Projects:2016s1-146 Antonomous Robotics using NI MyRIO

Contents

Introduction

Supervisors

Dr Hong Gunn Chew

A/Prof Cheng-Chew Lim

Honours Students

Thomas Harms

James Kerber

Mitchell Larkin

Chao Mi

Project Details

Each year, National Instruments (NI) sponsors a competition to showcase the robotics capabilities of students by building autonomous robots using one of their microcontroller and FPGA products. In 2016, the competition focuses on the theme 'Hospital of the future' where team robots will have to complete tasks such as navigating to different rooms in a hospital setting to deliver medicine while avoiding various obstacles. This project investigates the use of the NI FPGA/LabView platform for autonomous vehicles. The group will apply for the competition in March 2016. More information about the NI robotics competition is found at http://australia.ni.com/ni-arc LabView programming knowledgement would be a key advantage in this project. This project builds on the platform designed and built in 2015

Project Proposal

To have a better understanding of the project and to distribute the workload amongst the team, the robot system has been broken down into the following sections:

Mechanical Construction Artificial Intelligence (Software), Robot Vision and Range Finding, Localisation, Movement system, Hardware design and installation, Medicine dispenser unit, Pathfinding/Navigation Control, Object detection, Mapping Movement tracking.

By creating a set of clearly defined work activities, each team member will be able to design and develop the required functionality for their respective sections.

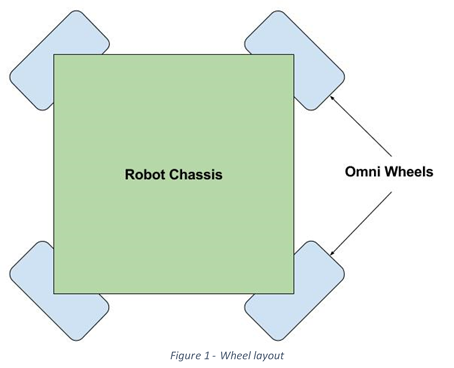

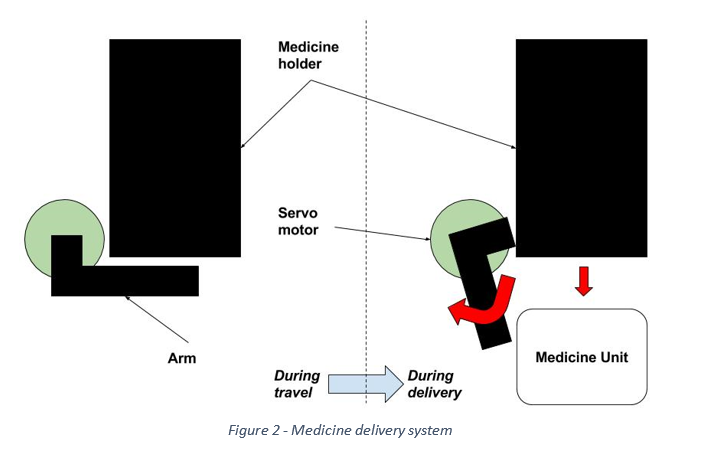

The mechanical construction will focus on the design and assembly of the robot itself. This process will involve deciding on the robot dimensions, motors, sensors and medicine delivery system. Current research and development has been made to the movement system and a four omnidirectional wheeled approach is being prototyped. This prototype will demonstrate a robot with the ability to move in any direction easily without the need to rotate before any translation takes place. Figure 1 shows the layout that will be used for this robot design. The mechanism for delivering the medicine units shall be similar to the design from last year’s University of Adelaide team. Figure 2 demonstrates how this medicine delivery shall work.

The vision and range finding systems for this robot shall consist of an RGB-D camera and an array of ultrasonic sensors. The camera shall be used to implement object detection, while the sensors shall measure proximity to the surroundings. These systems in conjuncture with each other shall allow collision avoidance to be achieved. The localisation system shall be realised through the use of optical flow sensors. These sensors shall measure the direction of flow of the surface below the robot in order to quantify which direction the robot is moving, providing full localisation functionality.

The delivery system, combined with the ease of movement provided by the wheel layout, shall allow for our robot to quickly and efficiently traverse the competition track and deliver the medicine units to the required areas. The use of the mentioned sensors shall provide collision avoidance and localisation, resulting in a robot that can safely and reliably complete the goals required for the competition. In conclusion, this design aims to achieve fully autonomous behaviour in a hospital setting.

Project Progress

Movement System

Current Progress

After initial research early on in the project the group decided upon the four-wheeled setup. If this system can be produced, it could provide the robot with the capability to move about the map quickly and to dispense medicine even faster.

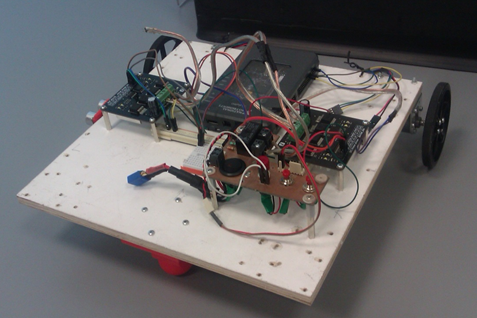

An initial prototype has been constructed through the use of a single 300mm x 300mm wooden base which various wheels and sensors have been attached to. The wheel configuration in this prototype is the two bi-directional wheeled system coupled with a ball bearing slider. The Omni-wheeled design was not implemented first as the team wanted to make a simple prototype to test all the systems simply. In addition, there was a considerable delay in acquiring the Omni-wheels needed.

Manual control was implemented soon after the prototype robot was developed to allow the team to test the sensors and their effectiveness in a moving environment. In addition, a form of automatic control has been developed to avoid obstacles and move past/around them.

Future Progress

The design and construction of a new prototype for testing the 4 wheel configuration. This will be separate from the current prototype and will enable the team to compare the two designs and come to an agreement on the configuration that will be used for the final build robot. The new prototype will consist of a 300mm x 300mm aluminum or Perspex base and the four wheel Omni-wheel design discussed.

A likely inclusion to the new prototype will be an upgrade to a two tier system design. This will involve an additional 300mm x 300mm aluminum or Perspex panel which will be mounted a short distance directly above the first base. This will provide an upper level which various sensors and the medicine delivery system can be mounted onto.

Localisation System

The localisation system is built on optical flow, and computer vision. Optical flow provides a high update rate but is susceptible to noise and accuracy drift. Computer vision observations are registered to the competition track. While the update rate is much lower, it has zero drift. A hybrid was built to obtain a fast update rate from the optical flow system, while counteracting drift errors with the computer vision system. Both these components are described in the following sections.

Optical Flow Sensors

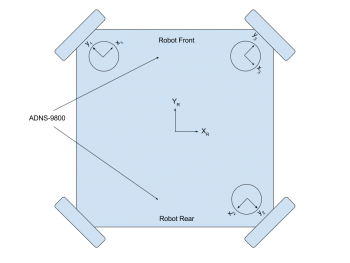

Three ADNS-9800 optical flow sensors were used in the project. These use a laser for illuminating the surface meaning higher accuracy than other illumination methods. Also, they can handle speeds of travel up to 3.81 meters per second. This is more than enough to satisfy the robot's top speed (approximately 1 meter per second). A photo of the sensor module is shown here.

The optical flow system was analysed through simulation in MATLAB (see the figure below for an example of the output). This confirmed the drift errors mentioned earlier. Furthermore, it was found that discrepancies between sensor measurements of approximately 10mm was enough to cause heading errors of up to 8 degrees, and position errors up to 46cm and 70cm along x and y in the global coordinate system. This affirmed the need for the drift correction system.

Through testing it was found that the maximum clearance between the bottom of the sensor lens and ground surface is 3mm. This left little room for bumps in the surface area. In order to keep the sensors clear of bumps and maintain a near constant height above the surface, the sensors are mounted directly beneath the motors. Whenever a wheel travels over a bump, the sensor is raised and therefore clears it. To fit the cables attached to the sensor module PCBs, the sensors were mounted with their y-axes pointing out along the axles of the wheels (see the figure below).

Through experimentation with the sensors, it was found that three levels of calibration were required. Firstly, the resolution of the sensors must be found. The resolution is affected by the height it is mounted above the ground, and the angle which the laser projects to the surface. As the sensor height above ground is increased, it's effective resolution is decreased. When the height is decreased, the resolution increases until it reaches the resolution configured in the device. Since the sensors are suspended above the ground, the resolution must be calibrated.

For the second factor, the angle of the laser sensor causes the resolutions to vary depending on the direction of translation. It was found that motion of a fixed distance along the positive y-axis was measured slightly greater than the same distance but along the negative y-axis. This also held true for the x-axis. This result meant that 4 resolution calibration factors were ideally required. In practice it was found that only one per x and y axis was sufficient.

The next level of calibration was for the angular and displacement offsets of the sensors - theta, phi and r components (see the picture below). For higher accuracy these offsets were measured through data collection, and resolving the constants from the 3DOF estimation equation. In this step, the robot was moved in fixed translations and rotations. The algorithm in LabVIEW used this recorded data to solve for the offsets.

The highest level of calibration scaled the translations along the x and y axis as well as rotations to ensure that distances and angles were measured accurately. As hinted in the first level of calibration, the robot's measurements differ between +y and -y translations, and +x and -x translations. These measurements were calibrated so positive and negative movements along the x and y axes were equal.

Computer Vision System

The computer vision system was built on the range data produced by the Xbox Kinect. See the Xbox Kinect section for more details.

Heading Correction System

As seen in the simulation data previously, the heading of the optical flow system is inaccurate and greatly effected by measurement errors. In practice this was also found to be the case. From testing, the heading was found to be far too inaccurate for use. For instance, the average drift over 1.5m was 30 degrees. The resulting accumulated position errors of the robot were therefore 20cm per meter.

In each case, it was found that while the heading estimation was greatly effected by the measurement errors, the translation estimation was not (see figure (c) in the MATLAB simulation picture above). At this stage, an inertial measurement unit (IMU) could have been added to the system to provide a more reliable source of heading. Due to the competition nearing only one month away, a new tactic involving the Xbox Kinect and motor control was used instead of the IMU.

It was found that by allowing the robot to move without rotations, the robot's position estimation in the robot's local coordinate frame, with a fixed assumed heading could be used. The motor controller managing translations was designed to move the robot with minimal heading changes. To correct for slight heading drifts, and to ensure the robot stays on path, the Xbox Kinect was used to align the robot to key points around the track. More information on the Xbox Kinect alignment can be found in the appropriate section on this page.

Conclusion

The end solution of the localisation system differed from the initial plan in that heading was not measured in the final system, and there was a heavy dependence on the performance of the motor controller. Even with the issues discovered while designing and testing the system, the localisation system was able to successfully measure transnational distances within the accuracy required by the project.

Future improvements for the localisation system would involve;

- Investigate using an IMU for heading measurements, and combine this with the translation estimation from the optical flow sensors.

- Improve the computer vision system to correct position as well as heading.

Path Planning

The path planning The development of the autonomous robot is moving fast and plays significant roles in science and manufacturing fields. An autonomous robot is a robot that is able to perform tasks by its own; particularly they are designed in certain areas and fields. The robot is able to perform repetitive tasks while can make its own decisions to make sure it do not damage any object or human or be damaged in unexpected situations. For example, famous autonomous vehicle NASA Mars Rover Opportunity and Spirit can make their own decisions to make additional observation of rocks by using their camera sensors to check the rocks that satisfy certain criteria.[ The trending of autonomous robot expands on many fields, such as in logistics delivering goods, military combat situations and manufacture goods. In the future, it is expected that the autonomous robot take over low skill labour jobs, so people can focus in more senior level of work.

Many researchers across the world are working on the path planning algorithm of autonomous robot. Numeral algorithms have been invented and further improved to calculate optimal path(shortest path) from start area to target areas without collision with obstacles. In this Project, pointBug path planning algorithm is used and implemented in LabVIEW for the autonomous robot system.

PointBug algorithm is a point to point path planning algorithm. It plans the path based on the readings from Kinect camera sensor and from start point to target point. The Kinect camera sensor returns magnitudes and angles in the one dimensional array form. Because the readings from Kinect are randomly allocated and cumbersome, a technic of data reduction is used to illuminates all the useless and meaningless data such zeros or NaN(Not a Number) in magnitudes and angles arrays. Next, the order of angles array is sorted so the element from the array starts at 68 degree to 111 degree. Then many similar values are filtered out and only use one of the set of similar values to represent the rest ones. Each element in magnitudes array was corresponding to the element in angles array in the same order. At this stage, the elements in these two arrays are much smaller and all arrays are in order to ease the process for the path planning algorithm.

The robot uses its sensors to check special points called sudden point. A sudden point is a point that the sensor detects change from the nearest obstacle to free space. To help to understand the concept, the figure is used to explain the sudden point.