Projects:2021s1-13006 Weather Station Solar Powered Battery System Optimisation

Contents

Introduction

ElectraNet operates a number of weather stations across the state of South Australia, from Leigh Creek to Mount Gambier. These weather stations are solar powered and equipped with batteries, allowing them to operate in remote areas without an external power source. ElectraNet is looking to change the operating capabilities of the DC power system and to better optimise the power system.

The operational requirements, sensor power budget and historic weather data will be used to guide the evaluation and design of the 12 V DC power system. This includes assessing the solar panel sizing and performance at different locations in the state, and under different operating conditions. The charger and battery performance will also be considered, with a focus on the impact of temperature on battery capacity over the planned life of the system. The enclosure design is also expected to contribute to the performance of the overall DC power system. The outcomes of the project will include a power budget, the design of the DC power system, and selection of components including the solar panel, charger, battery, and enclosure that meet the requirements of the weather sensor and remote terminal unit. The system lifecycle will also be evaluated, including the operability and maintainability of the system.

Project team

Project students

- Riley Bass

- Matthew Grear

Supervisors

- A/Prof Dr. Nesimi Ertugrul

- Dr. Gabriel Haines (ElectraNet)

Objectives

Develop a full design of a new and optimised PV and battery powered weather station that meets the following requirements:

- The system is DC and completely off grid.

- The battery must remain above 50% state of charge (SOC) for at least 7 days with minimal solar irradiance.

- The battery must last at for least 5 years.

- Preferred one design to fit all weather station locations.

- The ability to accommodate future component upgrades.

Background

Dynamic Line Ratings

A cheap, consistent, and reliable flow of electricity is desired by all customers. It is the Transmission Network Service Providers (TNSP’s) duty is to continually discover, innovate and maintain ways to deliver these outcomes. In South Australia, TNSP ElectraNet have implemented Dynamic Line Ratings (DLR) throughout their Network.

Traditionally, Static Thermal Ratings have been used in transmission lines, to determine the amount of permissible current through the given line. In reality, the permissable amapacity of transmission lines are constantly changing, depending on various factors that the transmission line is subjected to. Dynamic Line Ratings use live weather data to actively alter the ampacity current rating of transmission line [1]. In good cooling conditions (e.g., low ambient temperature) DLR raises limits to allow higher current to pass through the relevant transmission line, and in hot conditions (e.g. high ambient temperature), DLR reduces the the line ampacity to prevent overloading issues. Figure 1 shows how DLR alters the line ampacities based on weather conditions. In comparison to Static Ratings, DLR enables Transmission Networks to optimise grid usage, minimise grid congestion and capitalise on economic opportunities [1]. This is increasingly important, as the proportion of Non-Scheduled Generation (Solar PV and Wind) continues to rise, and more line capacity is needed at times to meet the output of these renewable energy sources.

Stand-Alone Capability

A large majority of ElectraNet weather stations are situated in remote locations, or where the only source of electricity is at unsuiatable levels (e.g. 275kV, 133kV). Therefore, the weather stations must be stand-alone, and generate it's own electricity. For such applications, Solar PV panels are commonly used, as they are reliable, relatively inexpensive, and easy to maintain. Due to these reasons, the project will design a project using Solar PV as its sole electricity provider. Wind energy could be considered for this project; however, it adds unnecessary complexity, and brings a further point of failure to the overall system.

Solar PV panels harvest their energy directly from the Sun every day. Solar Radiation is an infinite energy resource, easy to maintain and install, and relatively cheap, making it ideal for a remote system . A key limitation of Solar, however, is the intermittent nature of the energy source. The sun rises throughout the morning, peaks at approximately midday, and then disappears at night-time. As a result, the daily energy output for a Solar PV panel has the approximate shape of the supply curve below.

Due to the intermittency of solar radiation, Solar PV alone will not be able power the weather station during the night. To provide a constant power, an energy storage device can be used. This will capture excess Solar PV energy throughout the daytime and use this energy at night. Batteries provide an ideal energy storage solution for this application, due to their simplicity and high energy density.

ElectraNet Weather Stations

Creating DLR’s requires the use of Weather Stations, to transmit live data to the TNSP. The stations must be strategically positioned around a transmission network for an accurate DLR determination to be formed. South Australia’s TNSP, ElectraNet, own 93 Weather Stations, around the network due to this. As the ElectraNet network spans over many rural areas, they are required to be stand-alone structures, and provide their own energy needs. Due to this, ElectraNet’s Weather Stations are currently fitted with a Solar PV system to power the necessary devices.

ElectraNet's existing PV System is made up of several components to facilitate the entire process. These are a Solar PV, Lead-Acid Battery, RTU+Modem, Weather Monitor, Irradience Monitor, and Solar Charger. The load components used for this design are shown below. Therefore, the system uses a 20W Solar Panel, and a 26Ah Lead-Acid Battery to power a 133mA load.

| Load Component | Load (mA) - 12V |

|---|---|

| Solar Charger | 8mA |

| RTU+Modem | 105mA |

| Weather Monitor | 15mA |

| Irradience Monitor | 5mA |

| Total Load | 133mA |

- Error creating thumbnail: Unable to save thumbnail to destination

ElectraNet Weather Station

- Error creating thumbnail: Unable to save thumbnail to destination

"see-saw" pole

Investigation

Modelling

PV Watts

PVWatts is a software tool designed by the National Renewable Energy Laboratory (NREL), a U.S government-funded agency. Using PVWatts, the modelling can be performed. PVWatts uses advanced irradiance measurement tools from select locations in South Australia, to determine beam irradiance, diffuse irradiance, and therefore compute the Plane-of-Array irradiance(Itr).Utilising wind speed, dry bulb temperature, and POA irradiance, PV Watts calculates Solar Cell temperature, Tcell. The overarching equation used by PVWatts to determine DC output is:

Sizing Analysis

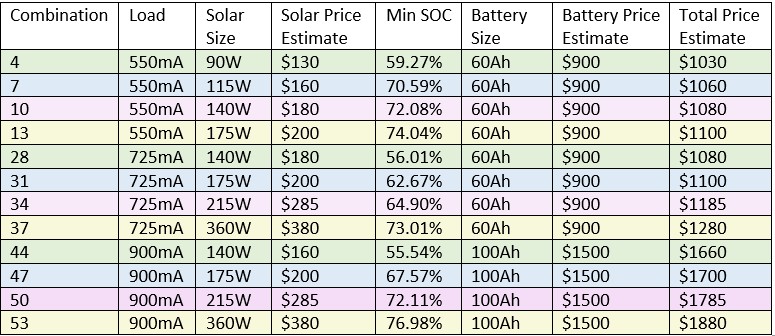

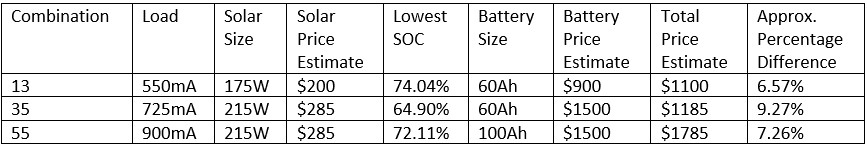

Using PVWatts, many different options for sizing the battery and panel were modelled. The sizing designs that satisfied the requirements were selected from the original options. From there, the 4 most economical combinations for each load were summarised:

This found that, as the price of Solar PV is relatively cheap, there was generally less than 10% difference from the first and fourth cheapest combinations. Prices that are within 10% of the cheapest optionare therefore considered for the final designs. By doing this, the system is given more strength and security. The sizing for each load was therefore:

- Error creating thumbnail: Unable to save thumbnail to destination

Lower Load Estimate - 550mA

- Error creating thumbnail: Unable to save thumbnail to destination

Mid Load Estimate - 725mA

- Error creating thumbnail: Unable to save thumbnail to destination

Upper Load Estimate - 900mA

Remote Diagnostics

SOH Monitoring

State of Health (SOH) indicates the relative health of a given battery. For lithium-ion batteries, there is no universal, or clearly defined method, to find the overall health of a Li-ion battery at a given time. Some battery manufacturers determine the SOH by the number of cycles the battery has been through, however, this does not consider the effects of temperature. There are, however, multiple methods which are common throughout literature, that are helpful to provide insight into a batteries realistic SOH.

These are:

- Capacity Test

- Open Circuit Voltage Test

- Internal Resistance

- Load Behaviour

SOC Alarms

Although there are common methods to approximate the SOH in lithium batteries, there is no model that is universal, or known to be particularly accurate. Therefore, there are little commercial devices measuring SOH. However, to meet the requirements, remote battery diagnostics must be provided, so that when battery replacements are necessary, they can be scheduled and planned before the weather station becomes unavailable. As there are over 50 ElectraNet weather stations, it is unreasonable to think the ElectraNet weather station operator will be constantly checking all the battery diagnostics for all stations. Therefore, an alarm system is needed to divert attention to the weather stations as they require it. The alarm system should trigger when the battery is operating unusually, prompting the operator to analyse SOH using the previously mentioned techniques. One method of doing this is to set an alarm for low SOC. To meet the requirements, an SOC alarm should be triggered below 50% SOC. Low voltage could also be made an alarm with similar effects.

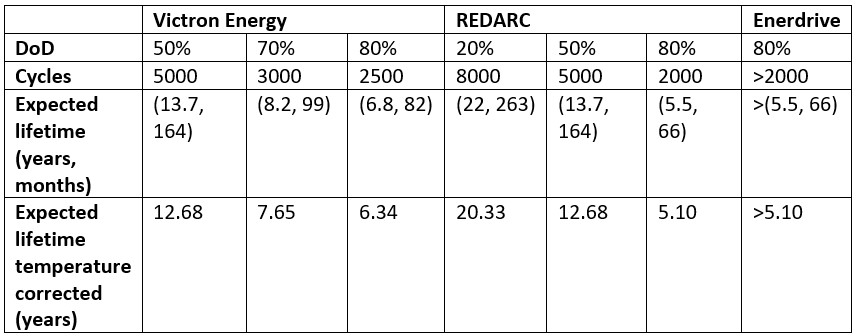

Battery Degradation Prediction

DOD

Most Lithium Battery Manufacturers list the predicted cycle life of their batteries for given Depth of Discharge.

Arrenhious

Through extensive literature research, it can be concluded that there are no universal, or industry accepted models for the degradation of lithium batteries. The Arrhenius Equation is one of the most widely used battery degradation models, however, was designed for lead-acid batteries. The model will still however provide valuable insight of potenetial degradation rates, especially in regions with hot climates.

To use the Arrhenius equation effectively, real weather data is required. IEEE Standard 450-2020 defines a formula based on the Arrhenius equation to determine the temperature corrected years of life of a vented lead-acid battery. As lithium-ion typically degrade less than lead-acids in hot weather, this approach will produce a conservative estimate of the battery lifetime in hot environments.

- Error creating thumbnail: Unable to save thumbnail to destination

temperature corrected life of LFP Batteries

- Error creating thumbnail: Unable to save thumbnail to destination

Approximate thermal degradation curve for lead-acid battery life versus average battery temperature.

- Error creating thumbnail: Unable to save thumbnail to destination

Dry Bulb Temperature at Roxby Downs

Battery Life Prediction

Therefore, considering the above, the predicted life for LFP batteries can be formed. Using data from popular and reputable Australian lithium-ion battery suppliers, the following temperature corrected battery lifetime is computed. The following batteries analysed are all 12V 100Ah lithium-iron-phosphate (LiFePO4 or LFP). It is assumed that 1 full cycle is equal to 1 full day of operation. CSIRO TMY dry-bulb monthly temperature data can be used as a typical temperature for the batteries. Roxby Downs is used as a decent representation of a ‘worst-case’ scenario for weather stations temperatures in Leigh Creek and Olympic Dam.

System Description

Solar PV

Monocrystalline Solar PV Panels will be used in this project, as they offer superiour efficiencies. Voltage output from these panels can be up to 75V, as the MPPT Charger can facilitate this (see below). Due dilligence must be applied to find the best Provider, which offers the best price, and technology support. Some reputable Australian Providers are REDARC and Victron Energy

LFP Battery

Lithium-Ion Batteries, specifically Lithium-Iron-Phosphate (LFP) are used in this project, because of the batteries energy density, lifetime, and temperature performance. Due dilligence must again be applied to ensure the best price and technical support when purchasing the battery. The designs of this project require 60 Ah, or 100Ah 12V batteries.

Solar Charger - MPPT

The solar charger protects the battery, as well as serve the load, and convert the solar voltages to 12V (system voltage). Victron Energy's MPPT was selected to use, as it is designed to suit LFP batteries, has a low temperature disconnect to preserve the battery, and has efficiences greater than 98%.

Maximum Power Point Tracking (MPPT) instead of Pulse Width Modulation (PWM) used in the existing system. MPPT's are used to optimise the power throughout the day. An MPPT Charger does this by controlling the duty cycle of the DC-DC converter, so that the IV curve is always at Pmax.

- Error creating thumbnail: Unable to save thumbnail to destination

MPPT Tracking

- Error creating thumbnail: Unable to save thumbnail to destination

PWM Example

- Error creating thumbnail: Unable to save thumbnail to destination

MPPT Example

RTU

The RTU is the largest load on the system and is responsible for logging all the data from the sensors and sending it back to an ElectraNet central server via the modem.

Modem

The modem is responsible for transimitting information stored in the RTU back to ElectraNet.

Battery Monitor

The Battery Monitor obtains data from the Battery and transmits the information through the RTU and Modem. Alarms will also be generated with the Battery Monitor.

Overall System

The following pictures depict the overall system

- Error creating thumbnail: Unable to save thumbnail to destination

100Ah Cabinet Layout

- Error creating thumbnail: Unable to save thumbnail to destination

60Ah Cabinet Layout

- Error creating thumbnail: Unable to save thumbnail to destination

Remote Diagnostics and Alarms

Conclusion

In conclusion, three designs will be submitted to ElectraNet, based on 3 future load estimates (lower,mid, and upper estimates). These designs have been chosen to meet all requirements, while providing an economically sensible choice. By redesigning ElectraNet's weather stations, there will now be invaluable about the condition and health of the battery. The battery life is expected to be greater than 5 years, which will significantly reduce ElectraNet's operational costs. By considering future devices and elements, this designed system will be viable to use for many years to come.

References

[1] J.-L. Repetto, A. Michiorri, H. Anuta, G. Nai, L. Casado, E. Ocenic, N. Litman-Roventa, M. Lyons and P. Komor, “Innovation landcape brief: Dynamic line rating,” IRENA, Abu Dhabi, 2020.

[2] K. Goksin, J. McNerney and J. Trancik, “Evaluating the causes of cost reduction in photovoltaic modules,” Energy Policy, vol. 123, pp. 700-710, 2018.

[3] REDARC, “Lithium Deep Cycle Batteries,” REDARC, 2021. [Online]. Available: https://www.redarc.com.au/deep-cycle-batteries. [Accessed 26 4 2021].

[4] Beureau of Meteorology, “Maps of average conditions,” Australian Government, 2021. [Online]. Available: http://www.bom.gov.au. [Accessed 13 4 2021].

[5] C. Honsberg and S. Bowden , “Summary and Comparison of Battery Characteristics,” PV Education, 2019. [Online]. Available: https://www.pveducation.org. [Accessed 12 5 2021].

[6] M. Mobbs, “Lead Acid vs Lithium Ion Thermal Effects,” Sustainable Projects, 2018. [Online]. [Accessed 29 3 2021].

[7] X. Han, L. Lu, Y. Zheng, X. Feng, Z. Li and J. Li, “A review on the key issues of the lithium ion battery degradation among the whole life cycle,” ELSEVIER, p. 21, 2019.

[8] G. M. Masters, “Solar Position At Any Time Of Day,” in Renewable and Efficient Electric Power Systems, Stanford, John Wiley & Sons, Inc, 2004, pp. 413-420.

[9] G. Masters, Renewable and Efficient Electric Power Systems, Stanford: John Wiley & Sons, Inc, 2004.

[10] H. Louie, Off-Grid Electrical Systems in Developing Countries, Seattle: Springer International Publishing, 2018.

[11] NREL, “PV Watts,” U.S Department of Energy, [Online]. Available: https://pvwatts.nrel.gov/pvwatts.php. [Accessed 15 4 2021].

[12] J. Deign, “Green Tech Media,” Wood Mackenzie , 21 September 2020. [Online]. Available: https://www.greentechmedia.com/articles/read/how-south-australia-is-dealing-with-rampant-solar-growth. [Accessed 19 5 2021].

[13] J. Vetter, P. Novak, M. Wagner, C. Veit, K. Moller, J. Besenhard, M. Winter, M. Wohlfashrt, C. Vogler and A. Hammouche, “Ageing mechanisms in lithium-ion batteries,” Journal of Power Sources, vol. 147, no. 1-2, pp. 269-281, 2005.

[14] N. Lin, Z. Wang, H. Zhao, G. Ai, X. Song, Y. Bai, V. Battaglia, C. Sun, C. Sun, J. Qiao, K. Wu and G. Liu, “Understanding the crack formation of graphite particles in cycled commercial lithium-ion batteries by focused ion beam - scanning electron microscopy,” Journal of Power Sources, vol. 365, pp. 235-239, 2017.

[15] J. Christensen and J. Newman, “Effect of anode film resistance on the charge/discharge capacity of a lithium-ion battery,” Journal of Electrochemical Society, vol. 150, no. 11, pp. 1416-1420, 2003.

[16] R. Deshpande, M. Verbrugge, Y.-T. Cheng, J. Wang and P. Liu, “Battery Cycle Life Prediction with Coupled Chemical Degradation and Fatigue Mechanics,” Journal of the Electrochemical Society, vol. 159, no. 10, 2012.

[17] R. Hausbrand, G. Cherkashinin, H. Ehrenberg, M. Groting, K. Albe, C. Hess and W. Jaegermann, Fundamental degradation mechanisms of layered oxide Li-ion battery cathode materials: Methodology, insights and novel approaches, Darmstadt: Institute of Materials Science and Institute of Physical Chemistry, 2014.

[18] T. Waldmann, M. Wilka, M. Kasper, M. Fleischhammer and M. Wohlfahrt-Mehrens, “Temperature dependent ageing mechanisms in Lithium-ion batteries – A Post-Mortem study,” Journal of Power Sources, vol. 262, pp. 129-135, 2014.

[19] J. Jiang, W. Shi, J. Zheng, P. Zuo, J. Xiao, X. Chen, W. Xu and J.-G. Zhang, “Optimized Operating Range for Large-Format LiFePO4/Graphite,” Journal of the Electrochemical Society, pp. 337-344, 2014.

[20] E. Wikner and T. Thiringer, “Extending Battery Lifetime by Avoiding High SOC,” Applied Sciences, pp. 1-16, 2018.

[21] Battery Space, “Lithium Iron Phosphate Battery,” Battery Space, 2018. [Online]. Available: https://www.batteryspace.com/prod-specs/9055.pdf. [Accessed 27 4 2021].

[22] a. Peresan, S. Santhanagopalan and G. Kim, “Addressing the Impact of Temperature Extremes on Large Format Li-Ion Batteries for Vehicle Applications,” in 30th International Battery Seminar, Florida, 2013.

[23] S. Ma, M. Jiang, P. Tao, C. Song, J. Wu, J. Wang, T. Deng and W. Shang, “Temperature effect and thermal impact in lithium-ion batteries: A review,” Progress in Natural Science: Materials International, pp. 653-667, 2018.

[24] G. Nagasubramanian, “Electrical characteristics of 18650 Li-ion cells at low temperatures,” Journal of Applied Electrochemistry, vol. 31, no. 1, pp. 99-104, 2001.

[25] J. Godby and C. Ashton, “Temperature of equipment/battery cabinets in non-controlled environment locations in Pheonix, AZ,” IEEE, Lakewood, 1994.

[26] Apply Solar Shielding to Lessen Heat Load, Protect Enclosure Components. [Performance]. Hoffman, 2009.

[27] M. Dubarry, N. Qin and P. Brooker, “Calendar aging of commercial Li-ion cells of different chemistries – A review,” Cross Mark, vol. 9, pp. 106-113, 2018.