Projects:2014S1-53 Object Profiling for Custom Wheelchair Seating and Pressure Care

The aim of this project is build on a three year long current research in 3D object scanning (Kinect or line laser 3D scanning) and printing techniques to provide a low cost solution for customising seating of a wheelchair and a customised insole.

Contents

Project Information

Motivation and Background

A significant problem faced with individuals with disability is the uncomfortable nature of wheelchair or insoles of shoes, and in some cases there an urgent need to have the seat of these wheelchair customised for each individual. However, this process is associated with a significant cost, take a certain minimum period amount of time and can be prohibitive. Many of the current methods of profiling takes approximately 4 week from analysis to production and delivery.[1] The aim of this project is build on a three year long current research in 3D object scanning (Kinect or line laser 3D scanning) and printing techniques to provide a low cost solution and reduced waiting times for a customised seating of a wheelchair and a customised insole at almost no loss in quality.

Hardware and Software used

- Xbox 360 Kinect[2]

The 3D scanner of choice for this project is the Microsoft Xbox 360 Kinect, as it was used previously and due to its low cost for the hardware. The Kinect uses the concept of structured light by using an array of infrared dots and a CMOS sensor, an optical sensor and using the combination of the two to estimate the approximate distance of objects from the Kinect.

- MATLAB (32-bit)

MATLAB is chosen as the coding software due to available code written by the previous groups and many of the current group members are comfortable in using the software. Some algorithms where produced on MATLAB by the previous group and it is used for the current project. The 32 bit version of the software is used due to the requirement of the MATLAB executables only executable on 32 bit system or 32 bit version of MATLAB.

- Xbox 360 Kinect Drivers

These drivers are essential to be able to use the Kinect with the computer and with the software on MATLAB.

- MATLAB Kinect executables

The MATLAB Kinect executables are the only means of having the hardware communicate and send information into MATLAB. Without these executables, some research and development is needed for the production of custom drivers to talk directly to MATLAB and would require the reconditioning of algorithms using the executables.

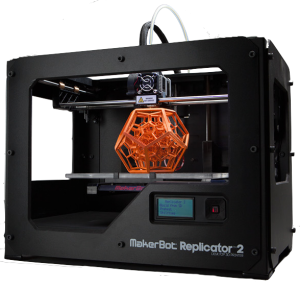

- 3D Printer

The 3D printer is to produce the output of the project, in this case, a customised seat or customised insole.

- Standard Computer (Windows)

Any windows computer with the ability to run MATLAB and interface with the Kinect can be used. Other operating systems are not compatible with the MATLAB executables.

Project Aims

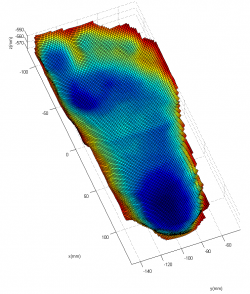

- To be able to obtain a profile of a back/foot.

This involves the ability to be able to produce some code and utilising a 3D scanner, which is in this case a Xbox 360 Microsoft Kinect". This hardware will be the main hardware used to capture the profile of the person's back or foot.

- To customise a wheelchair seat and insoles for individuals with disabilities.

This involves manipulation of the profile data collected from the 3D scanner where this manipulation will be done on MATLAB. MATLAB is used to continue the use of algorithms produced by previous researchers and reduce some time for research.

Project Requirements

- Ability to obtain a scan resolution of 3-5mm or less.

- Manipulate the profile to correct disability.

- Convert and print profile to obtain a customised 3D seat/insole.

Challenges

There is a wide range of challenges associated with this project which all have different methods of analysis and depiction of the challenge involved. The challenges associated with this project are;

- The constraints of the hardware.

At the beginning of the year, the Xbox 360 Kinect was the nominated hardware to use as the 3D scanner and this hardware is 3 years old (2 years since the release of drivers for windows) which only has a 320x240 resolution on both the IR camera and the optical camera. The Kinect also has a limiting distance that the sensor can accurately measure the distance of the object in view where the accuracy falls proportionally to distance. In mid 2014, Microsoft released the Kinect 2 with sensor improvements[3] but as the drivers for the hardware was only recently release, the choice of upgrading the hardware was not possible due to time limitations on the project.

- Deformation of the back or foot under pressure

The back and foot surfaces can be very easily influenced by pressure and therefore the capture of this influence is important as profiling the back or foot without this pressure influence may result in a incorrect customised seat/insole and therefore uncomfortable to the user and may even cause greater injury to the person. Research on methods on capturing this pressure influence is critical to the project to ensure the sea/insole is correctly suit to the person developed for.

- Analysis and manipulation of the profile

This requires coding skill in MATLAB as it is the choice of software and all of the data to be collected will be in the form of floating cloud point data. The profile will be required to be manipulated to remove unwanted objects, noise and detect the rotation of the back/foot and produce a corrected rotation.

Work Allocation

Edward Chau

- Code to correctly obtain a profile of the back or foot.

- Remove noise and background from the subject.

- Generate algorithms to detect the rotation and orientation of the back/foot.

- Produce a correctional seat/insole model for the back/foot.

- Produce a printable model.

Weionn Tang

- Research and investigate possible materials to be used to detect pressure influence.

- Collect back and foot profiles using the Kinect.

- Quantitatively investigate the scaling/skewing factors of the Kinect.

- Produce rigs used to capture required data.

Simon Shi

- Investigate and develop an algorithm to segmentate large data to suit small 3D printers.

- Investigate possible production materials for the products.

Team

Group members

- Mr Edward Chau

- Mr Simon Shi

- Mr Weionn Tang

Supervisors

- Dr Said AL-Sarawi

- Dr Danny Gibbins