Difference between revisions of "Projects:2019s1-131 Fuel Cell Hybrid Vehicle: Energy Management and AI-Enable Intelligent Control"

(→Energy Management Strategy Design) |

(→Energy Management Strategy Design) |

||

| Line 79: | Line 79: | ||

[[File:MDP Bellman.png|500px|center|frameless]] | [[File:MDP Bellman.png|500px|center|frameless]] | ||

| + | |||

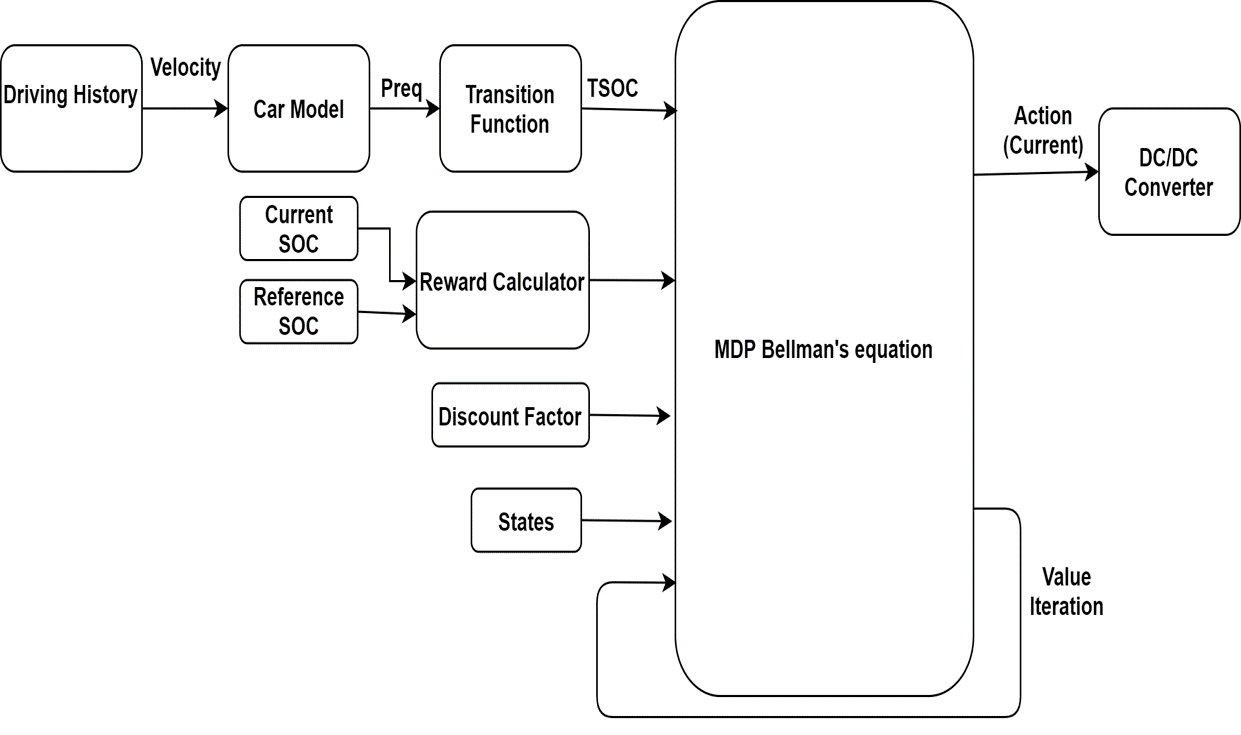

| + | The optimisation problem is solved by using Markov Decision Process. Since we have driving history from the past, we are using Markov Chain on these set of data to get a transition matrix of the vehicle's power demand. This transition matrix shows the probability of each power demand changes to other power demand. Then, since we are using Markov Chain we proceed to model the optimisation problem by using Markov Decision Process. This is because we are using the probability matrix of driving history to determine the optimal control to regulate the power flow between fuel cell and battery. Markov Decision Process is an algorithm to determine an optimal control based of state of the vehicle and reward function. We determine the state of the vehicle as SoC of the battery. While we determine the reward function as cost function of fuel consumption and SoC deviation from a reference. | ||

| + | |||

| + | Then, we solve the optimisation problem by using Bellman equation based on the figure above. The input is transition matrix of battery SoC, reward function, discount factor and states of the vehicle. The output is optimal current from the fuel cell which will be sent its signal to the DC-DC converter. | ||

=== '''Battery Management System Design''' === | === '''Battery Management System Design''' === | ||

Revision as of 18:57, 29 October 2019

Contents

Project team

Project members

- Loqman Al Hakim Aripin

- Jan Zhen Pang

- Tsz Yee Ha

Supervisors

- Prof. Cheng Chew Lim

- Prof. Peng Shi

Technical advisor

- Mr. Di Shen

Introduction

Why Fuel Cell Hybrid Vehicle?

Fuel Cell Hybrid Vehicle (FCHV) uses hydrogen gas to fuel the vehicle. Compared to a conventional vehicle, this vehicle produces zero-emission since it only emits water vapour. This is one of the solutions for an eco-friendly vehicle. In addition, fuel cell hybrid vehicle does not need to charge the battery since it capable to maintain the battery SoC at a certain level. This has the advantages over the pure electric vehicle which need to take a long period of time to fully charge the battery.

In order to maintain the State of Charge (SoC) of the battery, the energy flow inside the FCHV needs to be regulated. This motivates the project to develop a Power Control Unit (PCU) to regulate the energy flow between fuel cell stack (FCS) and the battery.

However, the SoC of a battery is practically not observable. This requires the team to develop a Battery Management Strategy to estimate the SoC of the battery.

Aims

The aims of this project are:

- Develop a PCU for the Energy Management Strategy where it capable to:

- To control and regulate the power flow from two power sources (FCS and battery) of the FCHV

- Minimise the total hydrogen fuel consumption

- Maintain the SoC of the battery

- To consider and observe the power density and the energy density to achieve optimal energy storage for the FCHV

- Develop a Battery Management System to estimate the SoC of the battery

- Develop a fully functional simulator to analyse the performance of the PCU

Background

Fuel Cell Hybrid Vehicle

In recent years, the development of hybrid vehicles increases dramatically where hybrid electric vehicles (HEVs) are widely used throughout the world. The term hybrid vehicle generally means that the vehicle uses one or more different form of power sources to power up the vehicle. In this project, we will focus on Fuel Cell Hybrid Vehicle (FCHV), where it uses hydrogen gas as fuel to power the vehicle. In addition, the battery pack is also added to act as energy storage and provide sufficient energy to the vehicle when necessary.

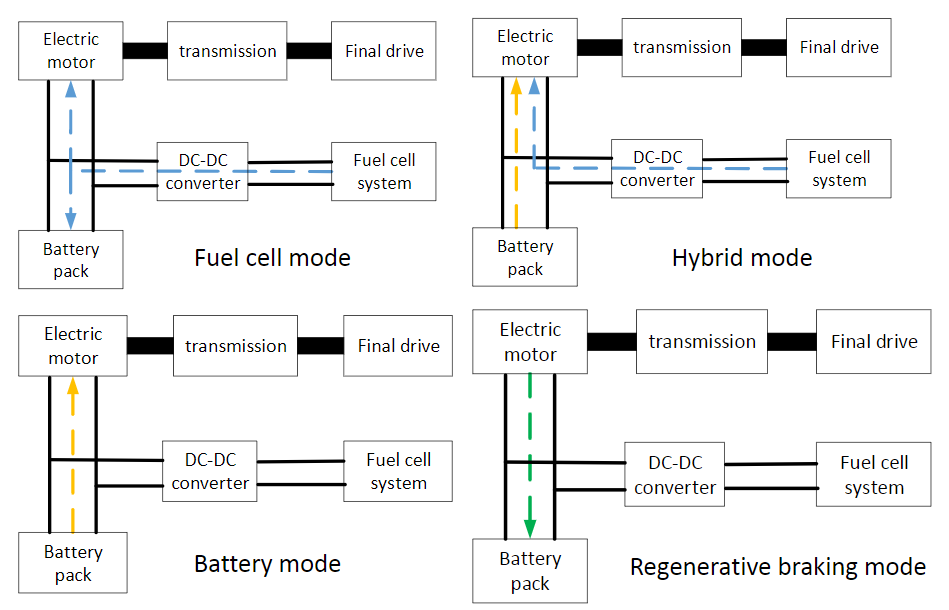

Moreover, FCHV consists of several modes during operation such as fuel cell mode, hybrid mode, battery mode and regenerative braking mode which is shown in Figure 1 below. Firstly, fuel cell mode power up the vehicle while charging the battery by just using the fuel cell stack. During the battery mode, the only power source of the vehicle is battery. The hybrid mode made up of two different power sources (FCS and battery) supplying power to drive the vehicle. Lastly regenerative braking mode supplies power back to the battery pack by converting the kinetic energy of the vehicle into electric energy.

Based on Figure 1, the FCHV mainly uses the combination of the FCS, battery pack, motor driver and DC-DC converter. A PCU is needed in order to regulate and control multiple power sources of the FCHV.

Methodology

Power Plant

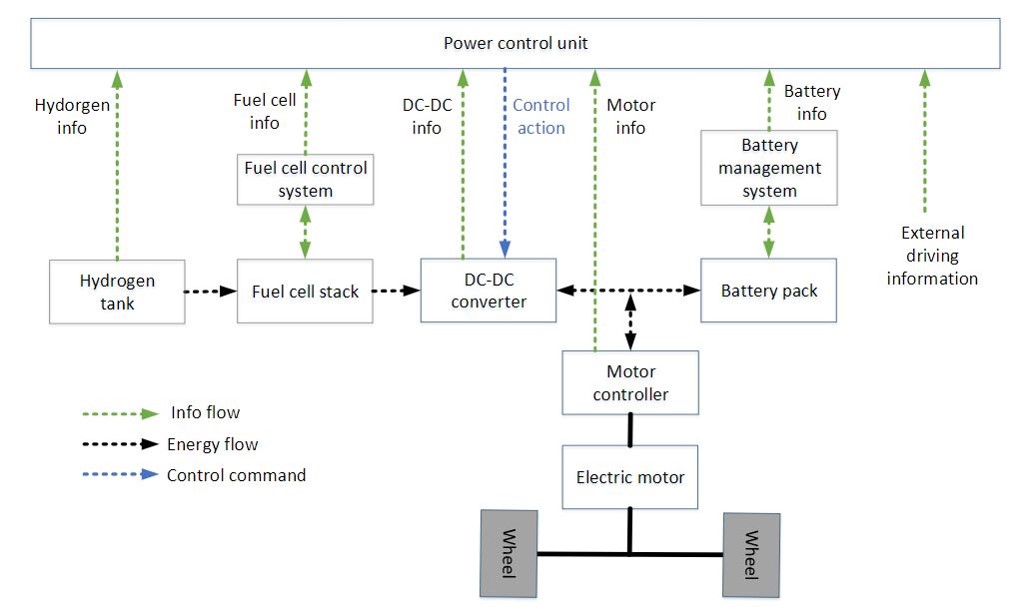

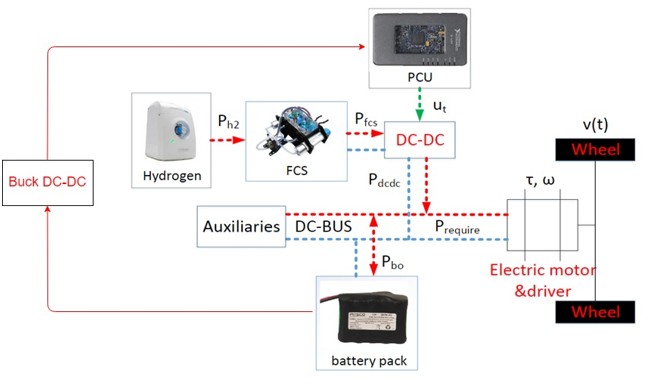

FCHV system mainly uses the combination of PEM fuel cell stack, DC-DC converter, PCU, 24V Nickel Metal Battery Pack, Electric Motor and Motor Driver. DC-DC converter plays an important role in the powerplant of the FCHV because DC-DC converter can control and regulate the energy flow of the FCHV. On top of that, the DC-DC converter receives the signal from the PCU to change the desired output requested by the PCU. Based on the Figure below [1], all the information of the powerplant is sent to the PCU and PCU will send a control signal action to the DC-DC converter. Therefore, an energy management system is required to regulate the energy flow.

The specification of each of the components in the powerplant of the FCHV is listed as shown below.

Fuel Cell Stack

- Type of Fuel Cells: PEM

- Number of Cells: 14 cells

- Rated Power: 30W

- Performance: 8.4V/3.6A

DC-DC Converter

- Input Range: 8-14V

- Output Range: 15-25V, 1.2-2A

Battery Pack

- Type: Nickel Metal

- Specification: 24V 3000mAh

The system block diagram of the energy flow of the FCHV to demonstrate how the energy flow between the power plant in the vehicle.

The total required power formulation can be defined as below:

where Pfs is the output power of the Fuel Cell Stack, Pbo denotes the output power from the battery, PAux denotes the auxiliarites's power, PDC-DC denotes the power output of the DC-DC converter and Prequired denotes the power requried need from the vehicle.

High Level Design

Energy Management Strategy Design

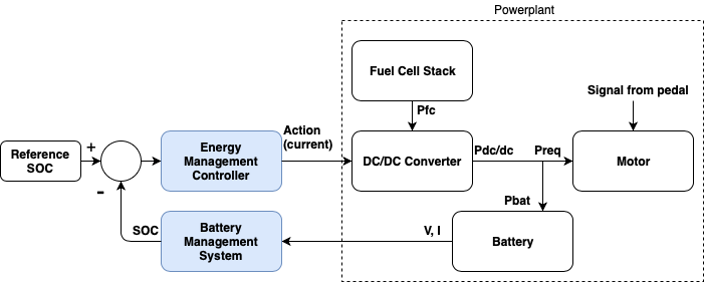

The optimisation problem is solved by using Markov Decision Process. Since we have driving history from the past, we are using Markov Chain on these set of data to get a transition matrix of the vehicle's power demand. This transition matrix shows the probability of each power demand changes to other power demand. Then, since we are using Markov Chain we proceed to model the optimisation problem by using Markov Decision Process. This is because we are using the probability matrix of driving history to determine the optimal control to regulate the power flow between fuel cell and battery. Markov Decision Process is an algorithm to determine an optimal control based of state of the vehicle and reward function. We determine the state of the vehicle as SoC of the battery. While we determine the reward function as cost function of fuel consumption and SoC deviation from a reference.

Then, we solve the optimisation problem by using Bellman equation based on the figure above. The input is transition matrix of battery SoC, reward function, discount factor and states of the vehicle. The output is optimal current from the fuel cell which will be sent its signal to the DC-DC converter.

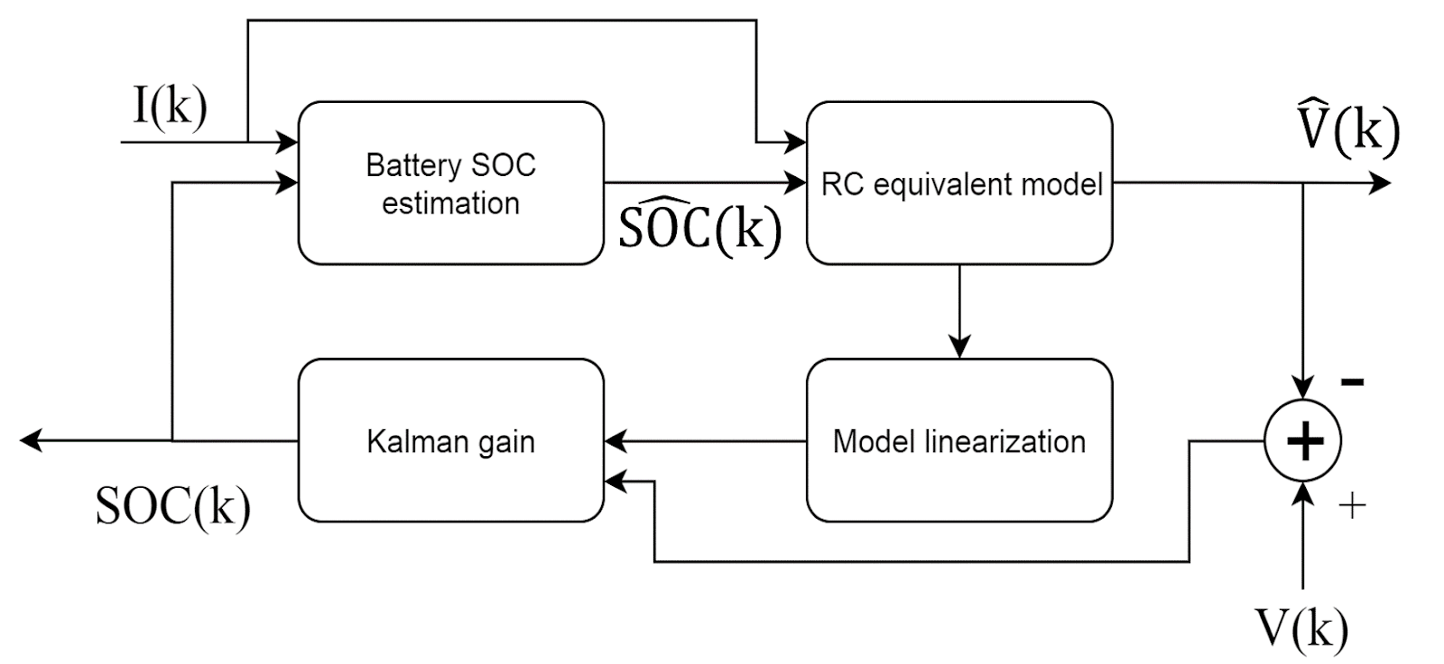

Battery Management System Design

Simulation

Power Plant

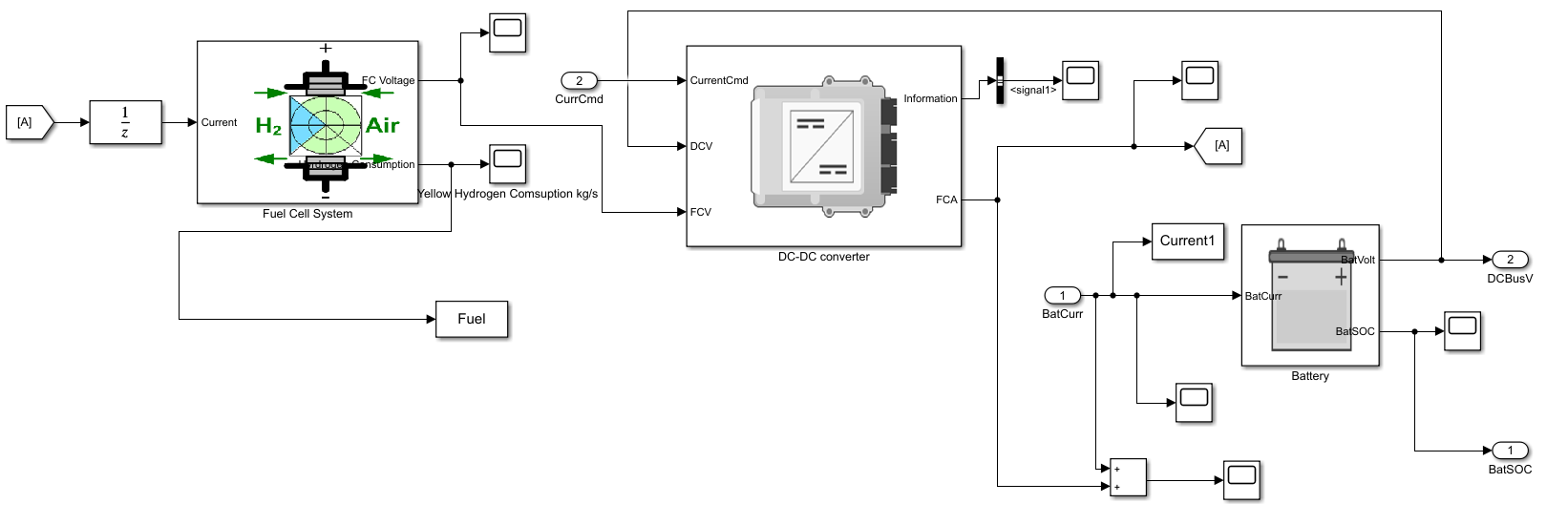

The powerplant design simulation using MATLAB/Simulink is shown below:

The Power Plant consists of Fuel cell, battery and DC-DC converter. It will receive signal from the controller to output how many current needed from the fuel cell. Fuel cell and battery will supply the requested power to the motor. A Battery Management System also can found in here where it used to estimate the SoC of the battery. Then the SoC of battery information will be sent back to the controller.

Simulator of the FCHV

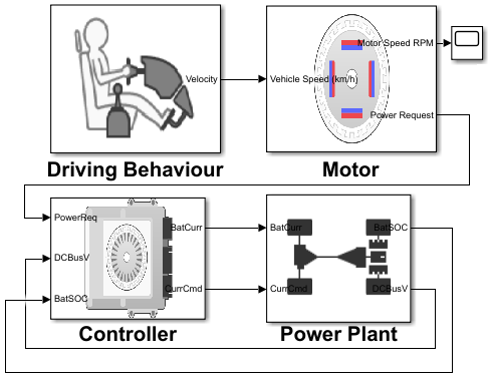

The simulator of the FCHV including the energy management system and battery management system using MATLAB/Simulink is shown below:

1. Driving behaviour This is the input of the system. The driving behaviour is translate as a velocity of the vehicle in km/h.

2. Motor From the velocity of the vehicle, the power request is determined. The parameters of the vehicle such as radius of the wheels, weight of the vehicle are based on the Fuel Cell Hybrid Model.

3. Controller The controller is the main part of this project where we need to implement the Energy Management Strategy to regulate the power flow between fuel cell and battery. It will determine optimal current command and send the signal to the DC-DC converter in the Power Plant.

4. Power Plant The Power Plant consists of Fuel cell, battery and DC-DC converter. It will receive signal from the controller to output how many current needed from the fuel cell. Fuel cell and battery will supply the requested power to the motor. A Battery Management System also can found in here where it used to estimate the SoC of the battery. Then the SoC of battery information will be sent back to the controller.

Result & Discussion

Performance of Energy Management Strategy

The performance of the PCU was compared with Rule-based strategy in terms of total hydrogen fuel consumption, battery SoC.

| Power demand | SoC battery | Condition | Current command, A |

|---|---|---|---|

| Negative | SoC < 40 | Regenerative braking | 0 |

| Negative | 40 < SoC < 60 | Regenerative braking | 0 |

| Negative | SoC > 60 | Regenerative braking | 0 |

| Zero | SoC < 40 | Fuel cell charges the battery | 3 |

| Zero | 40 < SoC < 60 | Fuel cell charges the battery | 2 |

| Zero | SoC > 60 | No power flow | 0 |

| Positive | SoC < 40 | Fuel cell mode | 4 (maximum) |

| Positive | 40 < SoC < 60 | Hybrid mode | 2 |

| Positive | SoC > 60 | Battery mode | 0 |

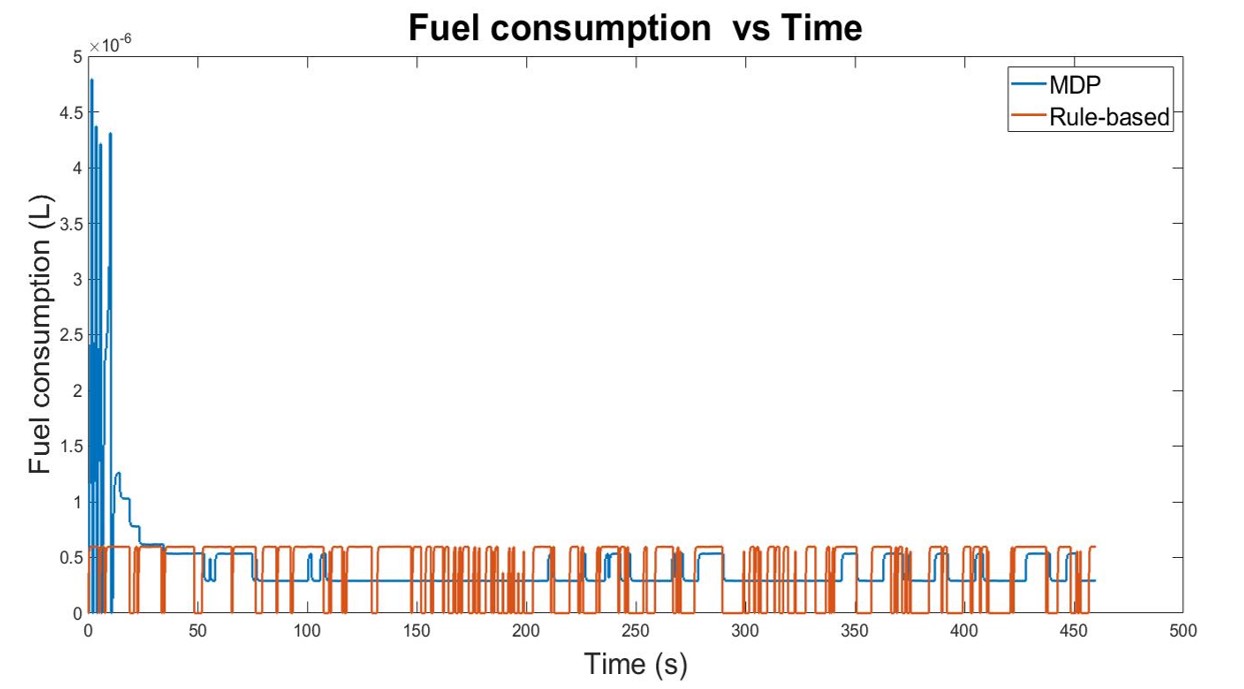

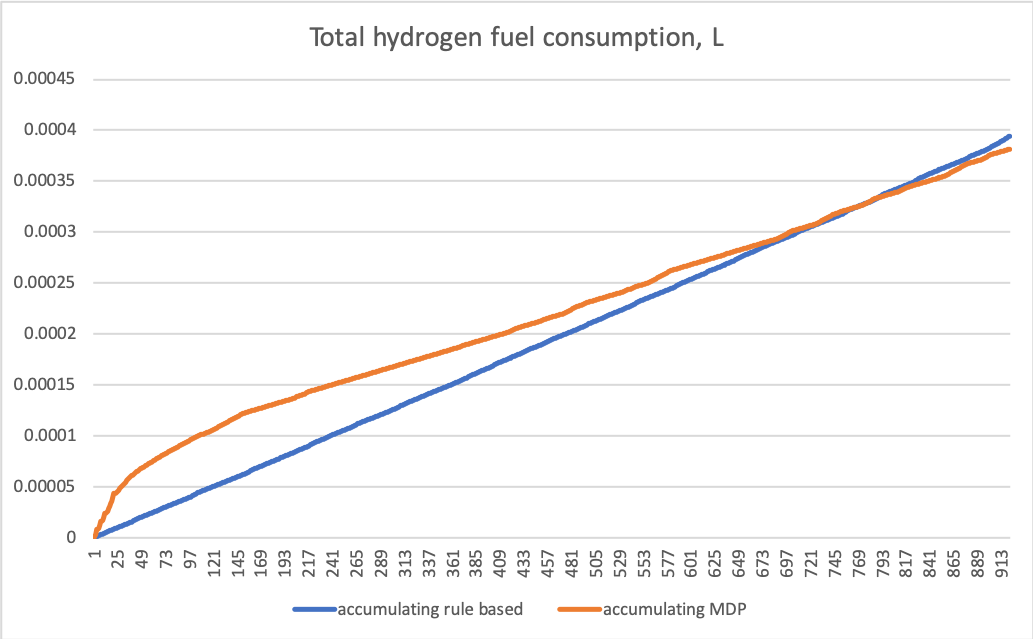

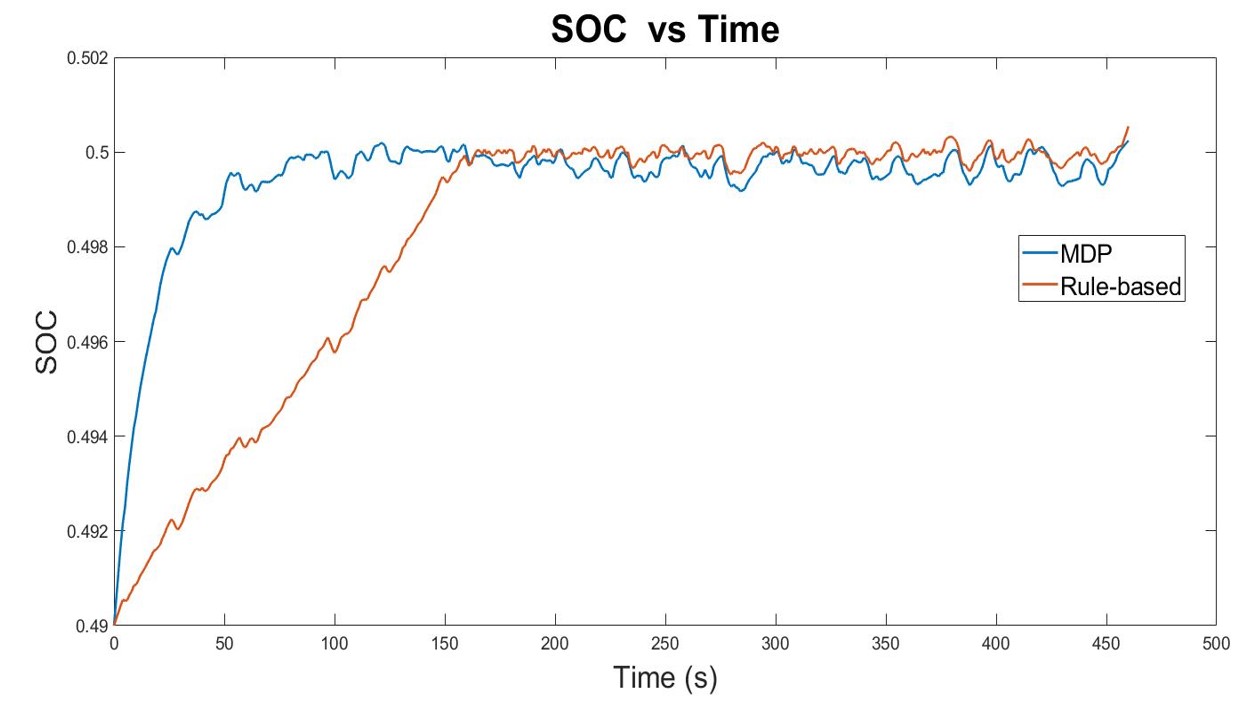

The MDP strategy consumes more hydrogen fuel at the start to reach the SoC reference faster compared to rule-based strategy. Then it will maintain the SoC at the reference which is 50%. Using the same driving cycle, the total fuel consumption for MDP strategy is lower than rule-based strategy.

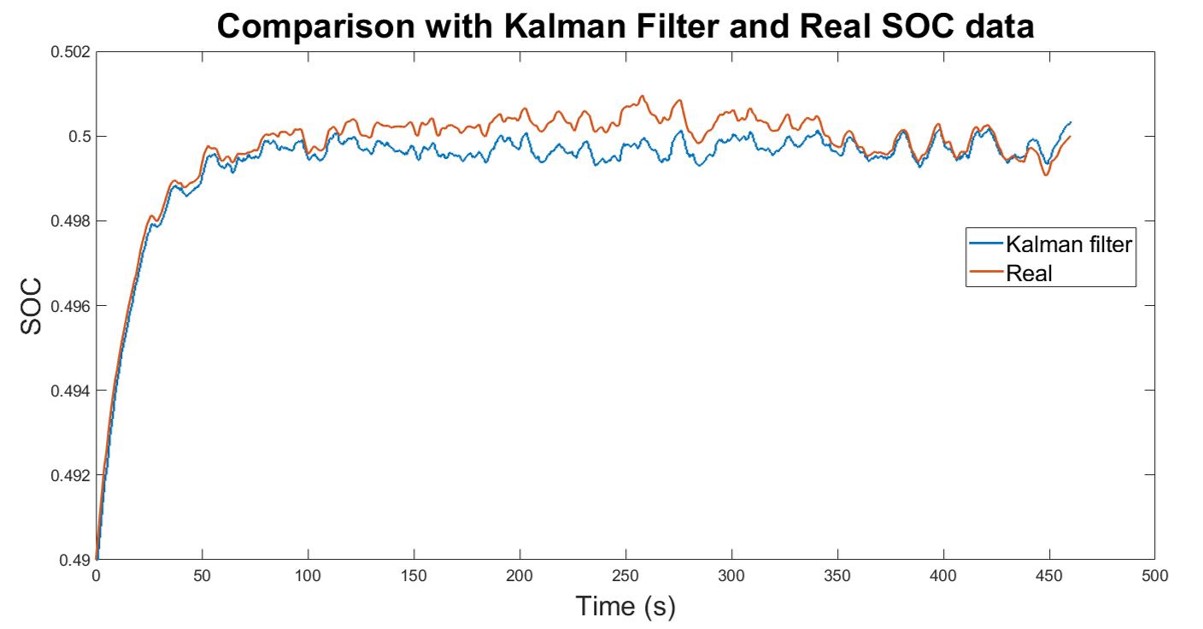

Performance of Battery Management System

The analyse the performance of the our Battery Management Strategy, we compared the estimation SoC by Kalman Filter with real SoC reading from the battery model. The estimation curve has small value of deviation with the real SoC reading. This can ensure the control action determined by the PCU is accurate and correct.

Conclusion & Future Work

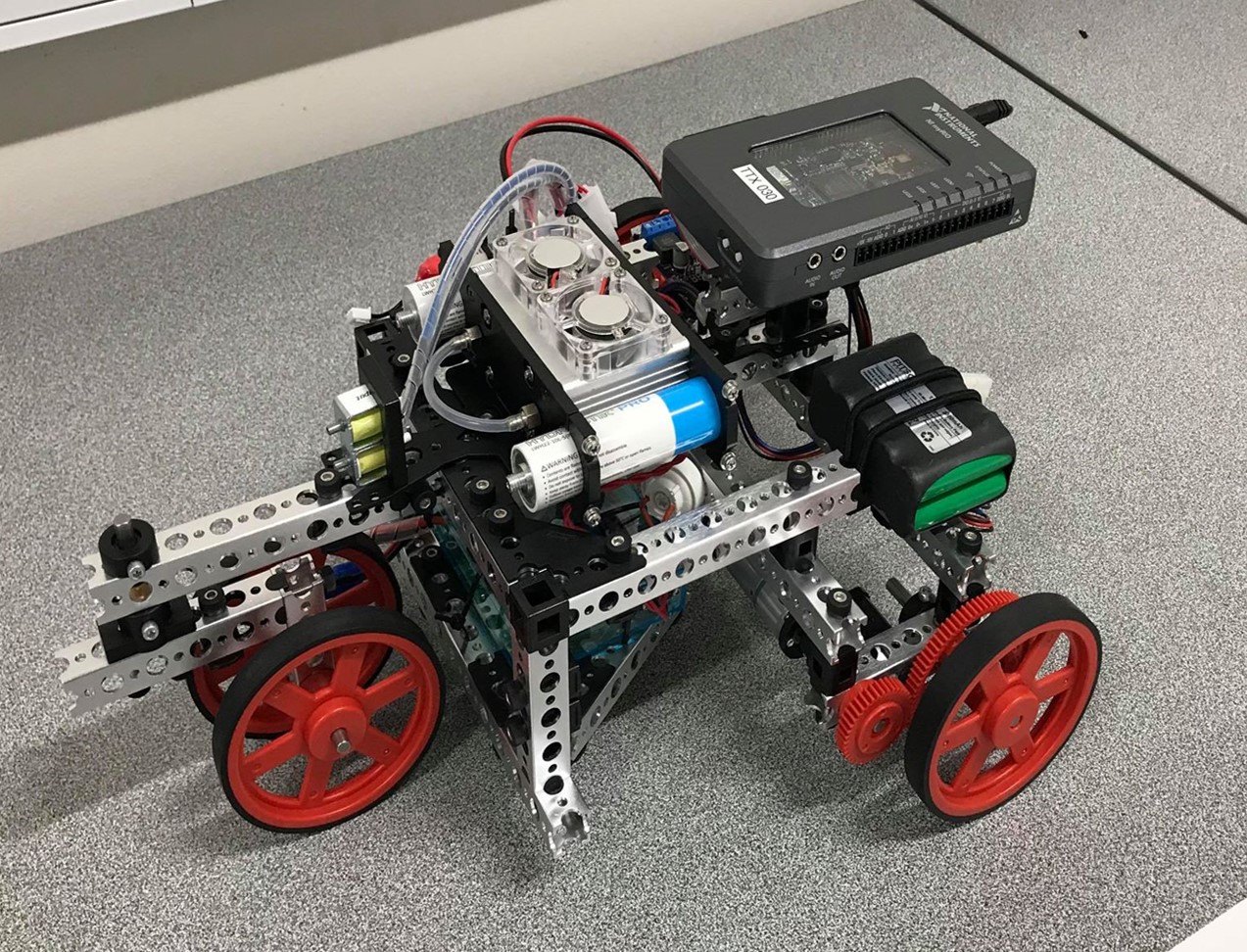

The controller was developed by implementing a Markov Decision Process as the strategy. The Battery Management System was introduced the application of Extended Kalman Filter. The fully functional simulator was developed in Simulink to analyse the performance of the controller and the Battery Management System. This proposed strategy is accepted to continue its development by implementing it to the actual model of Fuel Cell Hybrid Vehicle which is shown below. This strategy can be improved more by using online optimisation problem solving which can be more robust compared to offline.

Reference

- [1] D. Shen, “Week 1 Presentation,” in Project introduction, 06-Jun-2019.

- [2] A. L. Dicks, D. A. J. Rand, and J. Larminie, Fuel cell systems explained. Chichester: Wiley, 2018.

- [3] Y. Huang, H. Wang, A. Khajepour, H. He, and J. Ji, “Model predictive control power management strategies for HEVs: A review,” Journal of Power Sources, vol. 341, pp. 91–106, 2017.

- [4] K. Simmons, Y. Guezennec, and S. Onori, “Modeling and energy management control design for a fuel cell hybrid passenger bus,” Journal of Power Sources, vol. 246, pp. 736–746, 2014.