Projects:2021s1-13153 Free-space optics for terahertz camera

Contents

INTRODUCTION

Project blurb

The project presents two passive optics structures operating at terahertz frequencies. One is a Wollaston prism the other is a broadband terahertz waveplates. Both structures rely on birefringence, where the propagation speeds of two polarisations is different. The prism separates two polarisations into different directions. For the broadband waveplate, the designs include half- and quarter- waveplates, which are designed and optimised via genetic algorithm. The operating frequency range is from 220GHz to 330GHz. Both structures are fabricated via 3D printing of cyclic olefin copolymer.

Acknowladge

Initially, thanks to our two supervisors, we did such a poor job in the project, and they still did not give up on us. Then, the team would like to thank Mr. Harrison Noel Lees for his kindness suggestions and assistance to produce the measurement. In addition, the team would like to thank Terahertz Laboratory for providing a platform for sample testing. Eventually, the sample is fabricated by 3D printing with the help of Mr. Hayden Westell.

Team members

- Hanwen Liu,

- Shenghao Gu

Supervisors

- Assoc. Prof. Withawat Withayachumnankul,

- Dr. Xiaolong You

Motivations

As passive optical elements, prism and broadband waveplate have very high research value in the field of wireless communications. In addition, based on 3D printing, the production cost and production cycle can be well controlled.

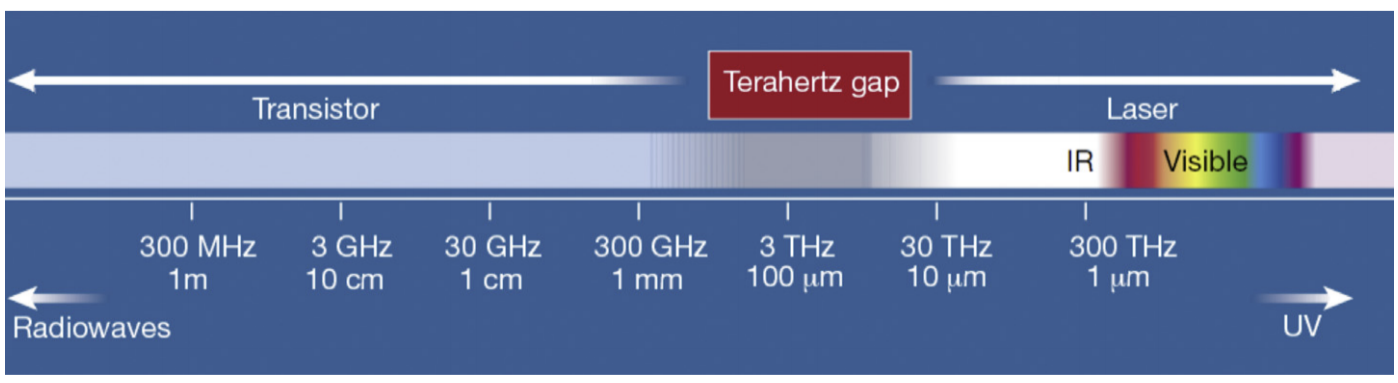

The terahertz wave

The terahertz frequency range span from 0.1 THz to 10 THz. In the electromagnetic spectrum, it falls between microwave radiation and infrared radiation. Hence it shares some properties with each of these.

Fig.1 Terahertz Spectrum

Refractive indices measurement

Since ultra-low loss cyclic copolymer (COC) is not a birefringent material, it is necessary to mix it with air. The team used Thorlabs RB13P1/M to measure the refractive indices of the sample and the calculation results are as follows.

3D printed Wollaston prism

It is an optical device that takes one beam of natural light in and outputs two beams of lights that have different polarisations. To understand the strategy of this, the team must understand the term birefringence. Birefringence is when a beam of light on an anisotropic crystal, is decomposed into two beams, the propagation speed is different, the polarization direction is perpendicular to each other, and the refractive index is different.

Design procedure

Traditional anisotropic materials are expensive and not easy to be shaped into designated structures. Hence, 3D printable material is chosen. One way to achieve anisotropy is to create a layer-by-layer structure using COC material and air gap. The length of each layer determines the frequency range in which the prism performs the highest quality. The angle of interface and length of layer together defines the angle difference between the output light and incident light. The performance of this prism can be characterized by the angle difference and extinction ratio.

Simulation results

220 GHz to 330 GHz operation frequency 180° phase retardation between E- and O- optics axes

Future work

To modify the interface angle and thickness of layer so that the two output rays are 90 degrees apart from each other. One piece of this prism may not be able to achieve this goal. Hence, three identical prisms will be combined to achieve the 90-degree separation.

The terahertz broadband quarter- and half- waveplates

The main purpose of the waveplate is to convert polarization. Its working principle is use of the anisotropy of birefringent materials. The phase retardation occurs due to the different refractive indices between ordinary and extraordinary. Half waveplate and quarter waveplate can be made by controlling refractive indices between two axes.

Design procedure

The layer is hybrid material obtained by mixing COC with air, the cost function is set with the thickness and rotation angle of each layer of the waveplate as variables. Moreover, a genetic algorithm is used to optimize the cost function. Eventually, the waveplate is fabricated based on 3D printing.

Results for quarter waveplate

220 GHz to 330 GHz operation frequency 90° phase retardation between O- and E- optics axes Axial ratio below 3 dB Extinction ratio greater than 15 dB

Results for half waveplate

220 GHz to 330 GHz operation frequency 180° phase retardation between E- and O- optics axes Extinction ratio greater than 15dB

Future work

Because the design of wave plate is based on Jones matrix. Therefore, it is not possible to calculate the loss caused by reflection. Thus, in the later work, The team need to use ABCD matrix to reproduce the whole structure.