Projects:2014S1-04 All Electric Vehicle for City Use

This project is a continuing project from 2008. The aim of the project in this year is to build an electric vehicle driving system to achieve the road test and data logging.

Contents

Project information

Motivation and Background

- Facing the increasing air pollution and Carbon Dioxide emissions, the electric vehicle is a feasible alternative choice of traditional vehicles with internal-combustion engines.

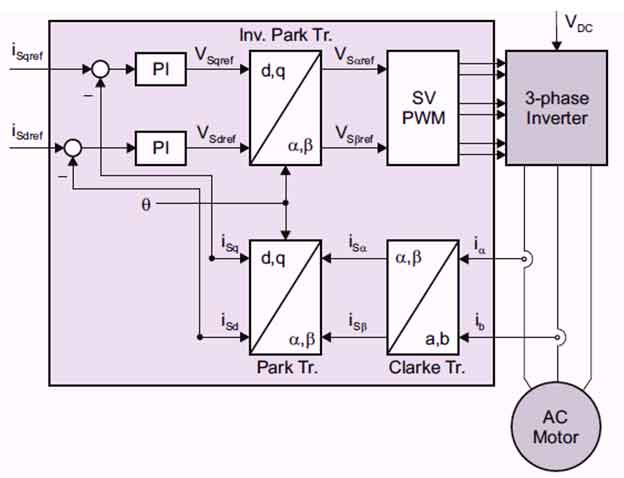

- The most significant electric motor control principle applied in this project is the Field Oriented Control (FOC). In the operation, two phase currents of motor are sampled and converted into a two co-ordinate time invariant system by Clarke Transformation and Park Transformation. By controlling the converted torque component, we can achieve the torque control as well as speed control.

Previous work

Previous years' student have developed and integrated the battery and charging system with its monitoring system, buck and boost converter, motor selection and isolation parts. For the motor driving system, Semikron SKAI5001 inverter was used to be controlled by Digital Signal Processor (TMS320F2407). This inverter was used as the main electronic device to convert DC power from battery to AC waveforms. However, the tests of Semikron inverters (either Semikron 3001 or Semikron 5001) failed in last few year. Also, the TOYOTA Prius inverter was highly recommended by last year's students consider its high power and reliable SPI communication with high-resolution current sensors. However, this inverter did not work at all after connecting to power supply. Thus, the motor control part should be built based on a new inverter and a new Digital Signal Processor.

Project Aims

The aim of this project is to converter the MAZDA MX5 with internal combustion engine to an electric vehicle use electrical energy for city use. This year, the project group is expected to achieve motor control (Field Orientated Control) based on operations of an inverter, current and position sensors that controlled by a Digital Signal Processor. The inverter, current sensors and position sensors are all required to be selected and ordered during the year to meet requirements.

Outline of proposed work

- Order and test Resolver to Digital Converter

- Integrate DSP with Resolver to digital converter

- Achieve Serial Peripheral Interface communication in DSP

- Order and test current sensors

- Integrate DSP with current sensor

- Achieve ADC control in DSP

- Test TOYOTA Prius Inverter

- Test SemiTeach Inverter

- Integrate DSP with inverter

- Achieve inverter control in DSP

- DSP programming for FOC control

- Motor test

Milestones

- Proposal Seminar. (Week3, Semester1)

- Inverter switching test and verify the functionality of inverter. (Week4, Semester1)

- Connected and tested Resolver to Digital converter to the vehicle. (Week8, Semester1)

- Generate PWM signal from DSP by programming using Code Composer. (Week9, Semester1)

- Progress Report. (Week12, Semester1)

- Connected and tested current sensors. (Week13, Semester1)

- Apply 120 degrees and 180 degrees conduction tests to the inverter. (Week1, Semester2)

- Achieve ADC control and sample the output from current sensors in DSP. (Week3, Semester2)

- Achieve SPI communication between DSP and Resolver to Digital Converter. (Week5, Semester2)

- Obtain the rotor position detection. (Week7, Semester2)

- Apply FOC open loop test to generate corresponding space vector PWM signal based on initial settings of variables. (Week 8, Semester2)

- Motor Test (TBA)

- Final Seminar (Week10, Semester2)

- Final Report (Week11, Semester2)

- Exhibition (Week12, Semester2)

Team

Group members

- Mr Shuaiqi Cao

- Ms Shiyun Zhao

Supervisors

- Prof Nesimi Ertugrul

- Dr Andrew Allison