Projects:2014S1-37 Wireless Monitoring and Control of Wine Fermentation Process

During the process of wine fermentation, the grape will produce sugars, flavour compounds, alcohol and nutrients, which requires reliable temperature control to give winemakers best possible use of grapes. Temperature control enables the wine ferments in reasonable speed to avoid such bad phenomena happen: if the speed is low, the yeast die before all of the sugar are consumed or desirable flavours is not extracted; if the speed is high, the wine may contain sulphides, mercaptans, higher alcohols and other undesirable characters that make the wine with low quality [1].

Contents

Project Information

During the project year, the temperature and specific gravity are measured.

Based on a research of Dr Frank Schmid, the temperature in winemaking is important. As a highly variable parameter, the fermentation temperature would influence the rate of yeast growth, metabolism and would have a resulting impact on wine quality. According to this research, it is necessary that monitor the temperature during wine fermentation process [2].

According to the glossary of winemaking terms, the importance of the specific gravity is that specific gravity would indicates how much dissolved sugar is present for conversion to alcohol by yeast, what that proof will be, and how much sugar to add to raise the finished proof to a specific level. Based on an experienced winemaker, when specific gravity is less than 1.010, the winemaking process would be at the racking stage. The specific gravity would give signals of winemaking process to winemakers [3]. The importance and function of the specific gravity make it necessary to be measured during wine fermentation process [4].

There is one more important reason that project team would like to measure the temperature and specific gravity in the wine tank. The specific gravity could be corrected by temperature. The correction equation could be presented as:

Cg = Mg × ((1.00130346 - 0.000134722124 × Tr + 0.00000204052596 × Tr2 - 0.00000000232820948 × Tr3) / (1.00130346 - 0.000134722124 × Tc + 0.00000204052596 × Tc2 - 0.00000000232820948 × Tc3))

The Cg is the corrected specific gravity, the Mg is measured specific gravity, the Tr is temperature at time reading and the Tc is the calibration temperature.

Project Aims

- The project team aims to use WSN (Wireless Sensor Network) to measure, collect and transmit the temperature and specific gravity data during the wine fermentation process in the vats.

- The project team aims to develop a GUI (Graphic User Interface) on Matlab to help users view the temperature and specific gravity data.

- The GUI will also be developed to analysis data and help winemakers to make the wine fermentation decisions.

Project System Design

Temperature Sensor

The LM35 sensors are used as a temperature sensor in this project.

Temperature Sensor: LM35CAH

Measurement Range: -40℃ - 110℃

Accuracy: ± 0.5℃

LM35 Temperature Sensor Array

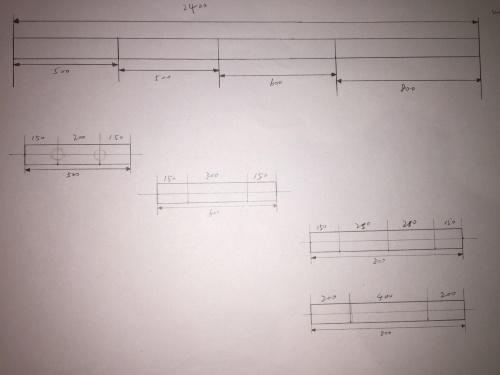

A new sensor array that use LM35 would be built this year.

Project team will use a long stainless steel tube to make probes that hold LM35 temperature sensors.

The long tube will be cut into four pieces and each piece will be built into a probe.

First probe with 0.5 meters will hold no sensor because the top of wine tank will be full of pomace. The rest three probes are in the length of 0.5 meters, 0.6 meters and 0.8 meters. There will be two sensors on each probe. The different combination of probes would fit into different size of wine tanks.

Because of the time limitation, the probe will be built in next year or later.

This is a sample of the temperature probe which will be used for the exhibition.

Specific Gravity Sensor

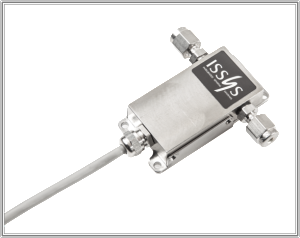

The MicroLDS is used as a specific gravity sensor in this project.

Specific Gravity Sensor: microLDS

Measurement Range: 0.6 – 1.3 g/cm3

Accuracy: 0.0005 g/cm3

Small Peristaltic Pump

A small peristaltic pump is used to extract wine from wine tank into the specific gravity sensor.

Drive: DC Motor

Operating Voltage: 5V

Current at Full Speed: 280mA

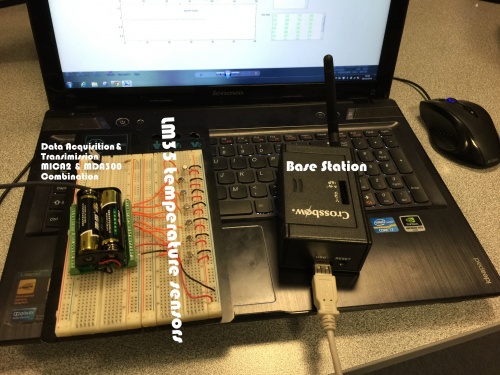

Wireless Sensing Network

Sensors, data acquisition board (MDA300), transmission mote (MICA2) and base-station composition the wireless sensing network.

- Wireless Sensor Network Part One

MDA300 Data Acquisition Board

Functionality: Temperature and Specific Gravity data collection

Extended Functionality: Sleep Mode

- Wireless Sensor Network Part Two

Radio Board

Available Radio Band: 2.4 GHz / 433MHz

Functionality: Wireless data transmission

- Wireless Sensor Network Part Three

Base Station

Available Radio Band: 2.4 GHz / 433MHz

Connection: USB serial port

Functionality: Receive data from radio board and transmit the data to computer

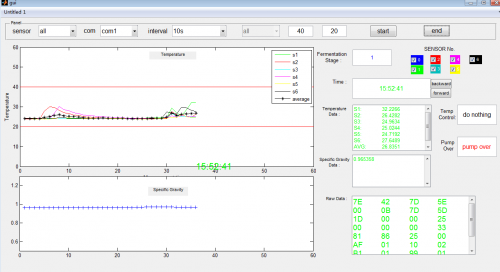

Graphic User Interface

GUI known as Graphic User Interface. Project team develops a GUI in Matlab that could read and plot data from Base-station in real time. Furthermore, GUI could analysis the received data and give feedback to winemakers such as cooling or heating or pump over in the wine tank.

Data Read Head

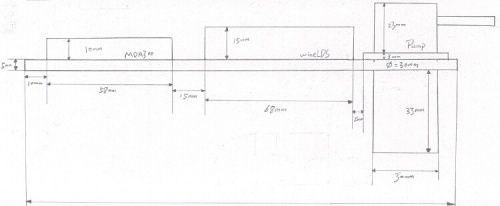

The D-R-H (Data Read Head) is the core part of the whole system. This part will hold the data acquisition board, specific gravity sensor and pump. The output from temperature sensor will be connected to data acquisition board by wires.

Top view of the design.

Side view of the design.

Project System Implementation

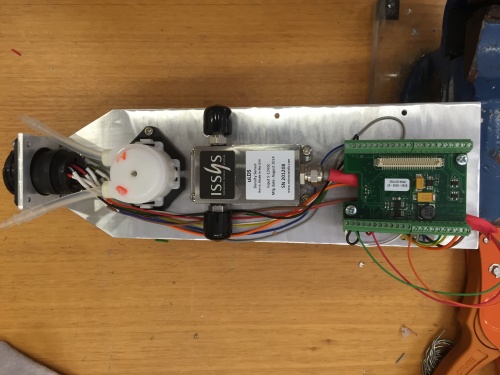

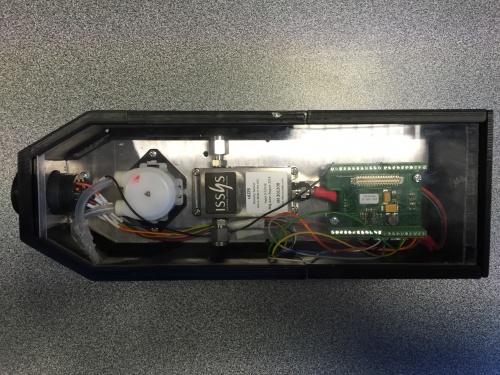

School's workshop helped project team to implement their design to real product.

DRH without cover

DRH with full cover

The implemented hardware is named as Data Read Head (DRH). As the core part of the project, the DRH has achieved temperature and specific gravity measurement, data collection and transmission. MDA300 has achieved sleep mode to save power.

Reference

[1] D.C. Ranasinghe, N.J.G. Fallkner, C. Pan, H. Wu. “Wireless sensing platform for remote monitoring and control of wine fermentation,” IEEE International Conference on Intelligent Sensors, 2-5 April, Melbourne, VIC, 2013.

[2] F. Schmid, V. Jiranek, G. Valentine, the Importance of Temperature in Winemaking, The University of Adelaide. Available: https://agwine.adelaide.edu.au/winemicro/research/beverage/temperature/

[3] J. Keller, Glossary of Winemaking Terms. Available: http://winemaking.jackkeller.net/glossary.asp

[4] M. Williams. (2013, Nov). How to know when to rack your wine. Winemaker’s academy. Available: http://winemakersacademy.com/when-to-rack-wine/

Team

Group members

- Mr Feiyu Yin

- Mr Shicheng Zhang

Supervisors

- Dr Said AI-Sarawi

- Dr Damith Ranasinghe

Resources

- Bench 29

- RTD temperature sensor array

- Wireless Sensor Network Kit

- Application software

- MoteView

- MoteWork

- Matlab

- Standard PC