Projects:2015s2-202 An On-line PLC frequency Impedance Analyser

Contents

Introduction

Electricity is the most versatile and widely used form of energy and global demand is growing continuously. To satisfy the increasing demand for power, we need an electric system that can handle these challenges in a sustainable, reliable and economic way. Thus Smart grid is proposed. In order to effect the required coordination between generating units, interconnecting transmission lines and users, it is necessary that there be effective and reliable communication between them, PLC is used for this purpose. PLC can be used to read smart electricity meters and control the Smartgrid. However, According to maximum power transfer theorem, in order to design a suitable power line coupler so that signals and messages can be more efficiently transferred through the power line, the impedance of a power line and its daily typical impedance variations needs to be known. An accurate on line impedance analyser that can be used to measure the impedance of a Power line in the frequency range from 5 kHz to 5 MHz is required. The impedance analyser is supposed to be easy and convenient to use, simply attach two probes onto power lines and by reading the resulting voltage and current we can obtain the impedance. Fig 1 is a simplified graph shows how to use the analyser.

Objectives

The aim of this project is to build an on-line impedance analyser that is used to measure the impedance of a power line at PLC frequencies so that information can be effectively transferred through a power line coupler. This project includes several phases, first of all, the circuit optimization phase using computer-based tool AWR, second phase is the PCB designing phase which involves the design, construction and testing of the PCB. The last phase involves measuring impedances from different locations inside the University of Adelaide.

Middle Sections

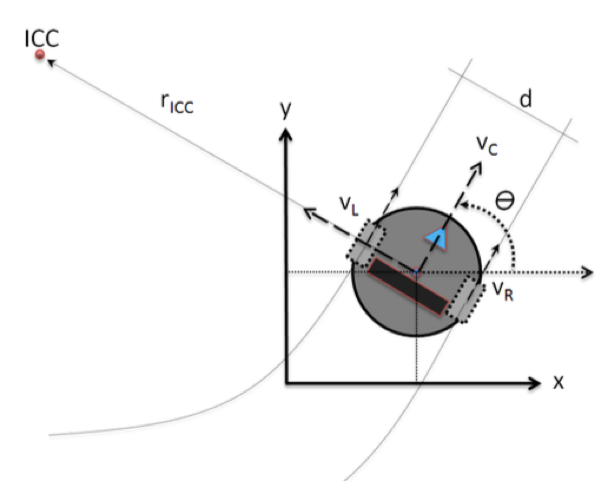

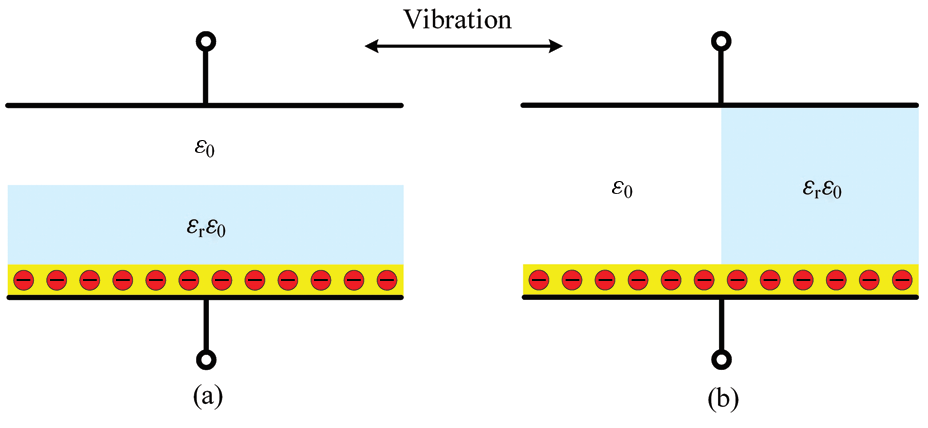

To design a Power Line Communication (PLC) system with a low bit error rate (BER), the PLC couplers used must be matched to the power lines carrying the PLC. These impedances change with frequency, applied loads and the length of the power line. Due to accuracy concerns, the impedance value we got from dividing 240v main voltage by main current is not desirable. In order to obtain a precise impedance value so that we can efficiently couple signal to the power line, a new method has been proposed. A signal generator is used to apply a small-valued high frequency signal to the input circuit, then a high-pass filter network is followed to filter out the main lower frequency voltage of 50Hz, by measuring the current and the voltage the impedance is obtained.

Hardware Introduction

Voltage sensor has a configuration of Stage 1 Differential Amplifier Stage 2 Sallen-Key High pass filter Stage 3 Non-inverting amplifier

The first stage is made up of two differential amplifiers. It serves a purpose of improving the system’s immunity to noises and common mode signals. The AD8045 is used because it has a good speed up to 1GHz when the gain is unity and a wide supply voltage range from 3.3v to 12v [11]. Furthermore, two RC high-pass filters are used before each differential amplifier input to reject mains noise. The second stage is Sallen-Key network that can further provide rejection to the mains noise. The third stage is non-inverting amplifiers combined together to give gain improvement. The current sensor has a relatively easier configuration, which is made up of a resistor bank with an impedance of 12.5 Ohms and an isolation transformer.

Optimisation Using AWR

In order to obtain a flat frequency response so that all impedance values measured through the analyser remains in accordance with the true value at all frequencies, circuit optimisation is required. Rather than achieving this process by hand, computer-based software is used for such a purpose. Following is the schematic view of the circuit in AWR, Resistive Coupler and VoltMeter is represented by two schematics. We set the load impedance to be 50 Ohm for the ease of circuit optimisation.

Fig.2 Before and after Optimization

Circuit Design in Altium Designer

Firstly signal from signal generator is amplified and coupled to the Resistive Shunt circuit through an isolation transformer. Current is also measured at this step. Signal then passes through Ideal Amplifier circuit. Then the signal goes through the Sallen-Key network to filter out low frequency part of the signal and measured by a voltage meter. Computer-based software is later used to analyse the result.

Fig.3 Schematic In Altium

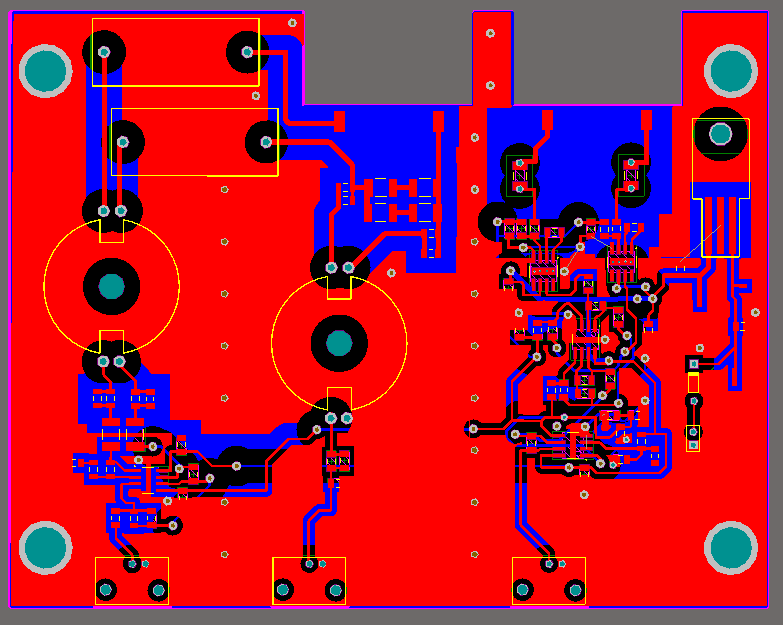

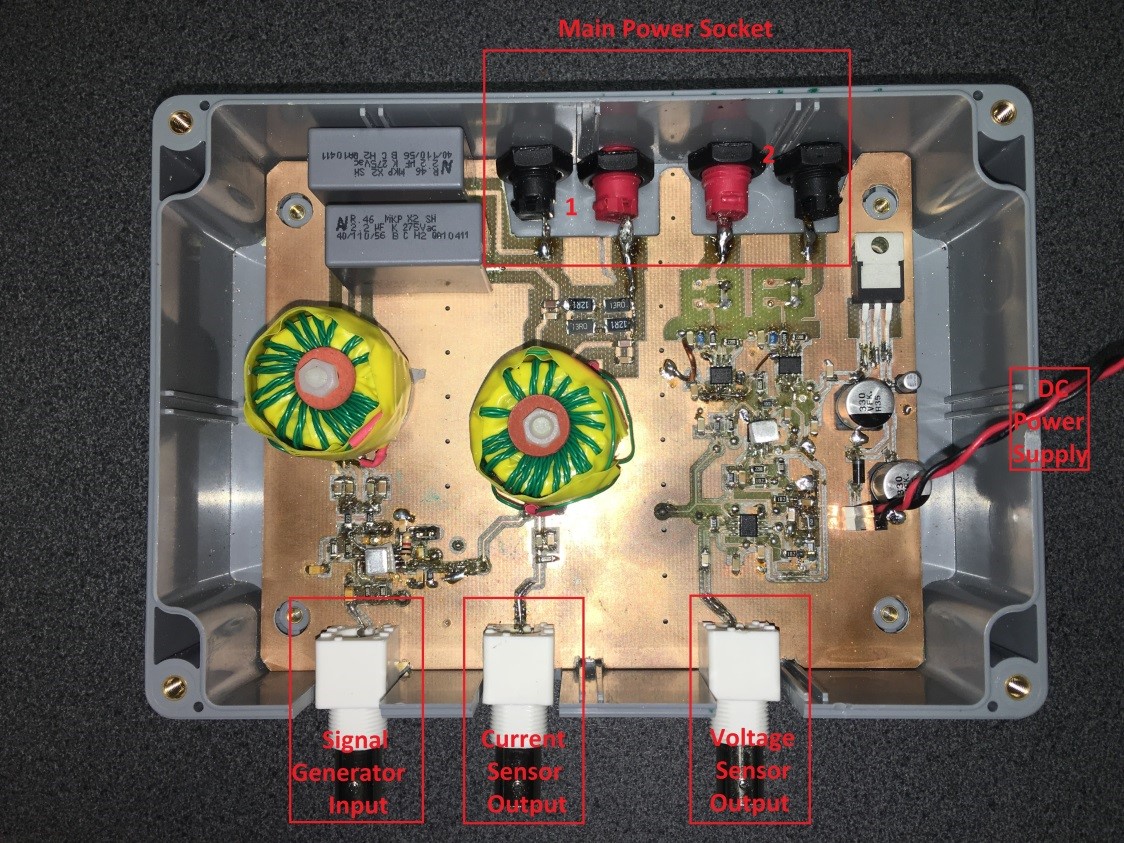

Printed Circuit Board (PCB) Layout and Prototype

A Printed Circuit Board is the physical realization of its related schematic using conductive tracks and pads that are etched from a blank board [12]. Surface mount components (SMD) are used in this project as they are usually small in size and component density can be higher compared with through-hole ones. Furthermore, there will be lower resistance and inductance at the connection points which makes SMD perfect for high frequency uses. As High AC voltage are applied to the top two connectors, high clearance of 3 mm is used for the part where potential high voltage will flow through while 1 mm clearance is used for the rest part. Also components connected to the high mains voltage are carefully selected so that they can handle high voltages.

In practice I found the left amplifier tend to overheat as it needs to provide a power output of roughly 1.5 Watt, and during calibration and measuring it needs to work at its full power output for several minutes, so a good heat sink is needed. Shown above there are metal cubes used for power dissipation on the top of the amplifiers but in practice they are not good, so in the future and in the commercially made products, well designed heat sinks should be used to improve the quality of the board.

Fig.4 PCB layout

Fig.5 Prototype

Transformer

Transformers serve the purpose of isolation from high voltage to the fragile and expensive devices that are connected to the board, but they are usually limited in frequency bandwidth.

A careful selection of transformers that have better frequency performance is essential.

Trifilar winding has a better performance than normal winding.

Fig.6 Transformer Comparison

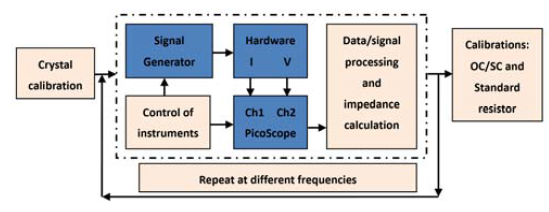

Analyse in Labview

After the manufacture of the hardware, output signal should be analysed through Picoscope together with labview-based software. There are three sections in this software: 1. Signal processing and impedance calculation. 2. The signal generator and Picoscope control. 3. Calculated impedance modification.

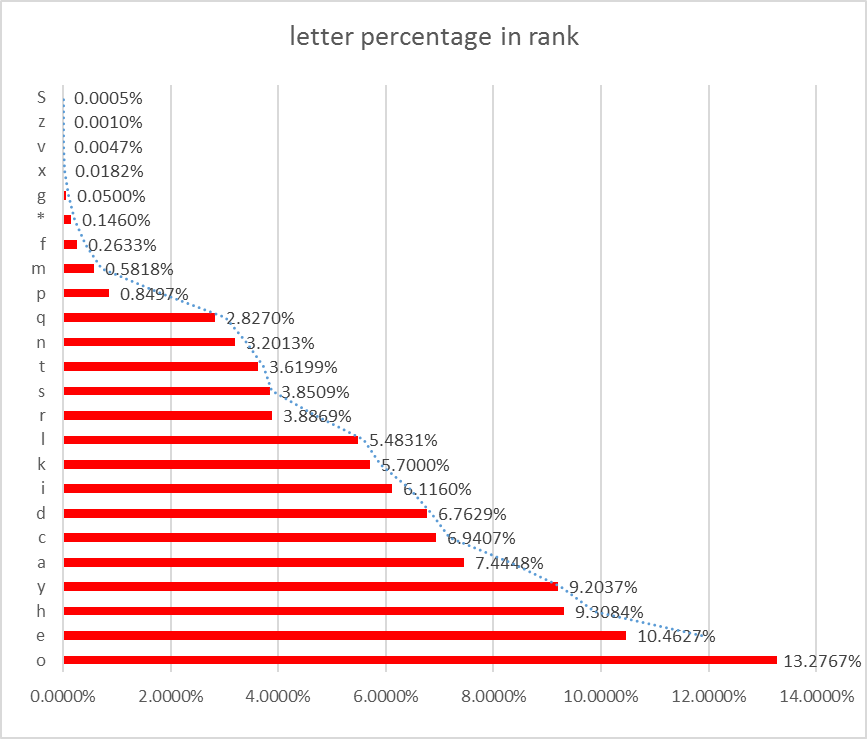

Finally, in order to evaluate the accuracy of the Impedance Analyzer controlled by the software, off-line measurements will be done on different values of resistors.

Thanks to the software developed by Shucheng Zhu and Picoscope of our supervisor Keith, we are capable of analysing the signal with ease.

Fig.7 Labview Interface

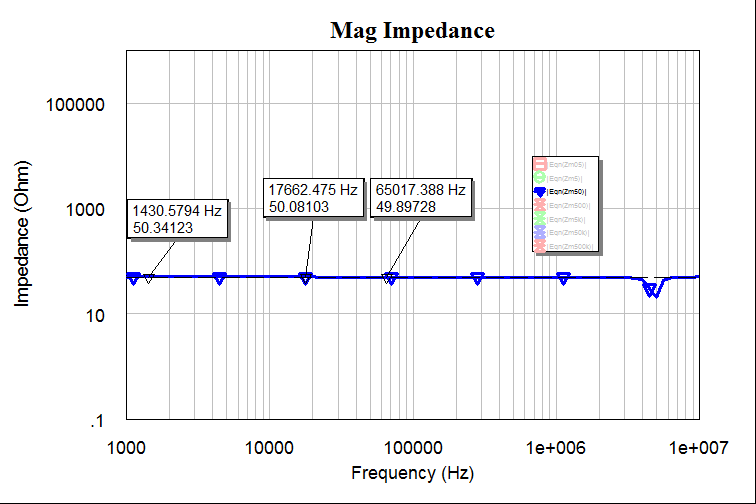

Fig.7 Testing Result

From the above graph we found that the system has a good accuracy from 0.5 Ohms to 4.6K ohms but for the 0.5 Ohms resistor, its measured value is on an uprising tendency, which is due to its inductive structure as it has windings in it.

Conclusions

PLC is an economic and efficient method for information transfer; however power lines provide an extremely noisy environment for data transfer. The impedance of the network mostly depends on network frequency and time, which leads to the mismatch of network impedance and the coupler impedance. The mismatch could cause low data reliability and high Signal-to-noise ratio according to maximum power transfer law. There are existing works related to measuring power line impedance, but they have a poor accuracy and a smaller frequency range. Accuracy is of great importance in the project. The report has presented a computer-based tool for the circuit optimization which is time-saving compared to the traditional hand-based method. After optimization, optimized parameters can be used during the board building phase. We successfully made a fully functional board that can be used to measure the impedance both off-line and on-line. However due to the short time frame we have not gone through the safety evaluation process. Keith’s online measurement is evaluated and we found that impedance of a university room is roughly no more than 30 Ohms. And with this value a suitable modem that can be used to couple information onto the power line can be built.

Future Work

1. As the impedance of the channel depends both on frequency and time, further study on time-varying behaviour of the channel impedance needs to be studied. 2. Transformer Toroids that have better frequency performances as discussed in section 6.1 and smaller size ones should be used to replace the existing ones to minimise the product size and frequency performance. 3. AD8039 with 350MHz speed is better than AD8017 with 160 MHz as used on the board. So in the future AD8039 should be used to replace AD8017. 4. In practice we found certain amplifiers are prone to fail, so a fail-safe circuit can be designed in case when certain part fail, the rest of the components can remain safe. 5. electronic components are prone to fail when temperature rises and to improve heat dissipation, heat sink has been used on our board. Thanks to the help of the workshop faculty who made some small metal cubes, we can put them on the top of vital amplifiers to help power dissipation, but when commercially produced, better and solid heat sinks should be used.

Project Team

Team Members

Haoran Song Qi Yan

Project Supervisors

Nesimi Ertugrul Cornelis Jan Kikkert