Projects:2016s2-245 RFID in a Light Bulb

Contents

project team

Academic Supevisors

Dr. Said Al-Sarawi

Dr. Damith Ranasinghe

team members

ZEYU WANG RAN YE

Acknowledgement

This work is supported by the Department of State Development: Collaboration Path- ways Program - South Australia Government (CPP 39).

Introduction

the development of a permanent power source for self-sustainable wireless sensor networks is essential in order to reduce the maintenance costs and increase the operational time of sensor nodes. Accordingly,over the past decade researchers have actively studied various energy harvesters that generate power form sources such as ambient light, heat, motion, electromagnetic waves and other unused sources of energy. One energy harvester driven by ambient vibrations has attracted special attention because it can easily gain energy form sources of movement such as human physical motion. This project states a liquid-based electrostatic energy harvester that converts the mechanical energy of human-motion-induced vibrations to electrical energy.

Aims

This paper presents a kinetic energy electrostatic harvester with electret as voltage source and liquid-based structure, which converts the mechanical energy in a low working frequency vibration to electrical energy. Moreover, it addresses the discharge issue of electret to improving charge storage stability of electrets in liquid-based environment. Extending from the theoretical research, the prototype of energy harvester is fabricated in proposed structure and is tested its performance in desirable low frequency range. In addition, the high efficiency circuit is necessary in energy conversion that is as important as the capacitor part.

Motivation and Significance

Energy harvesting technologies present a developing self-sustainable power source to replace conventional batteries in portable and low consumable application such as autonomous wireless sensor nodes, low power consumption electronic devices, and implantable medical equipment. As an emerging inexhaustible power source, there is significant developing potential in energy harvesting from ambient energy sources. It is different from piezoelectric harvesters and electromagnetic harvesters, which are mostly designed in a resonant mode and are driven in a relatively high frequency range. For instance, the spring structures are used in energy harvester should overcome their natural frequency to excite the system operation. Therefore, it is difficult to use in a low frequency range. Additionally, the electrets discharge reason limit their usage when it contacts with liquid. The polymer barrier layer is proposed to solve its discharge issue.

Comparing to conventional energy source, energy harvester provides sustainable and clean energy source. Comparing to piezoelectric energy harvester and electromagnetic energy harvester, electrostatic energy harvester has high output voltages; their components are built in low-cost parts, is easy to adjust the coupling coefficient and reaches high coupling coefficients, and increases capacitances through the reduction of size. These advantages are significant in small-scale energy harvester and in low frequency range operation.

The energy harvester needs an initial voltage. The conventional power supply is external power source such as battery and DC power supply, which are inconvenient in portable application, and it will affect the volume of entire energy harvester. And at the same time, the electret replaces these conventional power supply as initial voltage is a crucial part of this energy harvester.

background

Initially, the principle of energy harvester is capacitor. The components of liquid-based energy harvester are composed of two electrodes, which is top and bottom metal plates; a cavity is to store liquid; a Polytetrafluoroethylene (PTFE) film layer is coated on the bottom of cavity. A barrier layer is used to solve electret discharge issue. The electret is used to provide the initial voltage for energy harvester. And the conducting liquid plays a role in changing the way that the arrangement mode of inner capacitors.

In this capacitor, the electret and the covered film are considered as insulating layer. Through changing the liquid state, the inside structure of capacitor is changed when there is an external vibration. When the liquid occasionally contacts with the top insulating layer, the capacitance becomes large due to the air gap is eliminated. To be detailed, the inside structure of capacitor is changed from series capacitance to parallel capacitance. The value of capacitance is expressed as:

Capacitance initial is the minimum capacitance, capacitance excited is the maximum capacitance. ε1 is the permittivity of PTFE electret, ε2 is the permittivity of air, ε_3 is the permittivity of Cellulose Acetate tape. The d1 is the thickness of PTFE, d2 is the thickness of air gap, d3 is the height of liquid, d4 is the thickness of Cellulose Acetate tape. S is the overlay area of the top and bottom plates, Sliquid is the contact area of the conducting liquid and the insulating layer.

As this formula expressed, the electrical energy generation is determined by the capacitance ratio, the maximum capacitance and the electret voltage. As an important part of energy harvester, the electret is the core component of electrostatic energy harvester. It is a dielectric material, which has dipole polarisation or a permanent electric charge. It is similar like magnets that are dipoles. Many materials can be made into electret, most of them are made from synthetic polymers. It can be considered as stable direct current voltage source because there is a huge voltage potential in electret, which is an ideal alternative to DC voltage. However, the potential of electret is difficult to measure precisely at current stage, and it will decrease a lot in large time. The structure of energy harvester, the permittivity of insulating material and the voltage potential of electret are the most important three factors which affect the energy generation. Therefore, this paper will put emphasis on these three factors.

Theory

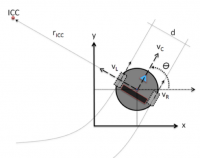

Firstly, comparing to the mechanical motion, the demand of this project is the feature of unpredictable vibrations and in a relatively low frequency range. The piezoelectric devices and electromagnetic devices has high destination for frequency. Therefore, the electrostatic is suitable for meeting this requirement. At the same time, the unpredictable vibration dimension need to be considered. Even though the capacitance can be changed with varying the distance between two plates from relative motion of plates, the weakness is obvious in unpredictable dimensional vibration in random directions. Therefore, the liquid-based electrostatic energy harvester is adopted to solve above problem and improve sensitivity of device.

The structure of energy harvester is a capacitor in factor. According to the capacitance determination equation, C= εS/4πkd, which ε stands for permittivity, S stands for the area over the top and bottom plates, k stands for electrostatic force constant and the d stands for the distance between the top and bottom plates. Therefore, the capacitance can be changed by altering the permittivity of capacitor material, controlling the areas over two plates and adjusting the distance between two plates. This is the fundamental used in this paper to construct the energy harvester.

Moreover, according to the capacitance definition equation, C= (Q)/(U), which Q stands for the quantity of electric charge in plate and U stands for voltage between two plates. Therefore, with the changing of capacitance, and the quantity of electric charge in plate is constant, the voltage between two plates will be changed. Consequently, there is an alternative voltage generated over these two plates, which becomes a power supply to generate power to drive circuit. Hence, it is very important to find an effective way to change the capacitance significantly. The ratio of maximum over minimum is the key factor to affect the output energy power. The larger ratio is, the more power is generated, with the initial voltage unchanging.

The approach that putting sensitive conductive liquid in capacitor is effective to change the distance between two electrode plates. Furthermore, it can change the inner structure in the capacitor. Apart from the distance, the contacting area of the liquid and top plate is changed as well, obviously, the capacitor is changed from in series to in parallel. It can bring a larger capacitance when the conductive liquid moves from horizontal direction to vertical direction contacting with the top plates.

Besides the distance between two plates and contacting area of inner structure, the relative permittivity of material of each component is important as well. The components involve in this capacitor respectively are electret and insulating layer. The relative permittivity of material should be as larger as possible. The standard of choosing the material of insulating layer and side wall, there are some characteristic should be taken into consideration, such as, friction coefficient, adhesiveness, electrical insulating property, toxicity, corrosion resistance. In particularly, the low friction coefficient and low adhesiveness is essential for the sensitivity of capacitor and that is one of key factors to ensure feasibility of capacitor in low frequency range.

Secondly, the electret is used in this project to replace traditional voltage source. Electret cannot be removed from current like battery, however, it can provide a stable voltage, and it is therefore a good dc voltage source. In order to improve the portability of energy harvester, the simpler structure is necessary. The initial voltage could be provided by electret instead of external power supply.

The electret is made from some insulating material. It is like magnets to some extent and it has a permanent electric charge and can generate electrostatic field. However, there is an issue about the utility of electret that is the static electricity over the surface will discharge and result in the disappearance of surface potential at the same time. To be detailed, when the conducting liquid contacts directly with electret, it can discharge and cause the lifespan of energy harvester shorten significantly. Therefore, the polymer barrier layer is deposited between conducting liquid and electret surface can effectively protect the discharge conduction, and increase the lifespan to guarantee the charge storage stability and the performance of energy harvester.

Because of the uncertainty and uncontrollability during the charging process of the electret, the characteristic of electret cannot be specified. Under this situation, the outcome of experimental is instable. Therefore, the effect of instability should be taken into consideration.

Finally, the choice of conductive liquid is gallium (Ga). It is one kind of liquid metal that the melting point is under 29.8℃, the others are mercury that is the only liquid metal under room temperature and pressure and caesium that the melting point is under 28.4℃. even though the melting point of gallium is highest among these metals, the mercury and caesium are both toxic. Therefore, the gallium is the safest choice.

Linear technology company et al (2010) [5] proposed LTC3588-1 is an ultralow current power supply that is designed for energy harvesting. LTC3588 can interface directly with AC power source, rectify AC voltage waveform and store harvested energy. LTC3588 have lots of features which necessary for my project. The features are shown as follow: 1. 950nA input quiescent current 2. 450nA input quiescent current in UVLO 3. The lowest operating voltage is 2.7V and highest operating voltage is 20V (even if the input voltage is higher than 20V) 4. Low-loss full-wave bridge rectifier 5. The limitation of output currents up to 100mA 6. Four choices output voltage of 1.8V, 2.5V, 3.3V, 3.6V 7. High efficiency hysteretic buck DC/DC 8. Input protective shunt up to 25mA pull-down at Vin>=20V 9. Small size 10-lead MSE packages 1.1 Pin functions PZ1 and PZ2 (Pin1 Pin2): these two pins are input connection for electrostatic energy harvester element or another AC source. CAP (Pin3): it is an internal rail referenced to Vin, which will serve buck PMOS switch as gate drive. One 1uf capacitor should be connected between CAP and Vin. CAP pin should not be used as the external system rail. VIN (Pin4): rectified input voltage comes out from this pin. A capacitor be suggested to connect this pin as an energy reservoir and a supply for the buck regulator meanwhile the Vin voltage is clamped to 20V. SW (Pin5): it is switch pin for the buck switching regulator. A 10uh inductor is recommended to connect from SW to Vout. Vout (Pin6): A sense pin which is used to monitor the output voltage Vin2 (Pin7): internal low voltage rail to serve as gate drive for buck NMOS switch. The voltage that come from Vin2 is regarded as a logic high rail for output voltage. A 4.7UF capacitor should be putted between Vin2 and GND. D1 and D2 (Pin8 Pin9): output voltage selection Bit. GND (exposed pad pin 11): ground.

Theory

In this paper, through different ways to assist develop the energy harvester, the theoretical approach of capacitor, the investigation of each component of material, the charging method of electret, design software and the stepper motor will be stated below.

The theoretical approach of capacitor

The energy harvester has many aspects of characteristic perform, and the varying processing of inner capacitor is complex. Therefore, the process is simplified to calculate the consequences. When the capacitor moves by external motions, the permittivity distribution varies within the capacitor structure cause a large capacitance variation, the large capacitance variation is considered as the capacitance ratio which is equal to maximum capacitance over minimum capacitance (C_ratio=C_max/C_min ). The capacitance ratio concept is more than important in energy harvesting because it can be used in analysing varying charge volume, and in generated electrical energy. The energy power of capacitor commonly is E=1/2 CV^2. Because of varying capacitance, the output power of energy harvester is ∆E=1/2 (C_ratio-1) C_max V^2 in discharge process. To assume the operation frequency is 1 Hz, there are 3.31µw output power generated in one cycle.

The investigation of each component of material

The material of components is as well as important in design. Because the different material has different characteristic and different state of art, the material chosen needs to consider the cost and to guarantee the perform of capacitor. There are four kinds of material is chosen in this capacitor, namely, cellulose acetate tape, PTFE and Copper (Cu). The PTFE is material of the cavity, cellulose acetate tape is used as polymer barrier, PTFE is the material for electret, and the Cu is considered as the metal plates to the electrode.

PTFE commonly referred to as non-stick coating or easy to clean material. This material has the acid alkali resistance of various organic solvent resistance characteristics, almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, low coefficient of friction of it, so can make lubrication, also become the ideal of easy to clean the pipe inner coating.

It has excellent chemical stability, corrosion resistance, corrosion resistance in the world today is one of the best materials. In addition, PTFE has high sealing lubrication is not sticky electric insulation, good anti-aging ability and excellent heat resistance.

Cellulose acetate is a kind of man-made substance which is derived from an organic compound in nature named cellulose. It is recognised as the most common organic compound. And cellulose is a biodegradable and renewable substance. It is a cheap source and commonly is used in many manufacturing fields. The material is used in this paper is cellulose acetate tape, which is a production made from cellulose. The permittivity of cellulose is 3.6-7.0, the breakdown voltage of it is extremely high, and the thickness of tape is around 40 microns. Consequently, it is an easy-obtained insulating material with an ideal thickness.

Therefore, cellulose acetate constitutes as the polymer barrier layer to significantly improve charge storage stability of electrets when conducting liquid directly contacts with electret interface.

Gallium (Ga) is a kind of liquid metal and non- toxic, which is considered as an ideal conductive material but the melting point of gallium is 29.8℃. thinking of the safety, gallium is chosen as the conductive material instead of mercury.

The charging method of electret

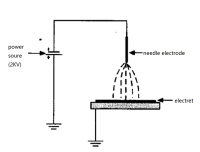

Corona charging method is one of the most widely used method in making electret. It has the advantage that the charging voltages are controllable in corona charging process. In addition, the surface charge electret can be easily obtained in room temperature.

Corona polar method is that the needle electrode which is added with high voltage discharges the corona. A large number of charged ions produced by corona discharge are driven to the anode at high speed under the applied electric field. The sample near the anode will be charged by charged ions and charged by the method. When the surface of the sample when accumulated to a layer of charged ions, the charged ions and the surface of the sample will undergo charge and energy transfer. Under certain conditions, the charge exchange between charged ions and sample surfaces achieves dynamic equilibrium. However, after this method of charging, the surface charge of the electret exhibits a bell-shaped distribution that the central surface potential of the electret is significantly higher than the surrounding surface potential.

The theory of circuit '

Internal bridge rectifier When the current flow into the LTC3588 it will firstly pass a low cost internal full wave bridge rectifier which is accessible via PZ1 and PZ2. The bridge has a total drop of about 400Mv with around 10μA current. After that the input voltage will be rectifier and charge will be stored into input voltage capacitor. if the input voltage is over 20V the voltage will be clamped into 20V

Under-voltage lockout There are two thresholds of UVLO. One is rising threshold another is falling threshold. When the voltage on Vin is higher than the rising threshold of UVLO the UVLO will send signal to buck converter and it will be enabled. After that the charge is transferred from the input capacitor to the output capacitor. the falling threshold approximately 300mV above the selected regulated. When charges are transferred to the output capacitor the voltage of input capacitor is depleted below the UVLO falling threshold. The buck converter is disable and then a low current in UVLO allows energy to accumulate on the input capacitor.

Internal rail generation There are two internal rails CAP and Vin2 which come from Vin and are used to drive high side PMOS and low side NMOS of the buck converter, respectively. In addition, the Vin2 rail serves as a logic high for D1 and D0 pin which are in charge of selection of output voltage. The value of Vin2 is 4.8V higher than GND and the CAP rail is 4.8V less than Vin which can provide a 4.8V voltage to drive the comparator.

Buck operation A hysteretic voltage algorithm is used to control the output through internal feedback from the Vout sense pin. The output capacitor is charged by an inductor and the value of the voltage on the capacitor will be a little bit higher than the regulation point. This is achieved by ramping the current of inductor up to 260mA through an internal PMOS switch and then ramping it down to 0mA through an internal NMOS switch. This approach is efficiently. As long as the input voltage falls below the UVLO falling threshold, the buck converter will stop work and is waiting for input voltage increase above the UVLO rising threshold. During this period, a current which will be less than 100nA will be loaded on the output voltage. When the voltage on output capacitor reaches the regulation voltage the converter come into a sleep state which will monitor the output voltage by a sleep comparator which has a bandgap reference. The voltage is used for sleep comparator comes from Vin sense pin and the voltage is divided by two series resistors. There is one variable resistor. when the connection of D0 and D1 changed the variable resistor will also change to address the different requirement of sleep state comparator and PGOOD comparator. When the buck converter is working under this mode the current is provided by the output capacitor. As soon as the voltage on output capacitor falls below the regulation the cycle will repeat. This hysteretic approach of regulated output voltage decreases the losses when the PMOS and NMOS is switching and maintains an output voltage in a low load.

Sometimes, when the sleep comparator send signal to buck control that the voltage of output capacitor has reached the sleep threshold the buck converter may be in the middle cycle, which means the current still flowing through the inductor. Usually, PMOS and NMOS switches would turn off meanwhile the current in the inductor will be depleted into zero by the NMOS body diode. However, the LTC3588 will keep the NMOS switch on in this period to prevent losses which would occur in the diode.

Although the current while the buck is switching is greater than the sleep current it is still a small party of the inductor current which will result in high efficiency. The buck converter will work only when the input capacitor has accumulated enough energy meanwhile the period of time that converter transfers energy to the output capacitor is much less than the time that input capacitor harvests energy. If the current in the buck is averaged over a long period time the total average is low

Power good comparator The power good comparator produces a logic high voltage which referenced to Vout on the PGOOD pin. When the converter reaches the sleep threshold of the selected Vout, signalling that the output is in regulation. Power good comparator pin will be logic high until Vout falls to 92% of the selected voltage, which allow output voltage can be used even if the input voltage is lost in short period. Figure 19 shows an example of Vout=3.6V and no load. As we can see from figure at t=75s Vin starts to decrease. Even if Vin crosses UVLO falling PGOOD still remains high until Vout decreases to 92% of the selected output voltage.

The input of D1/D0 can be switch between the four outputs option. There is one special phenomenon when the output voltage is set to new voltage with a logic low PGOOD, PGOOD will transit low until output voltage reach the new regulation point

Results

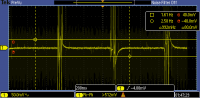

When there is no barrier layer for electret, the output voltage of energy harvester is extremely instable, it can achieve maximum voltage which is 5V from time to time. And due to the discharge issue of electret, it is apparent that the attenuation of output voltage starting to test. the electret can operate just for a while. Even though the output voltage is good, this method cannot be adopted. Therefore, the discharge issue is an obstacle that the energy harvester is in practice.

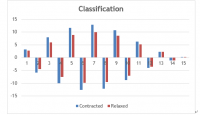

Therefore, the cellulose acetate tape is put on the electret as the insulating layer to protect the electret from discharging. Firstly, the energy harvester is mounted on the stepper motor to test it under 10 Hz which is the highest frequency of our requirement. Under the opened-circuit, the energy harvester is directly connected with oscilloscope. The energy harvester moves in tilting direction. The maximum forward output voltage, which is shown, is 40mV, ant the maximum output backward voltage is -40mV. Ideally, the maximum forward output voltage should equal to the maximum backward output voltage. However,

Under a random vibration with hand-shaking, the maximum output voltage can achieve 1.9V which is the highest output voltage that can be generated by this energy harvester with barrier layer. However, with the uncertainty of hand-shaking, the output voltage is instable. And I still want to figure out how I can keep generating and the reason that the output voltage is different.

Therefore, in another condition, under the random vibration with slower hand-shaking, and try to control the range of vibration, there is a lower output voltage. The reason that the output voltage is inconsistent, because there are many factors so that it cannot be quantized, and be measured.

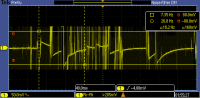

The selected output voltage of LTC3588 is 1.8V and because there is noise in our testing environment which was shown in above figure the recorded result is acceptable. But the fluctuation should not appear in the result. The ideal result should like a straight line. In order to explore with this problem, different resistors were used to connect output to check what will happen in the voltage. After a few group test, the regular variance is that the maximum will not change but the minimum is pulled down deeper. when the voltage is more than 20V the output voltage will have negative part which is obvious wrong. Furthermore, according to datasheet, some resistor is connected to PZ1 and PZ2 pin to limit the current in some application. Because the current which comes from voltage generator is unknow the multimeter is used to test the current of voltage generator.

However, the absolute maximum ratings of Ipz1 and Ipz2 is 0.05A which is less than all of current which comes from voltage generator. Besides above limitation, the absolute maximum continuous current is 0.005A therefore the protective resistor is necessary to connect with input pin. When the current limiting resistor whose value is approximate 800Ω is series to the input pin, the output voltage waveform is a straight line which is 1.84V. whatever the input voltage is the output will be stable and as same as the

The MSP430 microchip is the one which is our propose to drive. The working current and voltage of this chip is 1.8V and 230μA therefore the alternative resistor of this chip is equal to voltage divided by current. The 8KΩ resistor will be used to substitute the microchip. When the 10V peak to peak sine waveform input signal is putted into the PZ1 and PZ2 pin the output voltage is shown in figure 30.

The maximum voltage from output is 1.96V and minimum voltage is 1.04V. the output voltage dropped from half within a 200ms period. the reason of this phenomenon is output resistor was depleting the energy so output voltage will drop and pull up again due to new energy. when the input voltage was increased from 10V to 20V, the minimum voltage increased a little and the duty cycle of voltage increased slightly. The number of variation between maximum and minimum of output voltage from 0.68V to 1.04V. besides the voltage, if we increased the frequency of the input voltage the output will change in same way when we changed the input voltage but it isn’t apparent.

Conclusion

In this paper, a liquid-based electrostatic energy harvester with electret in low frequency and movement in random directions is designed and investigated. Under various environments of non-periodic ambient motion. The designed electrostatic energy harvester produces a capacitance variation ratio of 41.25, and the maximum power is calculated theoretically of 3.31µw. The output voltage is 40mV when energy harvester is mounted on stepper motor, the output voltage is 500mV with lower speed and the maximum output voltage can achieve 1.9V with high speed hand shaking. in addition, the cellulose acetate barrier layer is presented in this paper to address the discharge issue of electret which affects the performance significantly in liquid-based electret kinetic energy harvester and makes it stably operates. The electret energy harvester can achieve a good performance and show promising future as a sustainable energy generation for portable devices.

The designed circuit has the capacity to transfer the most of electrostatic energy into electricity. The size of circuit is pretty small which is only 15.75mm×10mm. The advantage of this circuit is it can produce stable output voltage and can efficiently transfer energy into capacitor. The disadvantage of this circuit is the initial voltage doesn’t match the energy harvester which only can produce 1.9V.

Project management

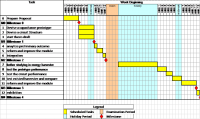

Work Breakdown

The content of project consists of two parts which one is capacitor prototype and another is circuit structure. The key task in first stage is to analyse and device the capacitor prototype and circuit structure. However, the function of circuit is to transfer and store the outcome power of capacitor in circuit. In addition, the energy stored in circuit can be considered as an energy supplier. The output power of capacitor is essential data for circuit design. Therefore, the analysis of capacitor is important fundamental for further studying.

Timeline

The original plan is designed to manage time plan, and control and limit the process of project. However, there is some difference in project execution and original plan, because the new knowledge gap generated or the new challenge occurred. When these difficulties met in process, the original plan might need to be delayed or changed to meet new requirements.

Task allocation

The energy harvester is allocated into two parts which one is capacitor and another charge pump. These two parts is importantly equally. I am responsible for capacitor part which need to analyse and design capacitor, to build and test a prototype to compare to presented electromagnetic energy harvester. and my team mate is responsible for charge pump circuit.

Risk management

Most of this process is no especially risk. However, the conducting liquid chosen in this project is DMF. DMF has Health hazard which has invasive ways: inhalation, eat, percutaneous absorption. It has Acute toxicity, DMF is Inhaled 30 ~ 60 PPM, gastrointestinal symptoms, liver meritorious service is abnormal, there are jaundice, uric bravery former increases, proteinuria; Inhaled 10 ~ 20 PPM (sometimes 30 PPM), headache, loss of appetite, nausea, hepatic function and electrocardiogram (ecg) is normal; Inhaled 49 mg/m3 x 5.1 ~ 3 years, god failure syndrome, low blood pressure, liver function change. In addition, its dangerous characteristic: flammable, high heat, open flame or contact with oxidant, has caused the risk of burning explosion. It can react with sulfuric acid, fuming nitric acid fierce, even an explosion. And halide severe reactions can occur (such as carbon tetrachloride). Therefore, it should take the right protective measures. if it leaks few: with sand or other incombustible material adsorption or absorption. It can also use a lot of water to rinse, wash water diluted into the wastewater system. Additionally, eye protection: wear chemical safety goggles; Body protection: wear chemical protective clothing; Hand protection: wear rubber gloves; Other: no smoking on site. Take shower and change clothes after work.

Management Strategy

The management strategies used in whole process of project is the project scope management which is used to define, to validate and to control the project, the project time management which is used to plan and manage the project schedule, the risk management which is to protect the safety of facilities and personnel and the project communication management which is vital in group communication and to promote effectively operation of project.

References

[1] A. Karami, D. Galayko and P. Basset, "A Novel Characterization Method for Accurate Lumped Parameter Modeling of Electret Electrostatic Vibration Energy Harvesters", IEEE Electron Device Letters, vol. 38, no. 5, pp. 665-668, 2017.

[2] B. C. Yen and J. H. Lang, “A variable capacitance vibration-to-electric energy harvester”, IEEE Trans. Circuits Syst., 53, pp. 288-295, 2006.

[3] D. Choi, C. Han, H. Kim and J. Yoon, "Liquid-based electrostatic energy harvester with high sensitivity to human physical motion", Smart Materials and Structures, vol. 20, no. 12, Art. No. 125012, 2011.

[4] D. Kim, S. Yu, B. Kang and K. Yun, "Liquid-based electrostatic energy harvester using rotational motion of ferrofluid droplets", Transducers 2015, Anchorage, Alaska, USA, no. 21-25, pp. 59-61, 2015.

[5] Dassault Systèmes SolidWorks Corp, "Product", Solidworks, 2016. [Online]. Available: http://www.solidworks.com/sw/3d-cad-design-software.html. [Accessed: 18- Oct- 2016].

[6] F. Khan and M. Qadir, "State-of-the-art in vibration-based electrostatic energy harvesting", Journal of Micromechanics and Microengineering, vol. 26, no. 10, Art. No. 103001, 2016.

[7] H. Chen, Y. Song, M. Han, B. Yu, X. Cheng, X. Chen, D. Chen and H. Zhang, "Liquid metal droplet based tube-shaped electrostatic energy harvester", MEMS 2016, Shanghai, CHINA, no. 24-28, pp. 1253-1255, 2016.

[8] H. Okamoto, T. Suzuki, K. Mori, Z. Cao, T. Onuki and H. Kuwano, "The advantages and potential of electret-based vibration-driven micro energy harvesters", International Journal of Energy Research, vol. 33, no. 13, pp. 1180-1190, 2009.

[9] Kinetron. (2016, Oct. 4). MG4.0H datasheet. [Online]. Available: http://www.kinetron.nl.

[10] L. Bu, X. Wu, X. Wang and L. Liu, "Liquid encapsulated electrostatic energy harvester for low-frequency vibrations", Journal of Intelligent Material Systems and Structures, vol. 24, no. 1, pp. 61-69, 2012.

[11] L. Bu, X. Wu, X. Wang and L. Liu, "A novel vibration energy harvester of polytetrafluoroethylene bulk electrets and double side charging structure", Nanotechnology and Precision Engineering, vol. 6, no. 11, pp. 497-502, 2013.

[12] L. Bu, H. Xu, B. Xu and L. Song, "Micro-fabricated Liquid Encapsulated Energy Harvester with Polymer Barrier Layer as Liquid Electret Interface", Journal of Physics, vol. 557, p. 012-036, 2014.

[13] M. Han, B. Yu, G. Qiu, H. Chen, Z. Su, M. Shi, B. Meng, X. Cheng and H. Zhang, "Electrification based devices with encapsulated liquid for energy harvesting, multifunctional sensing, and self-powered visualized detection", J. Mater. Chem. A, vol. 3, no. 14, pp. 7382-7388, 2015.

[14] P. Green, E. Papatheou and N. Sims, "Energy harvesting from human motion: an evaluation of current nonlinear energy harvesting solutions", Journal of Physics: Conference Series, vol. 382, p. 012-023, 2012.

[15] P. Mitcheson, E. Yeatman, G. Rao, A. Holmes and T. Green, "Energy Harvesting from Human and Machine Motion for Wireless Electronic Devices", Proceedings of the IEEE, vol. 96, no. 9, pp. 1457-1486, 2008.

[16] S. Boisseau, G. Despesse and B. Ahmed Seddik, "Electrostatic conversion for vibration energy harvesting ", Small-Scale Energy Harvesting, Intech, pp. 1-39, 2012.

[17] S.-M. Jung and K.-S. Yun, “Energy-harvesting device with mechanical frequency-up conversion mechanism for increased power efficiency and wideband operation”, Appl. Phys. Lett., 96, Art. No. 111906, 2010.

[18] Y. Suzuki, "Electret based vibration energy harvester for sensor network", Transducer, pp. 43-46, 2015.

[19] T. Galchev, K. Hanseup, K. Najafi, “Micro power generator for harvesting low-frequency and nonperiodic vibrations”, J. Micromech. Microeng, vol. 20, no. 4, pp. 852–866, 2011.

[20] W. stark and R. danz, "Time dependence of electret potential during cuurent limited charging in a small air gap and corona charging", IEEE, pp. 261-266, 1991.

[21] Z. Yang, E. Halvorsen and T. Dong, "Electrostatic Energy Harvester Employing Conductive Droplet and Thin-Film Electret", Journal of Microelectromechanical Systems, vol. 23, no. 2, pp. 315-323, 2014.