will be 9V ~ 12V.

The Li-Po conversion using 3 cells, meanwhile, the Ni-MH conversion using 8~10 cells.

We will program the CM-700 using PC, to be this the connection between PC and controller require a LN-101 USB downloader, as shown below:

Milestones

Milestone 1: Proposal Seminar (20th March 2014) Select Proposal Seminar as first milestone is because this is the first turning point for our project, which particularly means we switching Plan A build a robotic arm by ourselves to Plan B purchase one existing robotic arm.

Milestone 2: Final Decision of selecting arm for project (5th May 2014). The executed plan states that we extend our researching duration for find an arm to two weeks. At the beginning of the may we came out with a result of the selected arm, which is Cruscrawler AX12 Smart Robotic Arm.

Milestone 3: Placing the order for the AX12 Robotic Arm (7th May 2014) For ordering our selection of the robotic arm means our project tend to next stage

Milestone 4: Assemble robotic arm (27th May 2014) To finish assemble of the robotic arm, imply that project progress result match our executed plan, which means for the next semester or the time between two semesters we can start to program the arm, and interact with aims of the project.

Team Members

- Mr Junyu GUO

- Mr Salih Al Rashid

Supervisors

- Dr Braden Phillips

- Prof Michael Liebelt

Resources

Bench #7 Project Lab

“AX-12+ Smart Robotic Arm”, http://www.crustcrawler.com/products/AX18F%20Smart%20Robotic%20Arm/docs/Robot%20Smart%20Robotic%20Arm%20Review.pdf Last Accessed: 04/04/2014

“Robobench: Putting the CrustCrawler AX-12 Smart Arm to Work” http://www.crustcrawler.com/products/AX18F%20Smart%20Robotic%20Arm/docs/RoboBench_1.pdf Last Accessed: 14/04/2014

Royer,“A versatile, robust platform with intelligent feedback and precise control” http://www.crustcrawler.com/products/AX18F%20Smart%20Robotic%20Arm/docs/August2011AX12%20.pdf Last Accessed: 2/05/2014

“Robotis e-Manual-Ax-12A Servo” http://support.robotis.com/en/product/dynamixel/ax_series/dxl_ax_actuator.htm Last Accessed: 24/05/2014